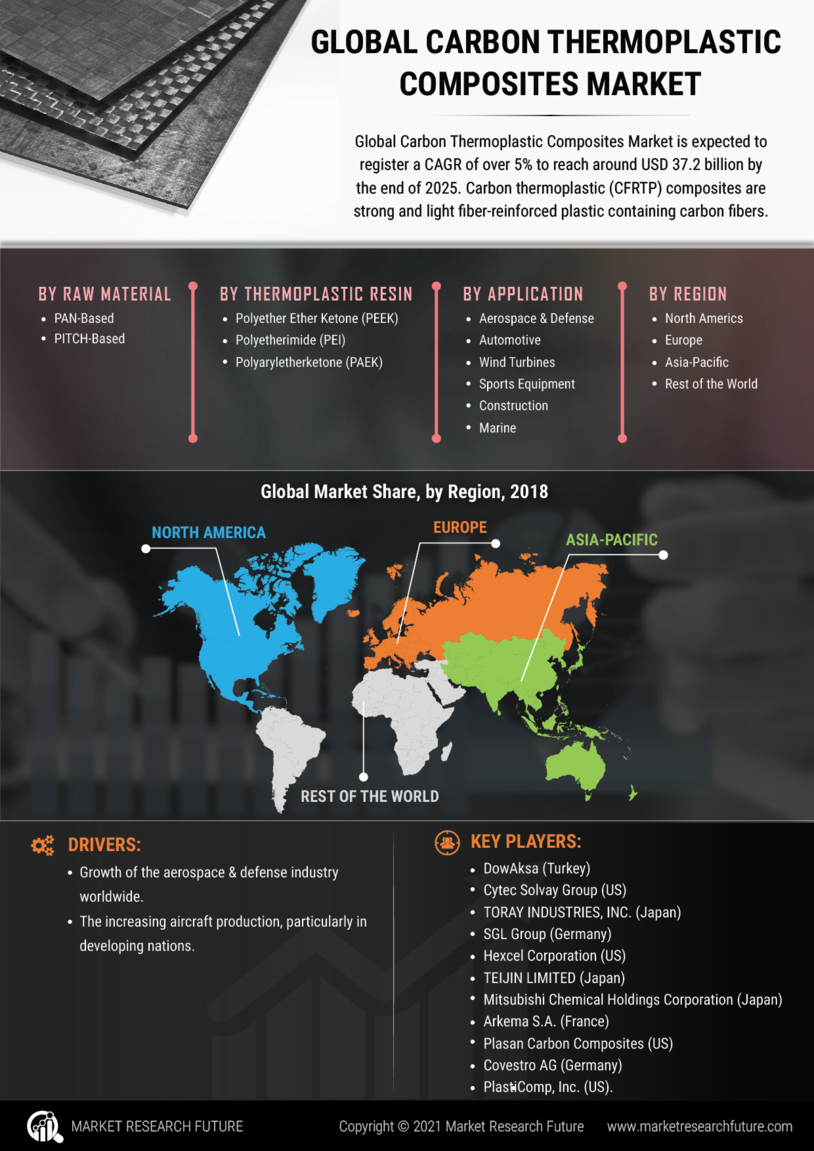

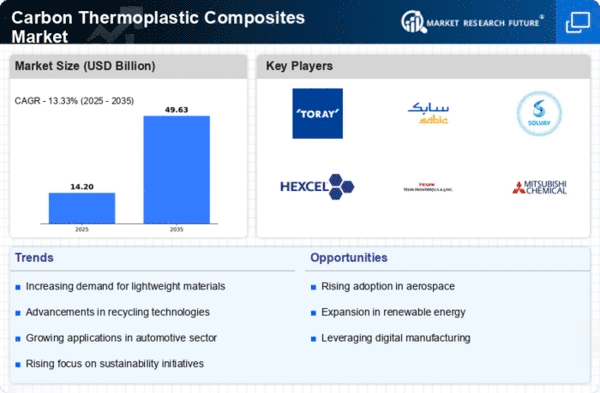

Market Growth Projections

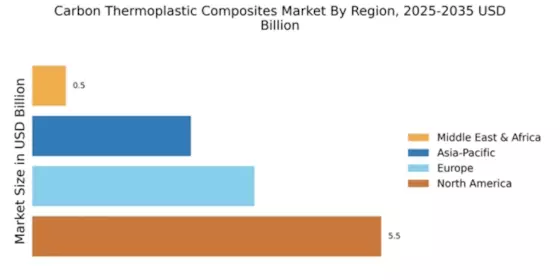

The Global Carbon Thermoplastic Composites Market Industry is poised for substantial growth, with projections indicating a market size of 19.8 USD Billion in 2024 and an anticipated increase to 54.0 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate of 9.54% from 2025 to 2035, highlighting the increasing adoption of carbon thermoplastic composites across various industries. The market's expansion is driven by factors such as technological advancements, rising demand for lightweight materials, and growing applications in renewable energy and aerospace sectors.

Growing Investment in Aerospace Sector

Investment in the aerospace sector is a key driver for the Global Carbon Thermoplastic Composites Market Industry. The aerospace industry increasingly seeks materials that offer high strength-to-weight ratios and excellent fatigue resistance, making carbon thermoplastic composites an attractive option. With the global aerospace market projected to grow substantially, manufacturers are likely to invest in these advanced materials to enhance aircraft performance and reduce operational costs. This trend is expected to contribute to the market's growth, as the industry anticipates reaching 54.0 USD Billion by 2035, reflecting the increasing reliance on innovative materials in aerospace applications.

Rising Demand for Lightweight Materials

The Global Carbon Thermoplastic Composites Market Industry experiences a notable increase in demand for lightweight materials across various sectors, particularly in automotive and aerospace. This shift is driven by the need for enhanced fuel efficiency and reduced emissions. For instance, the automotive sector is increasingly adopting carbon thermoplastic composites to lower vehicle weight, thereby improving fuel economy. As a result, the market is projected to reach 19.8 USD Billion in 2024, reflecting a growing trend towards sustainable manufacturing practices. This demand is likely to propel the industry forward as manufacturers seek innovative solutions to meet regulatory requirements and consumer expectations.

Increasing Applications in Renewable Energy

The Global Carbon Thermoplastic Composites Market Industry is significantly influenced by the increasing applications of composites in renewable energy sectors, particularly in wind energy. The lightweight and high-strength properties of carbon thermoplastic composites make them ideal for manufacturing wind turbine blades, which require materials that can withstand harsh environmental conditions while maintaining structural integrity. As the world shifts towards sustainable energy solutions, the demand for such composites is expected to rise. This trend aligns with the broader global initiative to reduce carbon footprints and promote clean energy technologies, thereby expanding the market's potential.

Technological Advancements in Composite Manufacturing

Technological advancements play a crucial role in the evolution of the Global Carbon Thermoplastic Composites Market Industry. Innovations in processing techniques, such as automated fiber placement and advanced molding technologies, enhance the efficiency and quality of composite production. These advancements not only reduce manufacturing costs but also improve the performance characteristics of the composites, making them more appealing to end-users. As a result, the market is expected to witness a compound annual growth rate of 9.54% from 2025 to 2035. This growth indicates a strong potential for the industry as manufacturers continue to invest in research and development to optimize production processes.

Environmental Regulations and Sustainability Initiatives

The Global Carbon Thermoplastic Composites Market Industry is shaped by stringent environmental regulations and sustainability initiatives that encourage the adoption of eco-friendly materials. Governments worldwide are implementing policies aimed at reducing carbon emissions and promoting sustainable manufacturing practices. This regulatory landscape compels industries to seek alternatives to traditional materials, driving the demand for carbon thermoplastic composites. As companies strive to comply with these regulations, the market is likely to expand, reflecting a broader commitment to sustainability and environmental responsibility across various sectors.