Government Support and Subsidies

Government initiatives aimed at boosting the agricultural sector significantly influence the Cotton Ginning Machine Market. Various countries are implementing policies that provide financial support and subsidies to cotton farmers and ginning operations. These measures are designed to enhance productivity and promote the use of modern ginning technologies. For instance, recent reports indicate that several governments have allocated substantial budgets to support the modernization of ginning facilities. This financial backing not only encourages the adoption of advanced machinery but also fosters a competitive environment within the Cotton Ginning Machine Market, ultimately benefiting stakeholders across the supply chain.

Expansion of Cotton Cultivation Areas

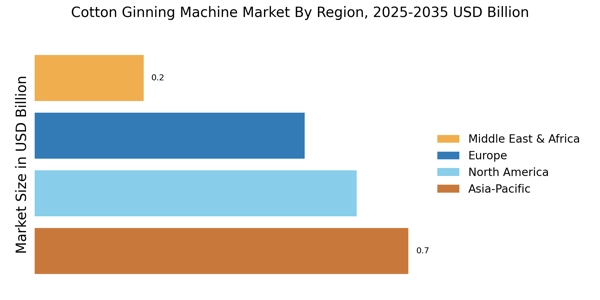

The expansion of cotton cultivation areas is a significant driver for the Cotton Ginning Machine Market. As countries explore new agricultural frontiers, the area dedicated to cotton farming is projected to increase. Recent estimates suggest that cotton acreage could rise by approximately 10% over the next five years, particularly in regions with favorable climatic conditions. This expansion necessitates the deployment of efficient ginning machines to process the anticipated increase in cotton yield. As a result, manufacturers are likely to experience heightened demand for their products, further propelling growth within the Cotton Ginning Machine Market.

Increasing Demand for Cotton Products

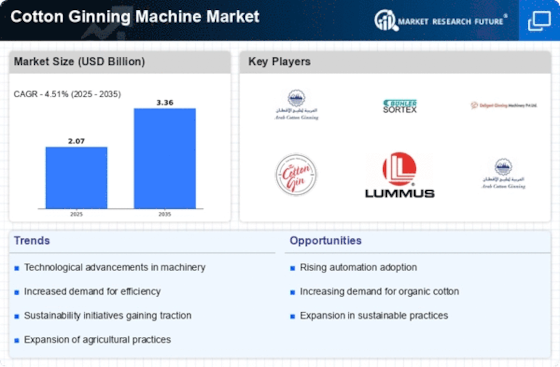

The rising demand for cotton products, driven by the textile and apparel industries, is a primary driver for the Cotton Ginning Machine Market. As consumer preferences shift towards natural fibers, the need for efficient cotton processing becomes paramount. In recent years, the cotton production has seen fluctuations, with estimates indicating a production of approximately 25 million metric tons in 2025. This surge in cotton production necessitates advanced ginning technologies to ensure quality and efficiency. Consequently, manufacturers are investing in innovative ginning machines that enhance productivity and reduce waste, thereby supporting the growth of the Cotton Ginning Machine Market.

Rising Awareness of Sustainable Practices

The growing emphasis on sustainability within the textile industry is reshaping the Cotton Ginning Machine Market. As consumers become more environmentally conscious, there is an increasing demand for sustainable cotton production methods. This trend is prompting ginning machine manufacturers to develop eco-friendly technologies that minimize waste and energy consumption. Recent studies indicate that sustainable ginning practices can reduce carbon emissions by up to 40%. Consequently, the shift towards sustainability is likely to drive innovation and investment in the Cotton Ginning Machine Market, as companies seek to align with consumer expectations and regulatory standards.

Technological Innovations in Ginning Processes

Technological advancements play a crucial role in shaping the Cotton Ginning Machine Market. Innovations such as automated ginning systems and improved separation techniques are enhancing operational efficiency. The integration of artificial intelligence and machine learning in ginning processes is expected to optimize performance and reduce labor costs. Recent data suggests that the adoption of these technologies could increase ginning efficiency by up to 30%. As manufacturers strive to meet the evolving demands of the market, the emphasis on research and development in ginning technology is likely to drive growth in the Cotton Ginning Machine Market.

.png)