Technological Innovations

Technological advancements play a pivotal role in shaping the Cold Heading Machine Market. The introduction of automated systems and smart manufacturing technologies has revolutionized production processes. For instance, the integration of Industry 4.0 principles allows for real-time monitoring and predictive maintenance, which enhances operational efficiency. Furthermore, the development of high-speed cold heading machines has enabled manufacturers to increase output while maintaining precision. According to recent data, the market for advanced cold heading machines is expected to grow significantly, with a projected increase in market size by 7% annually. This trend indicates that companies are increasingly investing in innovative technologies to remain competitive in the Cold Heading Machine Market.

Rising Demand for Fasteners

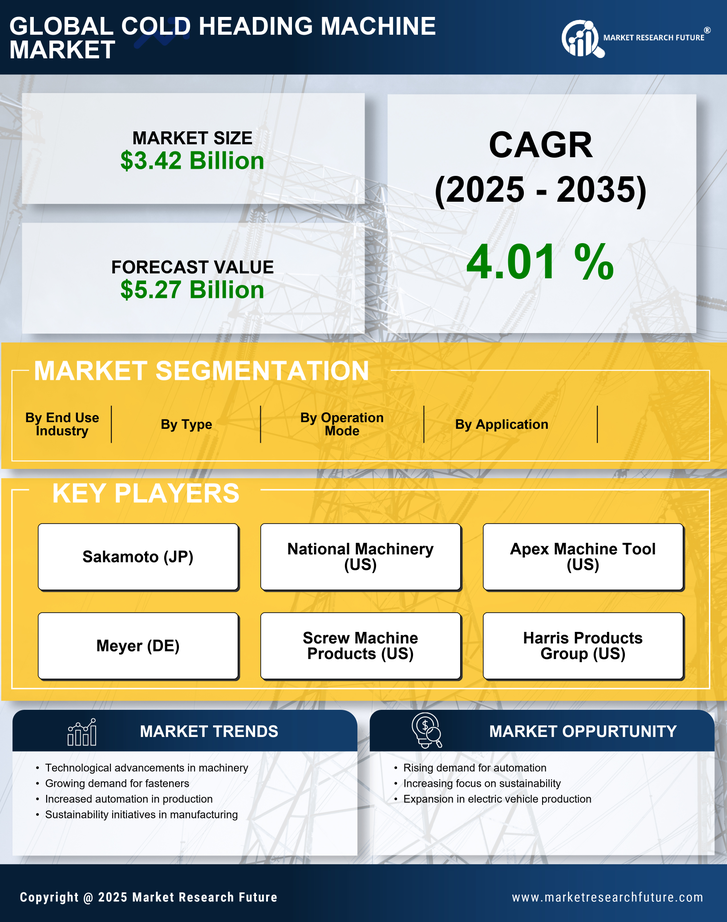

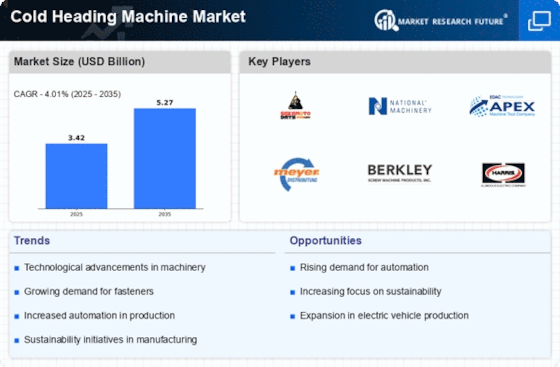

The Cold Heading Machine Market is experiencing a notable increase in demand for fasteners, driven by the expanding automotive and construction sectors. Fasteners are essential components in various applications, and their demand is projected to grow at a compound annual growth rate of approximately 5.2% over the next few years. This growth is largely attributed to the increasing production of vehicles and infrastructure projects, which require high-quality fasteners for assembly and structural integrity. As manufacturers seek to enhance production efficiency, the adoption of advanced cold heading machines becomes crucial. These machines not only improve the quality of fasteners but also reduce production costs, thereby positioning themselves as a vital asset in the Cold Heading Machine Market.

Increasing Focus on Energy Efficiency

Energy efficiency has emerged as a critical focus within the Cold Heading Machine Market. Manufacturers are increasingly seeking machines that consume less energy while delivering high performance. This shift is driven by both regulatory pressures and the desire to reduce operational costs. Recent studies indicate that energy-efficient cold heading machines can reduce energy consumption by up to 30%, which is a significant factor for manufacturers aiming to enhance sustainability. As a result, companies are investing in the development of machines that incorporate energy-saving technologies. This trend not only aligns with The Cold Heading Machine Industry, as they can offer more competitive pricing and improved environmental compliance.

Expansion of Manufacturing Capabilities

The Cold Heading Machine Market is experiencing a transformation as manufacturers expand their production capabilities to meet growing demand. This expansion is driven by the need for higher production volumes and the ability to produce a wider variety of fasteners. Recent data suggests that the market for cold heading machines is expected to grow by 6% annually, reflecting the increasing investment in manufacturing infrastructure. Companies are focusing on upgrading existing machines and acquiring new technologies to enhance their production lines. This trend not only improves efficiency but also allows manufacturers to respond more effectively to market fluctuations. As a result, the Cold Heading Machine Market is poised for continued growth, driven by the strategic expansion of manufacturing capabilities.

Growth in Aerospace and Defense Sectors

The Cold Heading Machine Market is witnessing substantial growth due to the rising demand from the aerospace and defense sectors. These industries require high-performance fasteners that can withstand extreme conditions, necessitating the use of advanced cold heading machines for production. The aerospace sector, in particular, is projected to grow at a rate of 4.5% annually, leading to an increased need for precision-engineered components. As manufacturers strive to meet stringent quality standards, the adoption of specialized cold heading machines becomes essential. This trend not only supports the production of high-quality fasteners but also drives innovation within the Cold Heading Machine Market, as companies seek to develop machines that cater specifically to these demanding applications.