Growing Industrial Applications

The Catalytic Bead Sensor Market is witnessing a surge in industrial applications, particularly in sectors such as petrochemicals, pharmaceuticals, and food processing. These industries require precise gas detection to ensure safety and compliance with health regulations. The increasing complexity of industrial processes necessitates the use of reliable detection systems, which catalytic bead sensors provide. Market analysis indicates that the demand for these sensors in industrial applications could grow by 20% in the coming years, driven by the need for enhanced safety measures and operational efficiency. As industries continue to evolve, the role of catalytic bead sensors in monitoring and controlling gas emissions becomes increasingly vital.

Increased Focus on Workplace Safety

The Catalytic Bead Sensor Market is significantly influenced by the growing emphasis on workplace safety across various sectors. Organizations are increasingly prioritizing the health and safety of their employees, leading to the adoption of advanced gas detection technologies. Catalytic bead sensors are essential tools in this regard, as they provide real-time monitoring of hazardous gases, thereby reducing the risk of accidents. The market is projected to expand as companies invest in safety measures to comply with occupational health standards. This trend is likely to result in a market growth rate of approximately 8% annually, reflecting the critical importance of ensuring safe working environments in industries such as construction, manufacturing, and mining.

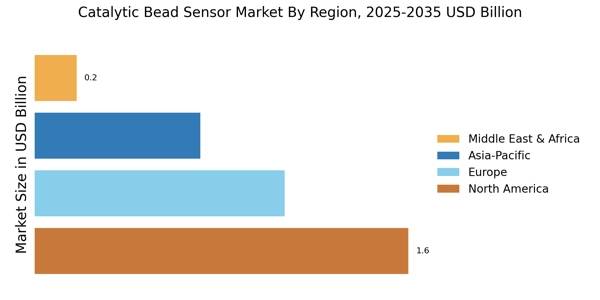

Emerging Markets and Economic Development

The Catalytic Bead Sensor Market is poised for growth in emerging markets, where rapid industrialization and economic development are driving the demand for gas detection solutions. Countries in Asia-Pacific and Latin America are witnessing an increase in manufacturing activities, leading to a heightened need for effective safety measures. The market in these regions is expected to grow at a rate of 10% annually, as businesses seek to implement reliable gas detection systems to comply with international safety standards. This expansion presents opportunities for manufacturers to introduce innovative catalytic bead sensors tailored to the specific needs of these developing economies, thereby enhancing market penetration and fostering economic growth.

Technological Innovations in Sensor Design

Technological advancements are significantly influencing the Catalytic Bead Sensor Market, as manufacturers are investing in research and development to enhance sensor performance and reliability. Innovations such as miniaturization, improved sensitivity, and faster response times are becoming increasingly prevalent. For instance, the integration of advanced materials and smart technologies is enabling the development of sensors that can operate effectively in harsh environments. The market is expected to witness a surge in the adoption of these advanced sensors, with estimates suggesting a potential increase in market size by 15% over the next few years. This evolution in sensor design not only improves detection capabilities but also expands the application range of catalytic bead sensors across various industries.

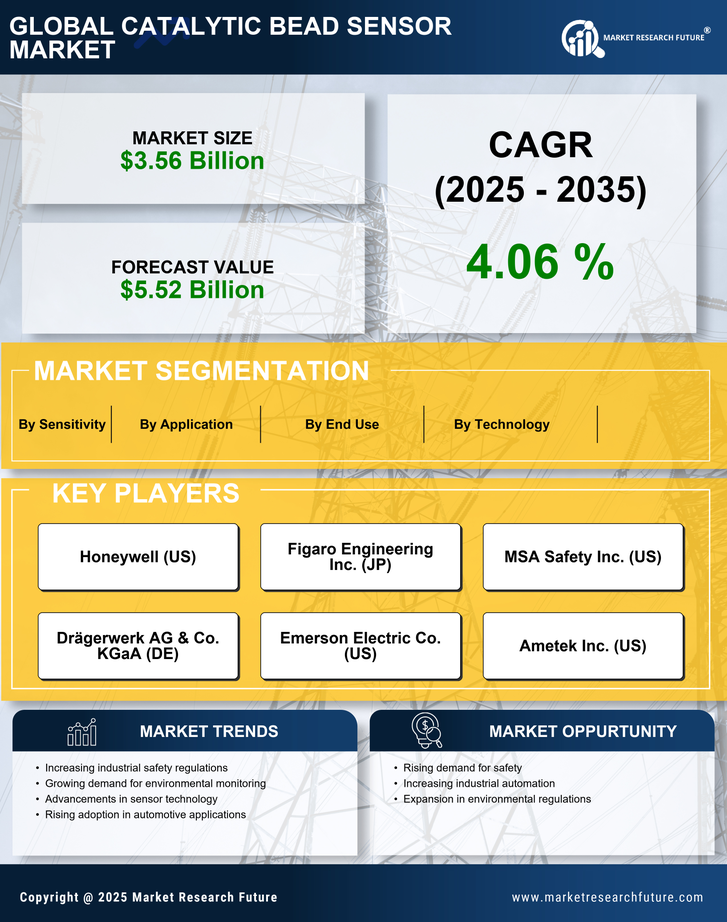

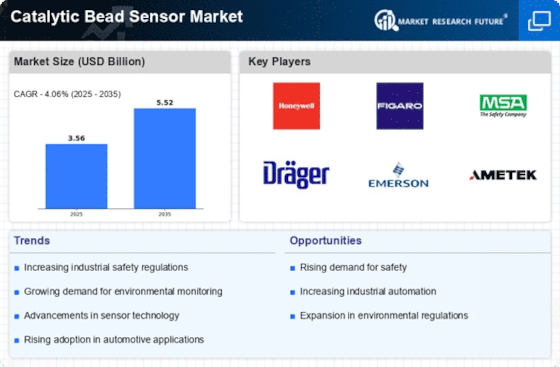

Rising Demand for Safety and Environmental Monitoring

The Catalytic Bead Sensor Market is experiencing a notable increase in demand driven by heightened awareness regarding safety and environmental monitoring. Industries such as oil and gas, chemical manufacturing, and waste management are increasingly adopting catalytic bead sensors to detect flammable gases and ensure compliance with safety regulations. The market is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years, reflecting the critical role these sensors play in safeguarding personnel and the environment. As regulatory bodies enforce stricter guidelines, the adoption of catalytic bead sensors becomes essential for companies aiming to mitigate risks associated with gas leaks and emissions. This trend underscores the importance of reliable detection technologies in maintaining operational safety and environmental integrity.