Growing Focus on Safety Features

Safety remains a paramount concern in the Automotive Plastic Fuel Tank Market, influencing design and manufacturing practices. The increasing emphasis on vehicle safety features has led to the development of advanced plastic fuel tanks that offer enhanced protection against leaks and impacts. Innovations such as multi-layered tank designs and improved sealing technologies are being implemented to meet safety standards. Additionally, the rising number of safety regulations and consumer awareness regarding vehicle safety are driving manufacturers to prioritize the development of safer fuel storage solutions. This focus on safety is likely to propel the Automotive Plastic Fuel Tank Market forward, as companies invest in research and development to create products that not only meet regulatory requirements but also exceed consumer expectations.

Stringent Environmental Regulations

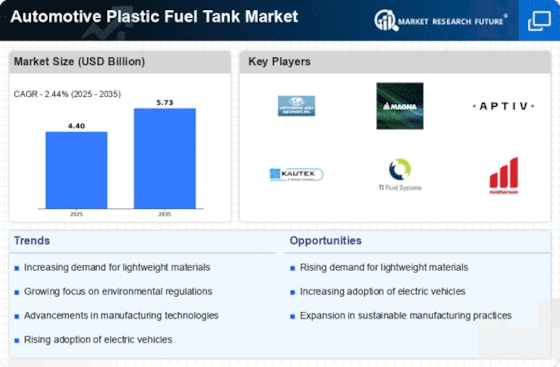

The Automotive Plastic Fuel Tank Market is significantly influenced by stringent environmental regulations aimed at reducing carbon emissions and promoting sustainability. Governments worldwide are implementing policies that encourage the use of eco-friendly materials and manufacturing processes. These regulations often mandate the use of lightweight and recyclable materials in vehicle production, which aligns with the properties of plastic fuel tanks. As a result, manufacturers are increasingly adopting plastic solutions to comply with these regulations while also appealing to environmentally conscious consumers. The market is expected to witness a surge in demand for compliant products, potentially leading to a market growth of approximately 6% over the next few years. This regulatory landscape presents both challenges and opportunities for the Automotive Plastic Fuel Tank Market, as companies navigate compliance while striving for innovation.

Increased Adoption of Electric Vehicles

The Automotive Plastic Fuel Tank Market is poised for transformation due to the rising adoption of electric vehicles (EVs). As the automotive landscape shifts towards electrification, manufacturers are exploring alternative fuel storage solutions, including advanced plastic fuel tanks. While traditional fuel tanks are less relevant in fully electric vehicles, the need for lightweight and durable materials remains critical for hybrid models. The market for plastic fuel tanks is projected to expand as automakers seek to optimize vehicle design and performance. Furthermore, the integration of plastic fuel tanks in hybrid vehicles can enhance overall efficiency, potentially leading to a market growth rate of around 5% annually. This trend indicates a significant opportunity for innovation within the Automotive Plastic Fuel Tank Market, as manufacturers adapt to the evolving needs of the automotive sector.

Rising Demand for Lightweight Materials

The Automotive Plastic Fuel Tank Market is experiencing a notable shift towards lightweight materials, driven by the automotive sector's increasing focus on fuel efficiency and emissions reduction. Plastic fuel tanks, being significantly lighter than their metal counterparts, contribute to overall vehicle weight reduction, which in turn enhances fuel economy. According to recent data, the adoption of plastic fuel tanks has been linked to a potential decrease in vehicle weight by up to 10%. This trend is particularly pronounced in electric and hybrid vehicles, where every kilogram saved can lead to improved range and performance. As manufacturers strive to meet stringent fuel economy standards, the demand for lightweight solutions in the Automotive Plastic Fuel Tank Market is expected to grow, fostering innovation and competition among suppliers.

Technological Innovations in Manufacturing

Technological advancements are playing a pivotal role in shaping the Automotive Plastic Fuel Tank Market. Innovations in manufacturing processes, such as blow molding and injection molding, have enhanced the production efficiency and quality of plastic fuel tanks. These technologies allow for the creation of complex shapes and designs that meet stringent safety and performance standards. Moreover, the introduction of advanced materials, such as high-density polyethylene (HDPE) and nylon, has improved the durability and resistance of plastic tanks to various environmental factors. As a result, manufacturers are likely to see a reduction in production costs and an increase in product lifespan. This technological evolution is expected to drive the Automotive Plastic Fuel Tank Market forward, as companies invest in state-of-the-art facilities to meet the growing demand for high-quality fuel storage solutions.