Increased Focus on Hygiene and Safety

In the Cling Wrap Machine Market, there is an escalating emphasis on hygiene and safety standards, particularly in food handling and packaging. The heightened awareness surrounding food safety has led to a greater reliance on cling wrap machines that ensure products are sealed securely and protected from contamination. Regulatory bodies have implemented stricter guidelines, compelling manufacturers to adopt advanced cling wrap technologies that comply with safety standards. This trend is likely to drive innovation within the industry, as companies seek to develop machines that not only enhance safety but also improve operational efficiency. The integration of smart technologies in cling wrap machines may further bolster this market segment.

Technological Innovations in Packaging

Technological advancements are playing a pivotal role in shaping the Cling Wrap Machine Market. Innovations such as automated cling wrap machines and those equipped with smart features are becoming increasingly prevalent. These machines not only enhance productivity but also reduce labor costs, making them attractive to manufacturers. The integration of artificial intelligence and machine learning in packaging processes is expected to optimize operations and improve product quality. As companies strive to remain competitive, the adoption of these advanced technologies is likely to accelerate, driving growth in the cling wrap machine market. The potential for customization and flexibility in packaging solutions may also appeal to a broader range of industries.

Expansion of the Food and Beverage Sector

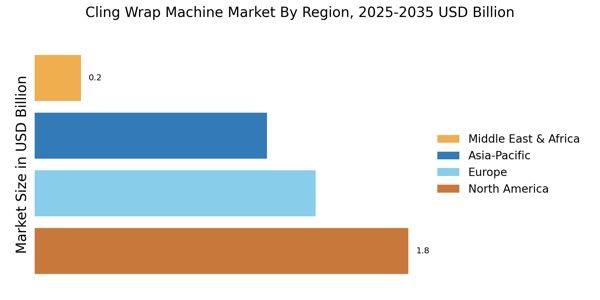

The Cling Wrap Machine Market is significantly influenced by the expansion of the food and beverage sector. As new restaurants, cafes, and food processing units emerge, the demand for cling wrap machines is expected to rise correspondingly. The food and beverage industry has been projected to grow at a rate of around 5% annually, which could lead to increased investments in packaging technologies. This expansion necessitates efficient packaging solutions that cling wrap machines provide, ensuring that food products remain fresh and appealing to consumers. Furthermore, the trend towards ready-to-eat meals and meal kits is likely to further enhance the demand for cling wrap machines, as these products require effective packaging to maintain quality.

Rising Demand for Food Packaging Solutions

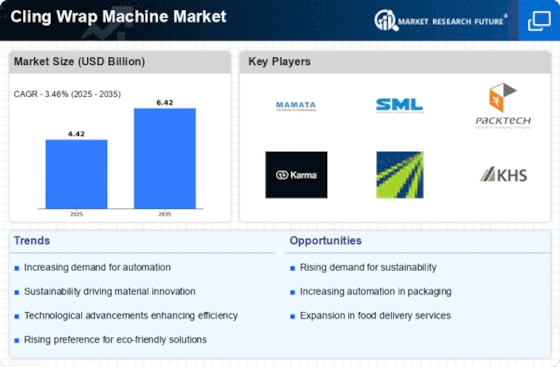

The Cling Wrap Machine Market is experiencing a notable surge in demand for efficient food packaging solutions. As consumer preferences shift towards convenience and freshness, cling wrap machines are increasingly utilized in both commercial and residential settings. The market for food packaging is projected to grow at a compound annual growth rate of approximately 4.5%, indicating a robust opportunity for cling wrap machine manufacturers. This growth is driven by the need for products that extend shelf life and maintain food quality. Additionally, the rise in takeout and delivery services has further amplified the demand for effective packaging solutions, positioning cling wrap machines as essential tools in the food industry.

Growing Environmental Concerns and Sustainable Practices

The Cling Wrap Machine Market is witnessing a shift towards sustainable practices, driven by growing environmental concerns. Consumers and businesses alike are increasingly prioritizing eco-friendly packaging solutions. This trend has prompted manufacturers to explore biodegradable and recyclable cling wrap materials, which could reshape the market landscape. The demand for sustainable packaging is projected to increase, with a significant portion of consumers willing to pay a premium for environmentally friendly products. As a result, cling wrap machine manufacturers are likely to invest in research and development to create machines that can handle these new materials effectively. This shift towards sustainability may not only enhance brand reputation but also align with regulatory pressures for reduced plastic usage.

.png)