Growing Focus on Predictive Maintenance

The Automated Ultrasonic Testing Market is increasingly influenced by the growing focus on predictive maintenance strategies across various sectors. Organizations are recognizing the value of proactive maintenance approaches to minimize equipment failures and reduce operational costs. Automated ultrasonic testing plays a crucial role in predictive maintenance by enabling early detection of potential issues in machinery and structures. This capability not only enhances safety but also extends the lifespan of assets. As industries strive to optimize their maintenance practices, the demand for automated ultrasonic testing solutions is expected to rise. Market analysts suggest that the predictive maintenance market could reach USD 12 billion by 2027, with ultrasonic testing being a key component. This trend indicates a shift towards more sophisticated maintenance strategies, further driving the growth of the automated ultrasonic testing market.

Regulatory Compliance Driving Market Growth

The Automated Ultrasonic Testing Market is significantly influenced by stringent regulatory compliance requirements across various sectors. Industries such as oil and gas, aerospace, and construction are mandated to adhere to rigorous safety and quality standards, necessitating the use of non-destructive testing methods like ultrasonic testing. Compliance with international standards, such as ASTM and ISO, is essential for ensuring product integrity and safety. As companies strive to meet these regulations, the demand for automated ultrasonic testing solutions is expected to rise. This trend is further supported by the increasing emphasis on safety protocols and risk management strategies, which are becoming integral to operational practices. Consequently, the market is likely to witness sustained growth as organizations invest in advanced testing technologies to comply with evolving regulatory frameworks.

Increased Demand for Non-Destructive Testing

The Automated Ultrasonic Testing Market is benefiting from a heightened demand for non-destructive testing (NDT) methods. As industries seek to enhance quality assurance and minimize operational risks, ultrasonic testing has emerged as a preferred choice due to its ability to detect internal flaws without damaging the material. The growing awareness of the advantages of NDT, such as cost-effectiveness and reliability, is driving its adoption across various sectors, including manufacturing, automotive, and energy. Market data indicates that the NDT market is projected to reach USD 3 billion by 2026, with ultrasonic testing accounting for a substantial share. This increasing demand for NDT solutions is likely to propel the growth of the automated ultrasonic testing market, as companies invest in advanced technologies to ensure product quality and safety.

Rising Investment in Infrastructure Development

The Automated Ultrasonic Testing Market is poised for growth due to rising investments in infrastructure development projects. Governments and private entities are increasingly allocating funds for the construction and maintenance of critical infrastructure, such as bridges, railways, and pipelines. These projects necessitate rigorous testing to ensure structural integrity and safety, thereby driving the demand for automated ultrasonic testing solutions. The need for efficient and reliable testing methods is paramount in preventing failures and ensuring compliance with safety standards. As infrastructure projects expand, the market for automated ultrasonic testing is expected to flourish, with projections indicating a potential increase in market size by 15% over the next five years. This trend underscores the importance of advanced testing technologies in supporting infrastructure resilience and sustainability.

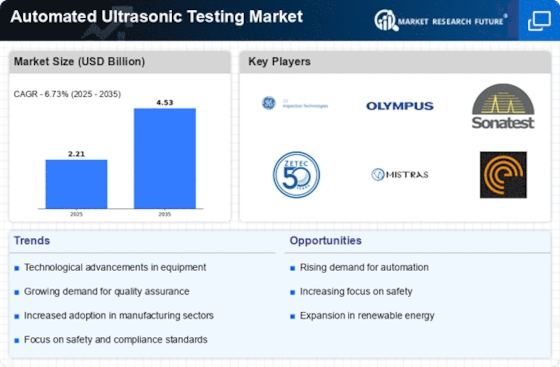

Technological Advancements in Automated Ultrasonic Testing

The Automated Ultrasonic Testing Market is experiencing a surge in technological advancements that enhance testing accuracy and efficiency. Innovations such as phased array technology and automated scanning systems are revolutionizing the way ultrasonic testing is conducted. These advancements allow for real-time data analysis and improved defect detection capabilities, which are crucial in industries such as aerospace and manufacturing. The integration of artificial intelligence and machine learning into ultrasonic testing systems further optimizes performance, enabling predictive maintenance and reducing downtime. As a result, the market is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 7% in the coming years. This trend indicates a robust demand for advanced automated ultrasonic testing solutions across various sectors.