Increasing Electronics Production

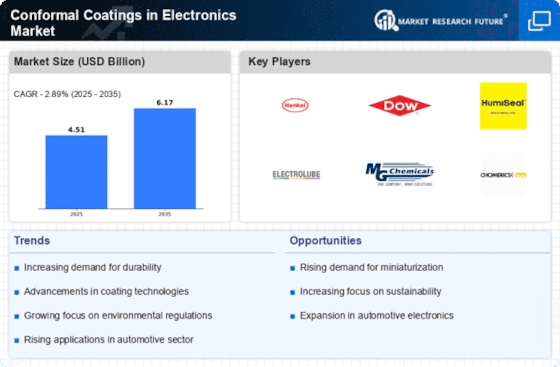

The Conformal Coatings in Electronics Market is experiencing a notable surge due to the increasing production of electronic devices. As consumer demand for smartphones, tablets, and wearables continues to rise, manufacturers are compelled to enhance the durability and reliability of their products. This trend is reflected in the projected growth of the electronics sector, which is expected to reach a valuation of over 1 trillion dollars by 2025. Conformal coatings play a crucial role in protecting sensitive electronic components from moisture, dust, and chemicals, thereby extending the lifespan of devices. Consequently, the demand for these coatings is likely to escalate, as manufacturers seek to meet consumer expectations for high-performance electronics.

Expansion of Automotive Electronics

The Conformal Coatings in Electronics Market is significantly impacted by the expansion of automotive electronics. As vehicles become more technologically advanced, incorporating features such as advanced driver-assistance systems (ADAS) and infotainment systems, the need for reliable electronic components is paramount. The automotive electronics market is anticipated to grow substantially, with estimates suggesting a valuation exceeding 300 billion dollars by 2025. Conformal coatings are essential in protecting these components from harsh automotive environments, including temperature fluctuations and moisture exposure. As the automotive industry increasingly adopts electronic solutions, the demand for conformal coatings is expected to rise, contributing to the overall growth of the market.

Regulatory Compliance and Standards

The Conformal Coatings in Electronics Market is significantly influenced by the need for compliance with stringent regulatory standards. Various industries, including automotive and aerospace, are subject to regulations that mandate the use of protective coatings to ensure safety and reliability. For instance, the IPC-610 standard outlines the requirements for electronic assemblies, emphasizing the importance of conformal coatings in preventing failures. As companies strive to adhere to these regulations, the demand for high-quality conformal coatings is expected to rise. This compliance not only enhances product safety but also fosters consumer trust, thereby driving market growth in the conformal coatings sector.

Rising Demand for Consumer Electronics

The Conformal Coatings in Electronics Market is propelled by the rising demand for consumer electronics. With the proliferation of smart devices, including smart home appliances and IoT devices, manufacturers are increasingly focusing on the reliability and longevity of their products. The consumer electronics market is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next few years. This growth is expected to drive the demand for conformal coatings, as they provide essential protection against environmental stressors. As consumers become more discerning about product quality, the need for effective conformal coatings will likely intensify, further fueling market expansion.

Technological Advancements in Coating Applications

The Conformal Coatings in Electronics Market is witnessing a transformation due to technological advancements in coating applications. Innovations such as automated spraying and selective coating technologies are enhancing the efficiency and precision of coating processes. These advancements allow for better coverage of complex geometries and reduce material waste, which is particularly beneficial in high-volume production environments. Furthermore, the introduction of new materials, such as nanocoatings, is expanding the capabilities of conformal coatings, offering superior protection against environmental factors. As manufacturers adopt these advanced technologies, the market for conformal coatings is likely to expand, driven by the need for enhanced performance and cost-effectiveness.

Leave a Comment