Rising Demand for Energy

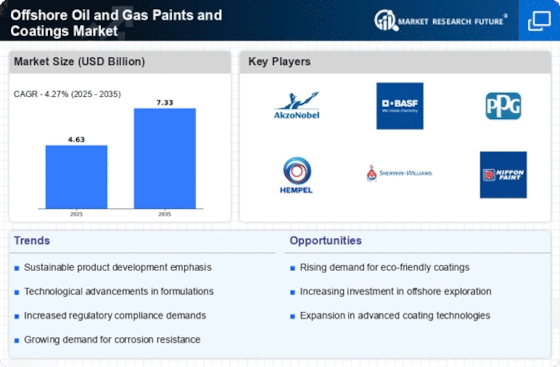

The Offshore Oil Gas Paints And Coating Market is experiencing a surge in demand driven by the increasing global energy requirements. As nations strive to meet their energy needs, offshore oil and gas exploration and production activities are expanding. This growth necessitates the use of specialized paints and coatings that can withstand harsh marine environments. According to industry reports, the offshore oil and gas sector is projected to grow at a compound annual growth rate of approximately 5% over the next few years. This growth translates into a heightened demand for protective coatings that ensure the longevity and efficiency of offshore structures, thereby propelling the Offshore Oil Gas Paints And Coating Market forward.

Technological Innovations in Coatings

Technological advancements are playing a pivotal role in shaping the Offshore Oil Gas Paints And Coating Market. Innovations such as the development of high-performance coatings that offer enhanced durability and resistance to corrosion are becoming increasingly prevalent. These advanced coatings are designed to withstand extreme conditions, including high salinity and temperature fluctuations, which are characteristic of offshore environments. The introduction of smart coatings that can provide real-time monitoring of structural integrity is also gaining traction. As a result, companies are investing in research and development to create coatings that not only protect but also enhance the operational efficiency of offshore installations, thereby driving growth in the Offshore Oil Gas Paints And Coating Market.

Environmental Regulations and Compliance

The Offshore Oil Gas Paints And Coating Market is significantly influenced by stringent environmental regulations aimed at reducing the ecological impact of offshore operations. Regulatory bodies are enforcing guidelines that mandate the use of environmentally friendly coatings, which has led to a shift towards low-VOC and water-based products. Compliance with these regulations is not only essential for operational licenses but also for maintaining corporate responsibility. As companies adapt to these regulations, the demand for compliant coatings is expected to rise. This trend is likely to create opportunities for manufacturers who specialize in eco-friendly products, thereby shaping the future landscape of the Offshore Oil Gas Paints And Coating Market.

Focus on Maintenance and Asset Longevity

The Offshore Oil Gas Paints And Coating Market is also driven by a heightened focus on maintenance and asset longevity. Operators are increasingly recognizing the importance of protective coatings in extending the lifespan of offshore structures. Regular maintenance and the application of high-quality coatings can significantly reduce the risk of corrosion and structural failure, which are critical concerns in offshore environments. As a result, there is a growing trend towards investing in advanced coatings that offer long-term protection. This focus on maintenance not only enhances operational efficiency but also reduces overall costs associated with repairs and replacements, thereby fostering growth in the Offshore Oil Gas Paints And Coating Market.

Increased Investment in Offshore Projects

Investment in offshore oil and gas projects is on the rise, which is a key driver for the Offshore Oil Gas Paints And Coating Market. As companies seek to tap into untapped reserves, there is a growing need for reliable and durable coatings that can protect infrastructure from the corrosive effects of seawater and other environmental factors. Recent data indicates that capital expenditures in offshore projects are expected to increase, leading to a corresponding demand for high-quality paints and coatings. This influx of investment not only supports the growth of the Offshore Oil Gas Paints And Coating Market but also encourages innovation in product development to meet the evolving needs of the sector.