Growth in Chemical Processing

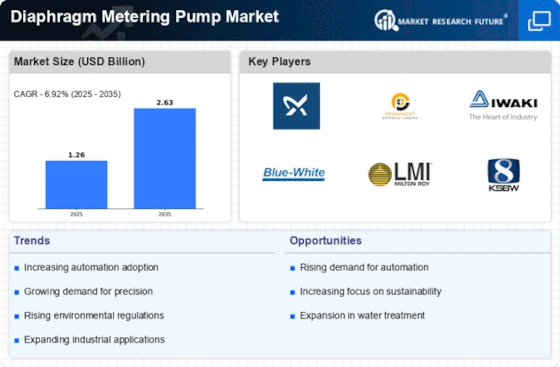

The chemical processing industry is experiencing notable expansion, which significantly influences the Diaphragm Metering Pump Market. As production processes become more complex, the need for precise and reliable dosing of chemicals has become paramount. Diaphragm metering pumps are particularly well-suited for this application due to their ability to handle a wide range of fluids, including corrosive and viscous materials. Market analysis suggests that the chemical processing sector is expected to grow at a rate of around 5% annually, driven by increased demand for specialty chemicals and advanced materials. This growth presents a substantial opportunity for diaphragm metering pumps, as they are integral to maintaining efficiency and safety in chemical manufacturing.

Rising Demand in Water Treatment

The increasing necessity for efficient water treatment solutions is a primary driver for the Diaphragm Metering Pump Market. As municipalities and industries strive to meet stringent environmental regulations, the demand for precise chemical dosing in water treatment processes has surged. Diaphragm metering pumps are favored for their accuracy and reliability, ensuring optimal chemical usage. According to recent data, the water treatment sector is projected to grow at a compound annual growth rate of approximately 6% over the next few years, further propelling the need for advanced metering solutions. This trend indicates a robust market potential for diaphragm metering pumps, as they play a crucial role in enhancing water quality and compliance with environmental standards.

Increased Focus on Industrial Automation

The trend towards industrial automation is reshaping various sectors, including the Diaphragm Metering Pump Market. As industries adopt automated systems to enhance productivity and reduce operational costs, the demand for precise fluid handling solutions has escalated. Diaphragm metering pumps, known for their accuracy and ease of integration into automated systems, are becoming increasingly popular. The automation market is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 9% in the coming years. This shift towards automation not only enhances operational efficiency but also drives the need for advanced metering technologies, positioning diaphragm metering pumps as essential components in modern industrial applications.

Regulatory Compliance and Safety Standards

Stringent regulatory compliance and safety standards across various industries are pivotal drivers for the Diaphragm Metering Pump Market. Industries such as pharmaceuticals, food and beverage, and chemicals are subject to rigorous regulations that mandate precise dosing and handling of hazardous materials. Diaphragm metering pumps are recognized for their ability to provide accurate and safe fluid transfer, making them a preferred choice in these sectors. The increasing emphasis on safety and compliance is likely to propel the demand for diaphragm metering pumps, as companies seek reliable solutions to meet regulatory requirements. This trend underscores the importance of investing in high-quality metering technologies to ensure operational integrity and safety.

Emerging Markets and Infrastructure Development

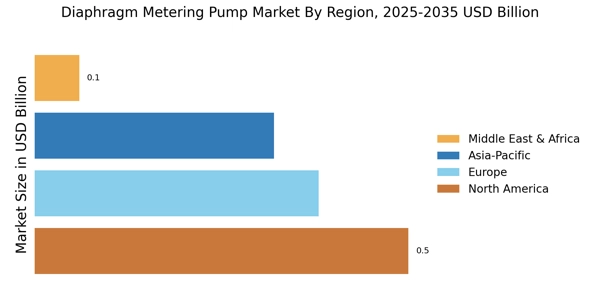

Emerging markets are witnessing rapid infrastructure development, which serves as a significant driver for the Diaphragm Metering Pump Market. As countries invest in new facilities, particularly in water treatment, chemical processing, and manufacturing, the demand for reliable metering solutions is on the rise. Diaphragm metering pumps are essential for ensuring accurate dosing in these applications, thereby supporting the growth of infrastructure projects. Recent reports indicate that infrastructure spending in developing regions is expected to increase substantially, with investments in water and wastewater management projected to reach billions. This influx of capital into infrastructure development presents a lucrative opportunity for diaphragm metering pump manufacturers, as they cater to the growing needs of these expanding markets.