Increasing Focus on Quality Control

Quality control remains a pivotal aspect of the Back End Production Equipment Market, as manufacturers strive to meet stringent industry standards. The need for reliable testing and inspection equipment is paramount, particularly in sectors such as aerospace and medical devices, where product failure can have dire consequences. In 2025, the quality control equipment market is anticipated to grow, reflecting the heightened emphasis on product reliability. This trend compels manufacturers to invest in advanced back end production equipment that incorporates sophisticated testing and quality assurance features, thereby enhancing overall production quality and safety.

Advancements in Automation and Robotics

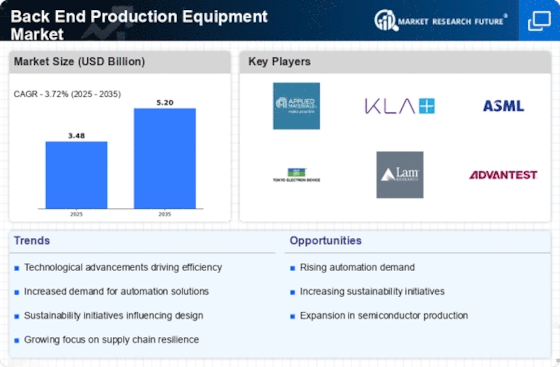

Automation and robotics are transforming the Back End Production Equipment Market, enhancing efficiency and reducing operational costs. The integration of automated systems allows for faster production cycles and improved precision in manufacturing processes. In 2025, the automation market is expected to grow significantly, with investments in robotic systems projected to exceed 200 billion USD. This trend indicates a shift towards smart manufacturing, where back end production equipment is increasingly equipped with advanced robotics. As companies seek to optimize their production lines, the demand for automated back end production equipment is likely to rise, further driving market growth.

Emergence of Smart Manufacturing Solutions

The Back End Production Equipment Market is witnessing a paradigm shift towards smart manufacturing solutions, characterized by the integration of IoT and data analytics. These technologies enable real-time monitoring and predictive maintenance, which can significantly reduce downtime and enhance operational efficiency. By 2025, the smart manufacturing market is projected to reach over 300 billion USD, indicating a strong trend towards digitization in production processes. As manufacturers adopt these solutions, the demand for back end production equipment that can seamlessly integrate with smart technologies is likely to increase, driving innovation and competitiveness in the industry.

Sustainability and Environmental Regulations

Sustainability is becoming increasingly critical in the Back End Production Equipment Market, as manufacturers face mounting pressure to comply with environmental regulations. The push for eco-friendly production processes is prompting companies to invest in energy-efficient and sustainable back end production equipment. In 2025, the market for green technologies in manufacturing is expected to grow substantially, reflecting a broader commitment to sustainability. This trend not only aligns with regulatory requirements but also appeals to environmentally conscious consumers, thereby influencing purchasing decisions. As a result, the demand for sustainable back end production equipment is likely to rise, shaping the future of the industry.

Rising Demand for Semiconductor Manufacturing

The Back End Production Equipment Market is experiencing a surge in demand driven by the increasing need for semiconductor manufacturing. As industries such as automotive, consumer electronics, and telecommunications expand, the requirement for advanced semiconductor devices grows. In 2025, the semiconductor market is projected to reach approximately 600 billion USD, indicating a robust growth trajectory. This demand necessitates sophisticated back end production equipment to ensure efficient packaging, testing, and assembly processes. Consequently, manufacturers are investing in innovative technologies to enhance production capabilities, thereby propelling the Back End Production Equipment Market forward.