Advancements in Soldering Technology

Technological innovations in soldering processes are reshaping the convection reflow soldering oven Market. The introduction of advanced heating techniques, such as infrared and hot air convection, has improved the efficiency and effectiveness of soldering operations. These advancements allow for better temperature control and uniform heating, which are critical for achieving optimal soldering results. Furthermore, the integration of smart technologies, such as IoT and automation, is enhancing the capabilities of convection reflow soldering ovens. This is reflected in the increasing adoption of automated soldering solutions, which are expected to account for a significant share of the market. As manufacturers seek to improve production efficiency and reduce defects, the demand for technologically advanced soldering ovens is likely to rise, driving market growth.

Increasing Demand for Miniaturization

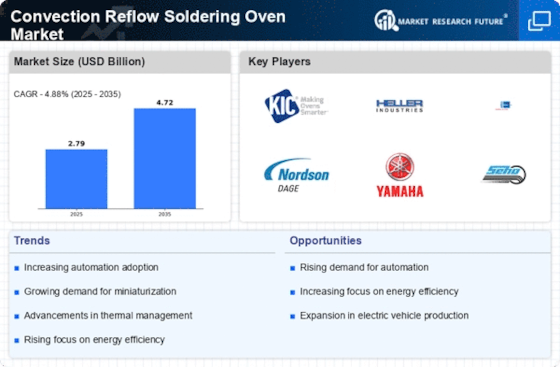

The trend towards miniaturization in electronics is a primary driver for the Convection Reflow Soldering Oven Market. As devices become smaller and more compact, the need for precise soldering techniques increases. This trend is particularly evident in sectors such as consumer electronics, automotive, and telecommunications, where space constraints necessitate advanced soldering solutions. The market for miniaturized components is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 10% in the coming years. Consequently, manufacturers are increasingly investing in convection reflow soldering ovens that can accommodate these smaller components while ensuring high-quality solder joints. This shift not only enhances product performance but also aligns with the evolving demands of consumers for more efficient and compact devices.

Rising Focus on Quality and Reliability

Quality assurance is becoming increasingly crucial in the Convection Reflow Soldering Oven Market. As industries strive for higher standards in product reliability, the demand for precise soldering processes is intensifying. This is particularly relevant in sectors such as aerospace, medical devices, and automotive, where product failure can have severe consequences. The need for reliable solder joints has led to a growing preference for convection reflow soldering ovens, which offer superior thermal management and consistent results. Market data indicates that the quality control segment is expected to witness substantial growth, as manufacturers invest in equipment that ensures compliance with stringent industry standards. This focus on quality not only enhances product performance but also reduces the risk of recalls and warranty claims, further driving the demand for advanced soldering solutions.

Sustainability and Environmental Regulations

The increasing emphasis on sustainability and environmental regulations is influencing the Convection Reflow Soldering Oven Market. Manufacturers are under pressure to adopt eco-friendly practices and reduce their carbon footprint. This has led to the development of soldering technologies that minimize energy consumption and waste generation. For instance, convection reflow soldering ovens that utilize energy-efficient heating methods are gaining traction as companies seek to comply with environmental standards. Additionally, the shift towards lead-free soldering materials is becoming more prevalent, driven by regulatory requirements and consumer preferences for safer products. As a result, the market for convection reflow soldering ovens that support sustainable practices is expected to expand, reflecting a broader trend towards environmentally responsible manufacturing.

Growth of the Electronics Manufacturing Sector

The expansion of the electronics manufacturing sector is a significant driver for the Convection Reflow Soldering Oven Market. With the proliferation of electronic devices across various applications, including consumer electronics, industrial automation, and telecommunications, the demand for efficient soldering solutions is on the rise. Market analysis indicates that the electronics manufacturing industry is projected to grow at a robust pace, with an increasing number of companies investing in advanced soldering technologies to enhance production capabilities. This growth is further fueled by the rising adoption of smart devices and the Internet of Things, which require sophisticated soldering processes. As manufacturers seek to meet the growing demand for high-quality electronic products, the need for reliable convection reflow soldering ovens is likely to increase, driving market growth.