Rising Labor Costs

Labor costs have been on the rise in various regions, prompting companies to seek cost-effective solutions to maintain profitability. The Gantry Industrial Robots Market is poised to benefit from this trend, as businesses increasingly turn to automation to mitigate labor expenses. With labor costs projected to increase by an average of 3% annually, organizations are compelled to invest in technologies that can reduce reliance on human labor. Gantry robots, known for their efficiency in performing tasks such as material handling and assembly, present a viable alternative. By automating these processes, companies can not only save on labor costs but also enhance operational efficiency. This shift towards automation in response to rising labor costs is likely to drive growth in the Gantry Industrial Robots Market, as more businesses recognize the long-term financial benefits of investing in robotic solutions.

Growing E-commerce Sector

The rapid expansion of the e-commerce sector is creating new opportunities for the Gantry Industrial Robots Market. As online shopping continues to gain traction, logistics and warehousing operations are under pressure to optimize their processes to meet increasing consumer demands. The e-commerce market is projected to grow by over 20% annually, necessitating efficient order fulfillment and inventory management solutions. Gantry robots are particularly well-suited for these tasks, as they can automate the movement of goods within warehouses, thereby improving speed and accuracy. This trend towards automation in the e-commerce sector is likely to drive demand for gantry robots, as companies seek to enhance their operational efficiency and reduce delivery times. The growing e-commerce landscape presents a significant growth opportunity for the Gantry Industrial Robots Market.

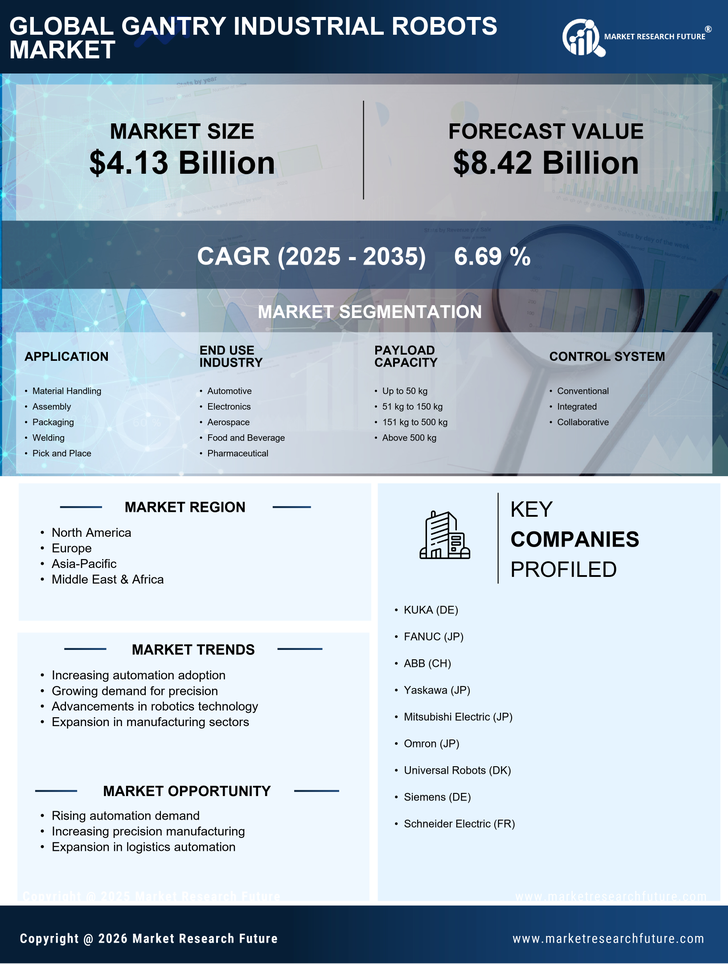

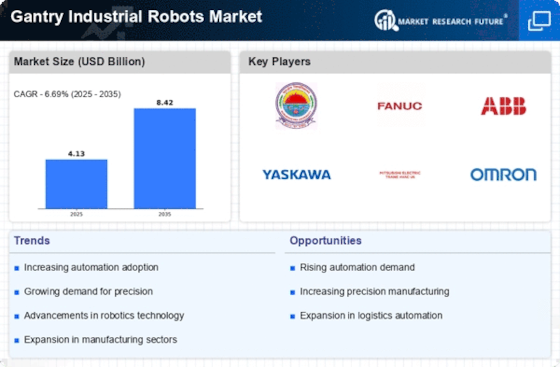

Increased Automation Demand

The Gantry Industrial Robots Market is experiencing a surge in demand for automation across various sectors. Industries such as manufacturing, logistics, and construction are increasingly adopting automation to enhance efficiency and reduce operational costs. According to recent data, the automation market is projected to grow at a compound annual growth rate of approximately 10% over the next five years. This trend is driven by the need for precision, speed, and reliability in production processes. As companies strive to remain competitive, the integration of gantry robots into their operations appears to be a strategic move. These robots offer the ability to handle heavy loads and perform repetitive tasks with minimal human intervention, thereby streamlining workflows and improving productivity. Consequently, the growing emphasis on automation is likely to propel the Gantry Industrial Robots Market forward.

Focus on Safety and Ergonomics

Safety and ergonomics are becoming increasingly important considerations in industrial operations, influencing the Gantry Industrial Robots Market. As companies strive to create safer work environments, the adoption of gantry robots is seen as a proactive measure to reduce workplace injuries. These robots can perform hazardous tasks, thereby minimizing the risk to human workers. Furthermore, the ergonomic design of gantry robots allows for efficient handling of heavy materials, reducing the physical strain on employees. With workplace safety regulations becoming more stringent, organizations are likely to invest in automation solutions that enhance safety and ergonomics. This focus on creating safer work environments is expected to drive growth in the Gantry Industrial Robots Market, as more companies recognize the benefits of integrating robotic solutions into their operations.

Advancements in Robotics Technology

Technological advancements in robotics are significantly influencing the Gantry Industrial Robots Market. Innovations in artificial intelligence, machine learning, and sensor technology are enhancing the capabilities of gantry robots, making them more versatile and efficient. For instance, the integration of AI allows these robots to learn from their environment and adapt to various tasks, thereby increasing their utility across different applications. The market for robotics technology is expected to reach USD 200 billion by 2026, indicating a robust growth trajectory. As these technologies continue to evolve, the functionality and performance of gantry robots are likely to improve, attracting more industries to adopt them. This ongoing evolution in robotics technology is a key driver for the Gantry Industrial Robots Market, as it opens new avenues for application and enhances the overall value proposition of robotic solutions.