Expansion of End-User Industries

The Cold Gas Spray Coating Market is benefiting from the expansion of end-user industries, particularly in sectors such as oil and gas, marine, and electronics. As these industries continue to grow, the demand for advanced coating solutions that enhance performance and protect against corrosion is likely to increase. For instance, the oil and gas sector is increasingly adopting cold gas spray coatings for pipeline repairs and maintenance, which can significantly extend the lifespan of critical infrastructure. Additionally, the electronics industry is exploring cold gas spray technology for the production of high-performance components. Market data indicates that the end-user industries segment is expected to contribute to a 20% increase in market revenue by 2026. This expansion highlights the versatility and applicability of cold gas spray technology across diverse sectors, further solidifying its position in the Cold Gas Spray Coating Market.

Rising Adoption in Aerospace Applications

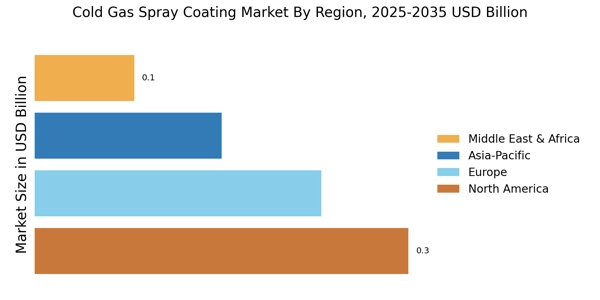

The Cold Gas Spray Coating Market is witnessing a significant uptick in the adoption of cold gas spray technology within the aerospace sector. This trend is largely attributed to the stringent requirements for lightweight and high-strength materials in aircraft manufacturing and maintenance. Cold gas spray coatings offer a unique advantage by enabling the repair and enhancement of critical components without compromising their structural integrity. Industry data suggests that the aerospace segment is expected to account for over 30% of the total market share by 2026. This shift towards cold gas spray technology not only enhances the performance of aerospace components but also aligns with the industry's commitment to sustainability and efficiency. As a result, the Cold Gas Spray Coating Market is likely to see continued growth driven by these aerospace applications.

Growing Focus on Environmental Sustainability

The Cold Gas Spray Coating Market is increasingly influenced by a growing focus on environmental sustainability. As industries strive to reduce their carbon footprint and minimize waste, cold gas spray technology presents a viable solution. Unlike traditional coating methods, cold gas spray processes generate minimal waste and do not require harmful solvents, making them more environmentally friendly. This shift towards sustainable practices is particularly evident in sectors such as automotive and energy, where companies are actively seeking eco-friendly alternatives. Market projections suggest that the demand for environmentally sustainable coatings will drive a significant portion of the growth in the Cold Gas Spray Coating Market, potentially increasing market size by 15% over the next five years. This trend reflects a broader commitment to sustainability across various industries.

Increasing Demand for Wear-Resistant Coatings

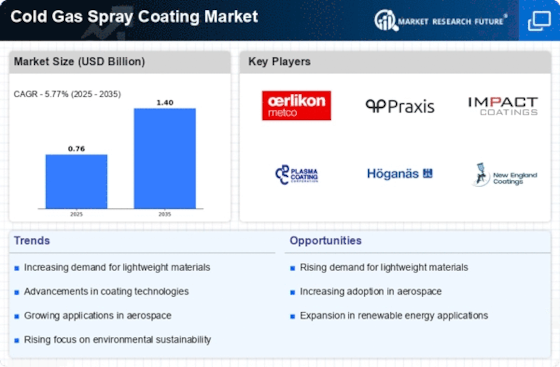

The Cold Gas Spray Coating Market is experiencing a notable surge in demand for wear-resistant coatings across various sectors, including aerospace, automotive, and manufacturing. This demand is primarily driven by the need for enhanced durability and longevity of components subjected to harsh operating conditions. As industries increasingly prioritize performance and reliability, the adoption of cold gas spray technology is likely to rise. Reports indicate that the wear-resistant coatings segment is projected to grow at a compound annual growth rate (CAGR) of approximately 7% over the next five years. This growth reflects a broader trend towards advanced materials that can withstand wear and tear, thereby reducing maintenance costs and downtime. Consequently, the Cold Gas Spray Coating Market is poised to benefit from this increasing focus on durability and performance.

Technological Innovations in Coating Processes

Technological advancements are playing a pivotal role in shaping the Cold Gas Spray Coating Market. Innovations in coating processes, such as the development of new nozzle designs and improved powder feed systems, are enhancing the efficiency and effectiveness of cold gas spray applications. These advancements enable better control over coating thickness and uniformity, which are critical for achieving desired performance characteristics. Furthermore, the integration of automation and robotics in coating processes is streamlining operations and reducing labor costs. Market analysis indicates that the technological innovations segment is projected to grow at a CAGR of around 6% in the coming years. This growth underscores the importance of continuous improvement in coating technologies, which is essential for maintaining competitiveness in the Cold Gas Spray Coating Market.

.png)