Technological Advancements

The Wafer Dicing Saws Market is experiencing a surge in technological advancements, particularly in precision cutting and automation. Innovations such as laser dicing and advanced blade materials are enhancing the efficiency and accuracy of wafer dicing processes. These advancements not only reduce material waste but also improve yield rates, which is crucial in semiconductor manufacturing. As the demand for smaller and more powerful electronic devices increases, the need for high-precision dicing saws becomes more pronounced. The market is projected to grow at a compound annual growth rate (CAGR) of approximately 5.2% over the next few years, driven by these technological improvements that cater to the evolving needs of the electronics sector.

Rising Demand for Semiconductors

The Wafer Dicing Saws Market is significantly influenced by the rising demand for semiconductors across various sectors, including automotive, consumer electronics, and telecommunications. As industries increasingly rely on advanced semiconductor technologies, the need for efficient wafer dicing solutions becomes paramount. The semiconductor market is expected to reach a valuation of over 600 billion USD by 2025, which directly correlates with the growth of the wafer dicing saws market. This demand is further fueled by the proliferation of IoT devices and smart technologies, necessitating high-quality dicing saws to meet production requirements. Consequently, manufacturers are investing in advanced dicing technologies to enhance their production capabilities.

Increased Focus on Miniaturization

The trend towards miniaturization in electronic devices is a key driver for the Wafer Dicing Saws Market. As manufacturers strive to produce smaller, more compact components, the precision required in wafer dicing becomes increasingly critical. This trend is evident in sectors such as mobile devices, wearables, and medical technology, where space constraints demand high levels of accuracy in component fabrication. The market for miniaturized electronic components is projected to grow, thereby increasing the demand for advanced dicing saws that can handle intricate designs and tight tolerances. This focus on miniaturization not only drives innovation in dicing technologies but also enhances the overall efficiency of production processes.

Growing Adoption of Electric Vehicles

The Wafer Dicing Saws Market is poised to benefit from the growing adoption of electric vehicles (EVs). As the automotive industry shifts towards electrification, the demand for advanced semiconductor components used in EVs is on the rise. These components require precise dicing solutions to ensure optimal performance and reliability. The electric vehicle market is expected to witness substantial growth, with projections indicating that EV sales could reach 30 million units annually by 2030. This surge in demand for EVs translates into increased requirements for wafer dicing saws, as manufacturers seek to produce high-quality semiconductor devices that meet the stringent performance standards of the automotive sector.

Emerging Markets and Investment Opportunities

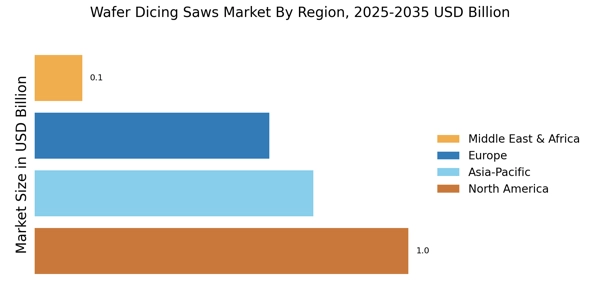

The Wafer Dicing Saws Market is also being driven by emerging markets that present new investment opportunities. Countries in Asia-Pacific and Latin America are witnessing rapid industrialization and technological advancements, leading to increased demand for semiconductor manufacturing. As these regions invest in their manufacturing capabilities, the need for efficient wafer dicing solutions becomes more pronounced. The expansion of semiconductor fabrication facilities in these emerging markets is likely to create a robust demand for advanced dicing saws. Furthermore, government initiatives aimed at boosting local manufacturing capabilities are expected to further stimulate growth in the wafer dicing saws market, making it an attractive area for investment.