Rising Labor Costs

Rising labor costs are compelling businesses to explore automation solutions, thereby driving the Cartesian Robot Gantry Robot Market. As wages increase in various sectors, companies are seeking cost-effective alternatives to manual labor. Cartesian robots offer a viable solution, providing high levels of accuracy and speed in tasks such as assembly, packaging, and material handling. The potential for these robots to operate continuously without breaks further enhances their appeal. Market analysis suggests that the labor cost increase could lead to a 15% rise in demand for automation technologies, including Cartesian robots, over the next five years. This trend underscores the importance of the Cartesian Robot Gantry Robot Market in addressing the challenges posed by escalating labor expenses.

Growing E-commerce Sector

The expansion of the e-commerce sector is a significant driver for the Cartesian Robot Gantry Robot Market. As online shopping continues to gain popularity, logistics and warehousing operations are under pressure to enhance efficiency and speed. Cartesian robots are increasingly utilized in fulfillment centers for tasks such as sorting, packing, and shipping. The e-commerce market is projected to grow at a rate of 20% annually, which will likely lead to increased investments in automation technologies. This trend suggests that the Cartesian Robot Gantry Robot Market will experience heightened demand as companies strive to meet consumer expectations for rapid delivery and efficient service.

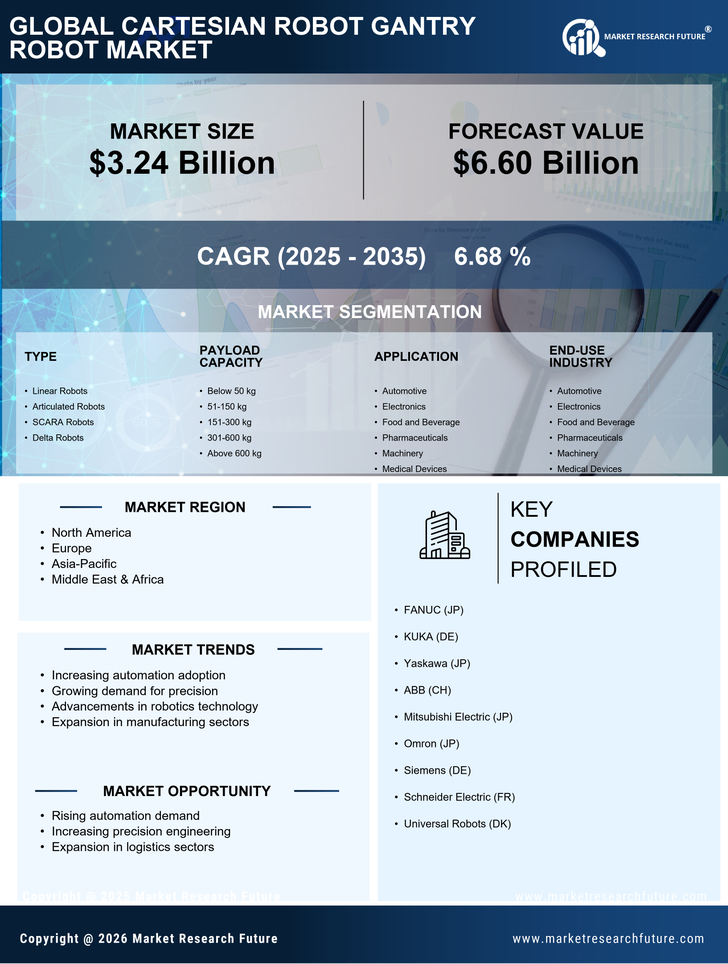

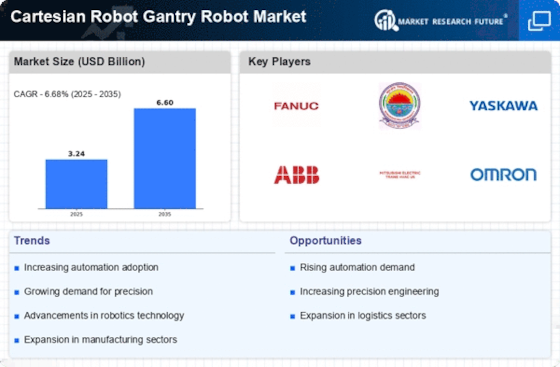

Increased Automation Demand

The demand for automation across various industries is a primary driver for the Cartesian Robot Gantry Robot Market. As companies seek to enhance productivity and reduce labor costs, the adoption of Cartesian robots is on the rise. Industries such as manufacturing, logistics, and pharmaceuticals are increasingly integrating these robots into their operations. According to recent data, the automation market is projected to grow at a compound annual growth rate of over 10% in the coming years. This trend indicates a robust demand for Cartesian robots, which are known for their precision and efficiency. The Cartesian Robot Gantry Robot Market is likely to benefit significantly from this shift towards automation, as businesses prioritize the implementation of advanced robotic solutions to streamline processes and improve overall operational efficiency.

Focus on Precision Manufacturing

The emphasis on precision manufacturing is driving growth in the Cartesian Robot Gantry Robot Market. Industries such as aerospace, automotive, and electronics require high levels of accuracy in their production processes. Cartesian robots are well-suited for these applications due to their ability to perform repetitive tasks with minimal error. The precision manufacturing sector is expected to grow significantly, with estimates suggesting a market size increase of 12% over the next few years. This growth is likely to create further opportunities for the Cartesian Robot Gantry Robot Market, as manufacturers seek reliable robotic solutions to enhance quality control and reduce waste.

Advancements in Robotics Technology

Technological advancements in robotics are significantly influencing the Cartesian Robot Gantry Robot Market. Innovations in artificial intelligence, machine learning, and sensor technology are enhancing the capabilities of Cartesian robots, making them more efficient and versatile. These advancements allow for improved precision in tasks such as pick-and-place operations and complex assembly processes. Furthermore, the integration of IoT technology enables real-time monitoring and data analysis, which can optimize robot performance. The market for robotics is expected to reach USD 200 billion by 2025, indicating a strong growth trajectory. This growth is likely to propel the Cartesian Robot Gantry Robot Market forward, as companies increasingly adopt cutting-edge robotic solutions to remain competitive.