Technological Innovations

Technological advancements play a pivotal role in shaping the Automatic Tube Labelling System Market. Innovations such as artificial intelligence, machine learning, and advanced imaging technologies are enhancing the capabilities of labelling systems. These technologies enable real-time monitoring and adjustments, ensuring optimal performance and accuracy. As manufacturers seek to differentiate their products, the integration of cutting-edge technologies into labelling systems is becoming increasingly common. This trend not only improves operational efficiency but also enhances the user experience, making automated systems more appealing to a broader range of industries. The continuous evolution of technology is likely to drive market growth in the coming years.

Emphasis on Cost Efficiency

Cost efficiency remains a driving force in the Automatic Tube Labelling System Market, as organizations seek to reduce operational expenses while maintaining high-quality standards. Automated labelling systems offer a viable solution by minimizing labour costs and reducing the likelihood of errors that can lead to costly recalls. Companies are increasingly recognizing the long-term savings associated with investing in automated solutions. Market analysis suggests that businesses can achieve a return on investment within a few years of implementing these systems. As cost pressures continue to mount, the demand for efficient labelling solutions is expected to rise, further propelling the growth of the market.

Growth in Biopharmaceuticals

The biopharmaceutical sector is witnessing rapid expansion, which significantly impacts the Automatic Tube Labelling System Market. As the production of biologics and biosimilars increases, the need for precise and reliable labelling becomes paramount. Automated labelling systems are essential for managing the complexities associated with biopharmaceutical products, including varying sizes and shapes of tubes. The market for biopharmaceuticals is expected to reach USD 500 billion by 2026, indicating a substantial opportunity for labelling system providers. This growth is likely to drive innovation and investment in automated labelling technologies, ensuring that they meet the evolving needs of the biopharmaceutical industry.

Rising Focus on Traceability

Traceability has emerged as a critical factor in the Automatic Tube Labelling System Market, particularly in sectors such as healthcare and food safety. The increasing emphasis on tracking and tracing products throughout the supply chain necessitates robust labelling solutions. Regulatory bodies are mandating stringent traceability requirements, compelling organizations to invest in advanced labelling technologies. This trend is likely to drive the market forward, as companies seek to comply with regulations while ensuring product integrity. The integration of automated labelling systems not only enhances traceability but also streamlines operations, thereby contributing to overall efficiency and compliance.

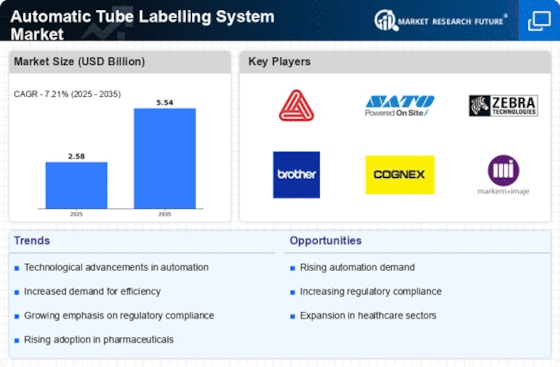

Increased Demand for Automation

The Automatic Tube Labelling System Market is experiencing a notable surge in demand for automation across various sectors, particularly in pharmaceuticals and laboratories. This trend is driven by the need for enhanced efficiency and accuracy in labelling processes. As organizations strive to minimize human error and optimize productivity, the adoption of automated labelling systems becomes increasingly appealing. According to recent data, the market for automated labelling solutions is projected to grow at a compound annual growth rate of approximately 7% over the next five years. This growth reflects a broader shift towards automation in manufacturing and laboratory environments, where precision and speed are paramount.