Increasing Demand for Oil and Gas

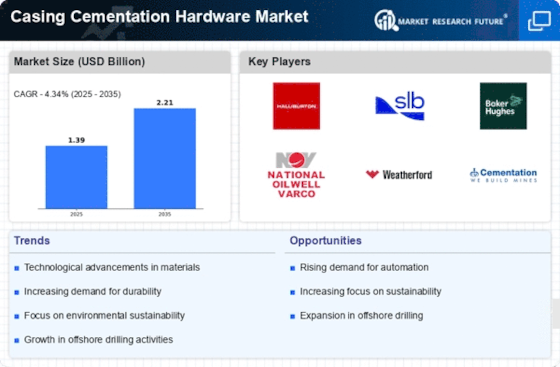

The Casing Cementation Hardware Market is experiencing a surge in demand driven by the increasing global consumption of oil and gas. As economies expand, the need for energy resources escalates, prompting exploration and production activities. This trend is reflected in the rising number of drilling projects, which necessitate robust casing cementation solutions to ensure well integrity and safety. According to recent data, the oil and gas sector is projected to grow at a compound annual growth rate of approximately 3.5% over the next few years, further fueling the demand for advanced casing cementation hardware. Consequently, manufacturers are focusing on developing innovative products that meet the evolving needs of the industry, thereby enhancing their market presence.

Expansion of Offshore Drilling Activities

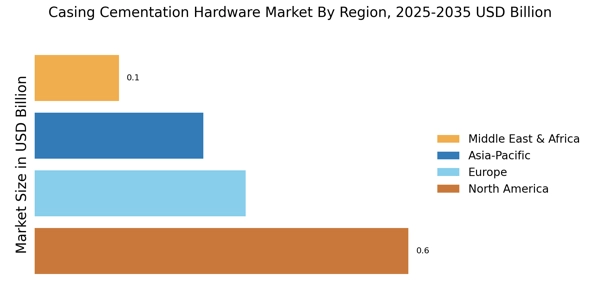

The expansion of offshore drilling activities significantly influences the Casing Cementation Hardware Market. As oil and gas reserves become increasingly difficult to access onshore, companies are turning to offshore sites, which often require specialized cementation solutions to address unique challenges such as high pressure and corrosive environments. The offshore drilling market is anticipated to grow, with investments in new technologies and equipment to enhance operational efficiency. This shift is likely to drive demand for advanced casing cementation hardware that can withstand harsh conditions and ensure the integrity of offshore wells. Consequently, manufacturers are adapting their product offerings to cater to the specific needs of offshore operations.

Rising Focus on Well Integrity and Safety

The emphasis on well integrity and safety is a critical driver for the Casing Cementation Hardware Market. With the increasing scrutiny on environmental impacts and safety regulations, operators are prioritizing the use of high-quality cementation hardware to prevent leaks and ensure the longevity of wells. This focus is underscored by regulatory bodies mandating stringent safety standards, which compel companies to adopt superior cementation practices. The market for casing cementation hardware is projected to witness growth as operators seek reliable solutions that enhance well performance and mitigate risks associated with wellbore instability. This trend indicates a shift towards more responsible and sustainable practices within the industry.

Growing Investment in Renewable Energy Projects

The growing investment in renewable energy projects is emerging as a noteworthy driver for the Casing Cementation Hardware Market. As the energy landscape evolves, there is an increasing need for hybrid solutions that integrate traditional oil and gas operations with renewable energy initiatives. This trend is prompting companies to explore innovative cementation technologies that can support both sectors. The transition towards cleaner energy sources may lead to new applications for casing cementation hardware, particularly in geothermal energy projects, where effective cementing is crucial for well performance. This diversification could open new avenues for growth within the casing cementation hardware market.

Technological Innovations in Cementation Techniques

Technological advancements play a pivotal role in shaping the Casing Cementation Hardware Market. Innovations in cementation techniques, such as the development of smart cement and advanced monitoring systems, are enhancing the efficiency and effectiveness of cementing operations. These technologies not only improve the quality of cement bonds but also reduce the risk of well failures. The integration of automation and real-time data analytics into cementation processes is expected to streamline operations and minimize costs. As a result, companies are increasingly investing in research and development to leverage these technologies, which could lead to a more competitive landscape in the casing cementation hardware sector.