Growth in Semiconductor Industry

The Dicing Die Attach Film Market is closely linked to the growth of the semiconductor industry, which is currently experiencing robust expansion. As semiconductor manufacturers ramp up production to meet the increasing demand for chips in various applications, the need for efficient die attach solutions becomes paramount. The semiconductor market is projected to reach USD 600 billion by 2025, which directly correlates with the rising demand for dicing die attach films. These films play a critical role in ensuring the reliability and performance of semiconductor devices, thereby driving their adoption. The synergy between the semiconductor industry's growth and the dicing die attach film market is likely to foster innovation and enhance market dynamics in the coming years.

Rising Demand for Miniaturization

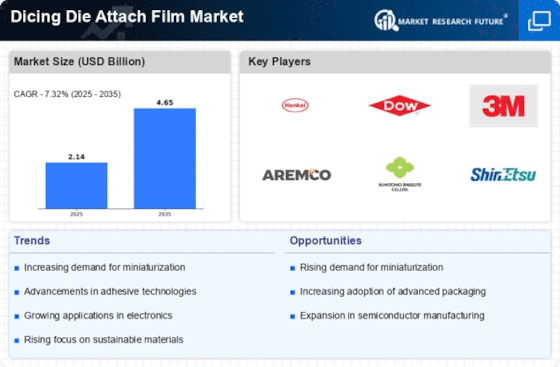

The Dicing Die Attach Film Market is experiencing a notable surge in demand driven by the trend towards miniaturization in electronic devices. As consumer electronics evolve, manufacturers are increasingly seeking materials that facilitate the production of smaller, more efficient components. This trend is particularly evident in sectors such as smartphones, wearables, and IoT devices, where space constraints necessitate the use of advanced die attach films. The market for dicing die attach films is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years, reflecting the industry's response to these evolving consumer preferences. Furthermore, the ability of these films to enhance thermal conductivity and mechanical strength makes them indispensable in the production of compact electronic assemblies.

Expansion of Automotive Electronics

The Dicing Die Attach Film Market is significantly influenced by the expansion of automotive electronics, which is becoming a key driver of market growth. With the automotive sector increasingly integrating advanced electronic systems for safety, navigation, and entertainment, the demand for reliable die attach solutions is escalating. The automotive electronics market is projected to exceed USD 300 billion by 2025, creating substantial opportunities for dicing die attach films. These films are essential for ensuring the durability and performance of electronic components in vehicles, particularly in the context of electric and autonomous vehicles. As the automotive industry continues to evolve, the demand for high-quality dicing die attach films is likely to increase, further propelling market growth.

Increasing Focus on Energy Efficiency

The Dicing Die Attach Film Market is witnessing a growing emphasis on energy efficiency, particularly in the context of electronic device manufacturing. As industries strive to reduce their carbon footprint and enhance sustainability, the demand for materials that contribute to energy-efficient designs is on the rise. Dicing die attach films, known for their excellent thermal management properties, are becoming increasingly popular in applications where heat dissipation is critical. This trend is expected to drive market growth, as manufacturers seek to optimize their products for energy efficiency. The market is anticipated to grow by approximately 5% annually, reflecting the industry's commitment to sustainability and energy conservation.

Technological Innovations in Film Production

Technological advancements in the production of dicing die attach films are significantly influencing the Dicing Die Attach Film Market. Innovations such as the development of high-performance adhesive materials and improved manufacturing processes are enhancing the quality and reliability of these films. For instance, the introduction of films with superior thermal and electrical properties is enabling manufacturers to meet the stringent requirements of modern semiconductor applications. The market is witnessing an influx of new products that offer enhanced performance characteristics, which could potentially lead to increased adoption across various sectors. As a result, the market is expected to expand, with estimates suggesting a valuation of over USD 1 billion by 2026, driven by these technological advancements.