Growing Focus on Sustainability

The Gantry Robot Market is increasingly aligning with the global emphasis on sustainability and environmentally friendly practices. Companies are recognizing the importance of reducing waste and energy consumption in their operations. Gantry robots contribute to these sustainability goals by optimizing resource utilization and minimizing material waste during manufacturing processes. Recent studies suggest that automation can lead to a reduction in energy consumption by up to 20% in manufacturing settings. As organizations strive to meet regulatory requirements and consumer expectations regarding sustainability, the adoption of gantry robots is likely to become more prevalent. This shift not only enhances operational efficiency but also positions companies favorably in a market that values sustainable practices, thereby driving growth in the gantry robot market.

Expansion of E-commerce and Logistics

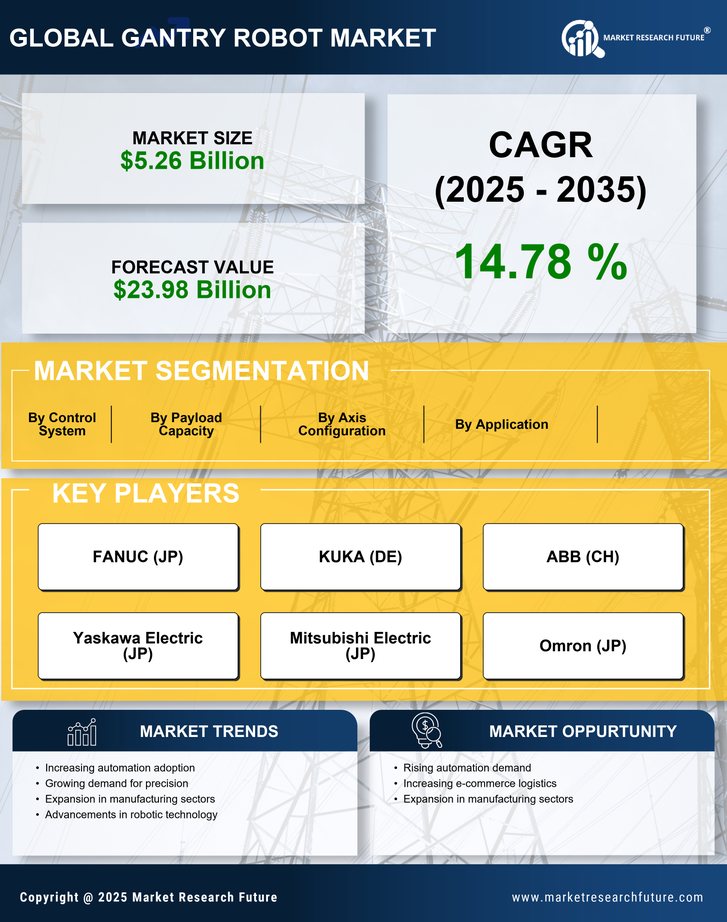

The Gantry Robot Market is significantly influenced by the rapid expansion of e-commerce and logistics sectors. With the increasing volume of online orders, companies are seeking efficient solutions to streamline their warehousing and distribution processes. Gantry robots are being deployed for tasks such as order picking, packing, and palletizing, which enhances operational efficiency and reduces labor costs. Recent statistics indicate that the e-commerce sector is expected to grow by over 15% annually, creating a substantial demand for automation solutions. This trend suggests that gantry robots will play a crucial role in optimizing supply chain operations, thereby driving growth in the gantry robot market. As logistics companies aim to improve delivery times and reduce operational bottlenecks, the adoption of gantry robots is likely to become a standard practice in the industry.

Technological Advancements in Robotics

The Gantry Robot Market is witnessing a wave of technological advancements that are reshaping the landscape of automation. Innovations such as artificial intelligence, machine learning, and advanced sensors are enhancing the capabilities of gantry robots, making them more versatile and efficient. These technologies enable robots to perform complex tasks with greater accuracy and adaptability, which is essential in dynamic manufacturing environments. The integration of smart technologies is projected to increase the efficiency of gantry robots by up to 30%, according to industry estimates. As manufacturers seek to leverage these advancements to improve productivity and reduce operational costs, the demand for technologically advanced gantry robots is expected to rise. This trend indicates a shift towards more intelligent automation solutions within the gantry robot market.

Rising Demand for Precision Manufacturing

The Gantry Robot Market is experiencing a notable surge in demand for precision manufacturing solutions. Industries such as automotive, electronics, and aerospace are increasingly adopting gantry robots to enhance accuracy and efficiency in production processes. The need for high-quality products with minimal defects drives manufacturers to invest in advanced automation technologies. According to recent data, the precision manufacturing sector is projected to grow at a compound annual growth rate of approximately 7.5% over the next five years. This growth is likely to propel the adoption of gantry robots, as they offer superior precision in tasks such as assembly, welding, and material handling. As companies strive to meet stringent quality standards, the integration of gantry robots into manufacturing lines appears to be a strategic move to maintain competitiveness in the market.

Increased Investment in Research and Development

The Gantry Robot Market is benefiting from increased investment in research and development (R&D) across various sectors. Companies are allocating significant resources to innovate and improve automation technologies, including gantry robots. This focus on R&D is essential for developing next-generation robots that can meet the evolving demands of industries such as manufacturing, healthcare, and logistics. Recent data indicates that R&D spending in the automation sector is projected to grow by approximately 10% annually. This investment is likely to lead to breakthroughs in robot design, functionality, and efficiency, further driving the adoption of gantry robots. As organizations seek to enhance their competitive edge through innovation, the emphasis on R&D will play a pivotal role in shaping the future of the gantry robot market.