Increasing Industrial Automation

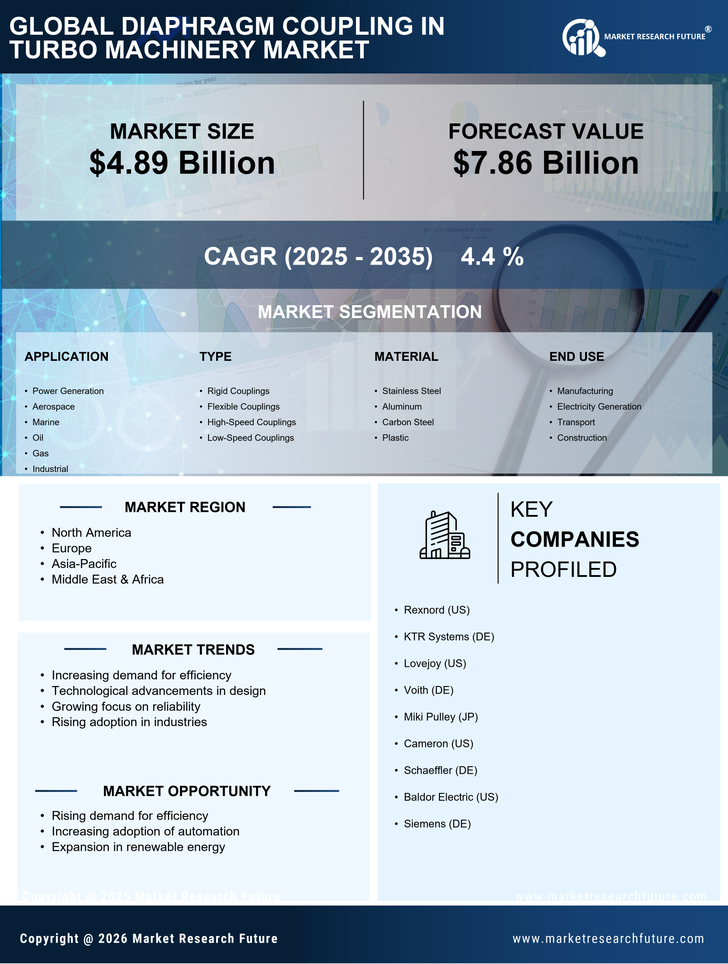

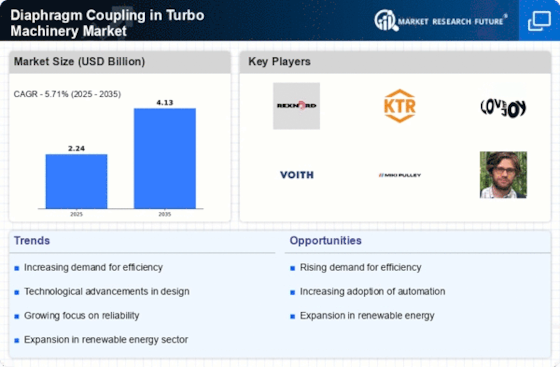

The trend towards industrial automation is a significant driver for the Diaphragm Coupling in Turbo Machinery Market. As industries adopt automated systems to enhance productivity and reduce labor costs, the need for reliable and efficient coupling solutions becomes paramount. Diaphragm couplings are well-suited for automated machinery, providing the necessary flexibility and reliability in power transmission. The automation market is projected to grow, with diaphragm couplings playing a crucial role in ensuring seamless operation of automated systems. This shift towards automation not only boosts the demand for diaphragm couplings but also encourages innovation in their design and application.

Growth in Renewable Energy Sector

The expansion of the renewable energy sector significantly influences the Diaphragm Coupling in Turbo Machinery Market. As countries invest in wind, solar, and hydroelectric power, the demand for reliable and efficient machinery increases. Diaphragm couplings are essential in wind turbines and hydroelectric generators, where they facilitate the transfer of power while compensating for misalignment. The renewable energy market is expected to witness substantial growth, with diaphragm couplings being integral to the performance and reliability of these systems. This trend indicates a robust future for diaphragm couplings as the world shifts towards sustainable energy solutions.

Rising Demand for Energy Efficiency

The increasing emphasis on energy efficiency in industrial applications drives the Diaphragm Coupling in Turbo Machinery Market. As industries seek to reduce operational costs and minimize energy consumption, diaphragm couplings offer a solution by providing high torque transmission with minimal energy loss. This efficiency is particularly crucial in turbo machinery, where performance optimization is paramount. According to recent data, the energy efficiency market is projected to grow significantly, with diaphragm couplings playing a vital role in achieving these goals. The ability of diaphragm couplings to accommodate misalignment while maintaining efficiency further enhances their appeal in energy-intensive sectors.

Expansion of Aerospace and Defense Sectors

The aerospace and defense sectors are experiencing significant growth, which positively impacts the Diaphragm Coupling in Turbo Machinery Market. As these sectors require high-performance machinery for various applications, the demand for diaphragm couplings is likely to increase. Diaphragm couplings are essential in aircraft engines and defense systems, where reliability and efficiency are critical. The aerospace market is projected to expand, driven by advancements in technology and increasing defense budgets. This growth presents opportunities for diaphragm coupling manufacturers to cater to the specific needs of these industries, thereby enhancing their market presence.

Technological Innovations in Manufacturing

Technological advancements in manufacturing processes are reshaping the Diaphragm Coupling in Turbo Machinery Market. Innovations such as 3D printing and advanced materials are enhancing the design and production of diaphragm couplings, leading to improved performance and durability. These advancements allow for the creation of couplings that can withstand higher loads and operate in more demanding environments. As manufacturers adopt these technologies, the market for diaphragm couplings is likely to expand, driven by the need for high-performance components in turbo machinery applications. The integration of smart technologies further enhances the functionality of diaphragm couplings, making them more attractive to end-users.