Circulating Fluid Bed Boilers Size

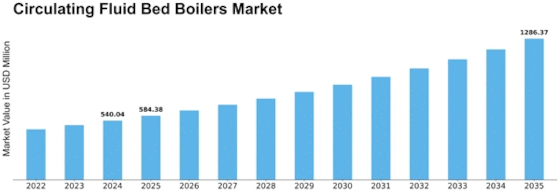

Circulating Fluid Bed Boilers Market Growth Projections and Opportunities

Several key factors have influenced the dynamics of CFB boilers; as a result, the market has experienced some noticeable changes. These boilers are widely used due to their ability to burn different types of fuels while emitting less waste gas and therefore are in high demand across the sectors such as power generation and manufacturing. One of the primary drivers shaping the market dynamics of CFB boilers is the growing emphasis on environmental sustainability. Industries are turning to cleaner and more efficient energy solutions due to stringent regulations aimed at reducing carbon emissions. The reason behind this is that CFB boilers possess the ability to effectively control sulfur dioxide, nitrogen oxides, and particulate matter emissions which aligns with stringent global environmental norms.

Moreover, regarding market dynamics, versatility plays a significant role for CFB boilers. The range of materials that can be burned in these plants efficiently varies from coal and biomass to various rubbish types. This flexibility matches up with differences in fuel availability as well as fluctuations in costs, making them adjustable tools by which industries can optimize operational activities in accordance with fuel availability and cost-effectiveness.

In addition, there has been a significant contribution from changing characteristics in energy sector activities towards market dynamics for CFB boilers. This has seen an increase both in electricity demand and need for reliable power generation which have fueled adoption of CFB technology. They also serve as an option for producing electricity using a wider array of fuels within our current energy mix hence promoting their market growth.

Further still, geographical aspects and regional policies greatly influence how the markets behave for CFB boilers. In countries where mining resources such as coal or biomass is readily available many industries have embraced these because they are cheap thereby enhancing their level of adoption compared to those in other regions.

Leave a Comment