Sustainability Trends in Packaging

Sustainability trends are reshaping the Caustic Soda Packaging Market as consumers and businesses alike prioritize eco-friendly solutions. The demand for sustainable packaging materials, such as biodegradable plastics and recyclable options, is on the rise. This shift is partly driven by increasing awareness of environmental issues and the need for companies to reduce their carbon footprint. As a result, manufacturers are exploring alternative materials that can effectively package caustic soda while minimizing environmental impact. The market for sustainable packaging is expected to grow, potentially reaching a valuation of several billion dollars in the coming years, thereby influencing the overall dynamics of the caustic soda packaging sector.

Rising Demand from End-User Industries

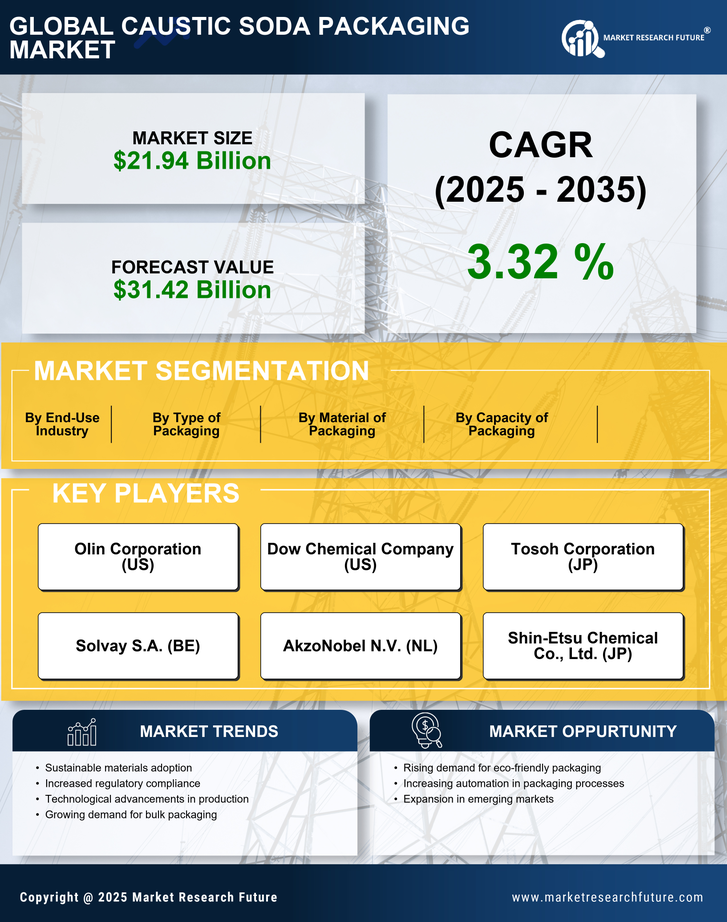

The Caustic Soda Packaging Market experiences a notable surge in demand driven by various end-user sectors, including chemicals, textiles, and food processing. As industries expand, the need for effective packaging solutions to ensure the safe transport and storage of caustic soda becomes increasingly critical. For instance, the chemical sector, which accounts for a substantial portion of caustic soda consumption, is projected to grow at a compound annual growth rate of approximately 4.5% over the next few years. This growth necessitates innovative packaging solutions that can withstand the corrosive nature of caustic soda, thereby propelling advancements in the packaging market.

Technological Innovations in Packaging

Technological innovations play a pivotal role in the evolution of the Caustic Soda Packaging Market. Advancements in materials science and packaging technology have led to the development of more durable and efficient packaging solutions. Innovations such as smart packaging, which incorporates sensors to monitor the condition of the product, are gaining traction. These technologies not only enhance the safety and integrity of caustic soda during transport but also provide valuable data to manufacturers and consumers. As the industry continues to embrace these technological advancements, the packaging solutions are likely to become more sophisticated, catering to the specific needs of caustic soda handling.

Regulatory Compliance and Safety Standards

The Caustic Soda Packaging Market is significantly influenced by stringent regulatory compliance and safety standards imposed by various governmental bodies. These regulations are designed to ensure the safe handling and transportation of hazardous materials, including caustic soda. Compliance with these standards often requires the adoption of specialized packaging materials that can mitigate risks associated with leaks and spills. As a result, manufacturers are increasingly investing in research and development to create packaging solutions that not only meet regulatory requirements but also enhance safety during storage and transport. This trend is likely to drive innovation within the packaging sector.

Growth of E-commerce and Online Distribution Channels

The growth of e-commerce and online distribution channels is significantly impacting the Caustic Soda Packaging Market. As more businesses transition to online platforms for purchasing chemicals, the demand for efficient and secure packaging solutions has intensified. E-commerce requires packaging that not only protects the product during transit but also complies with safety regulations. This shift is prompting manufacturers to innovate and adapt their packaging strategies to meet the unique challenges posed by online sales. The e-commerce sector is expected to continue expanding, which may further drive the demand for specialized caustic soda packaging solutions.