Technological Innovations

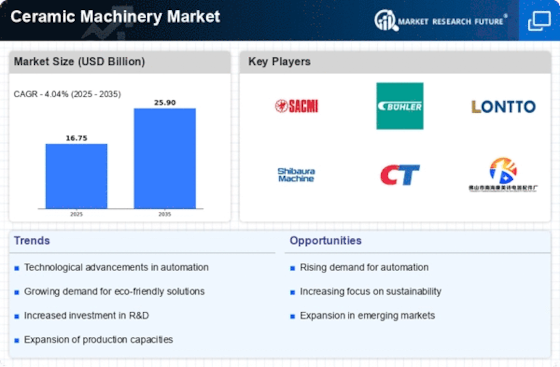

Technological advancements play a pivotal role in shaping the Ceramic Machinery Market. The introduction of cutting-edge technologies, such as 3D printing and automation, is revolutionizing production processes. In recent years, the market has witnessed a shift towards more efficient and precise machinery, which enhances product quality and reduces waste. For instance, the adoption of Industry 4.0 principles is enabling manufacturers to optimize their operations through data analytics and machine learning. This trend is expected to continue, with investments in research and development projected to increase by 10% annually. As a result, companies that leverage these innovations are likely to gain a competitive edge, driving the overall growth of the ceramic machinery market.

Rising Construction Activities

The Ceramic Machinery Market is experiencing a notable surge due to increasing construction activities across various sectors. As urbanization accelerates, the demand for ceramic tiles and sanitary ware rises, driving the need for advanced machinery. In 2025, the construction sector is projected to grow at a compound annual growth rate of approximately 5.5%, which directly influences the ceramic machinery market. This growth is attributed to infrastructure development, residential projects, and commercial buildings, all of which require high-quality ceramic products. Consequently, manufacturers are investing in innovative machinery to enhance production efficiency and meet the escalating demand. The integration of automation and smart technologies in ceramic machinery is likely to further streamline operations, thereby positioning the industry for sustained growth.

Expansion of the Automotive Sector

The Ceramic Machinery Market is also benefiting from the expansion of the automotive sector, particularly in the production of ceramic components. As the automotive industry increasingly incorporates ceramic materials for applications such as brake pads and engine components, the demand for specialized ceramic machinery is on the rise. In 2025, the automotive ceramics market is projected to grow at a rate of 7%, which will subsequently drive the need for advanced machinery capable of producing high-performance ceramic parts. This trend indicates a diversification of the ceramic machinery market, as manufacturers seek to cater to the specific needs of the automotive sector. The integration of advanced technologies in machinery is likely to enhance production capabilities, ensuring that manufacturers can meet the evolving demands of the automotive industry.

Increased Investment in Infrastructure

The Ceramic Machinery Market is poised for growth due to increased investment in infrastructure projects worldwide. Governments and private entities are allocating substantial funds towards the development of roads, bridges, and public facilities, which in turn drives the demand for ceramic materials. In 2025, infrastructure spending is expected to reach unprecedented levels, with a projected increase of 8% compared to previous years. This surge in investment creates a favorable environment for the ceramic machinery market, as manufacturers strive to meet the heightened demand for tiles and other ceramic products used in construction. The focus on durable and aesthetically pleasing materials further propels the need for advanced ceramic machinery, ensuring that the industry remains robust and competitive.

Growing Demand for Eco-Friendly Products

The Ceramic Machinery Market is increasingly influenced by the rising consumer preference for eco-friendly products. As environmental awareness grows, manufacturers are compelled to adopt sustainable practices in their production processes. This shift is evident in the development of energy-efficient machinery and the use of recycled materials in ceramic production. In 2025, it is estimated that the market for eco-friendly ceramic products will expand by 15%, reflecting a broader trend towards sustainability. Consequently, machinery that supports these initiatives is in high demand, prompting manufacturers to innovate and adapt. The emphasis on reducing carbon footprints and minimizing waste is likely to shape the future of the ceramic machinery market, aligning with global sustainability goals.

Leave a Comment