Growing Emphasis on Sustainability

The Digital Servo Press Market is witnessing a growing emphasis on sustainability and environmentally friendly manufacturing practices. Companies are increasingly adopting digital servo presses to minimize energy consumption and reduce their carbon footprint. The energy efficiency of digital servo presses, which can lead to a reduction in operational costs, is becoming a key selling point. Recent studies indicate that energy-efficient manufacturing processes can lower energy usage by up to 30%. As sustainability becomes a priority for manufacturers, the Digital Servo Press Market is expected to see a rise in demand for eco-friendly solutions.

Technological Advancements in Automation

Technological advancements play a pivotal role in shaping the Digital Servo Press Market. Innovations in automation technologies, such as artificial intelligence and machine learning, are enhancing the capabilities of digital servo presses. These advancements allow for real-time monitoring and adjustments during the manufacturing process, leading to improved efficiency and reduced downtime. The market for automation solutions is expected to expand significantly, with estimates suggesting a growth rate of around 8% annually. As manufacturers increasingly invest in these technologies, the Digital Servo Press Market is likely to benefit from enhanced operational efficiencies and productivity.

Rising Demand for Precision Manufacturing

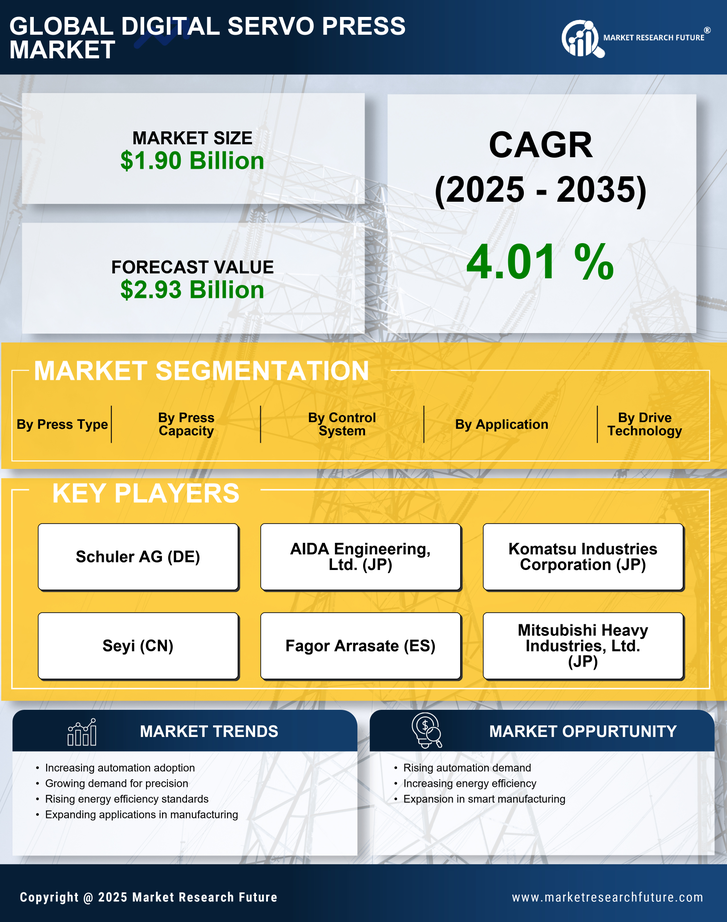

The Digital Servo Press Market is experiencing a notable surge in demand for precision manufacturing processes. Industries such as automotive, aerospace, and electronics are increasingly adopting digital servo presses to enhance accuracy and reduce waste. This trend is driven by the need for high-quality components that meet stringent specifications. According to recent data, the precision manufacturing sector is projected to grow at a compound annual growth rate of approximately 6% over the next five years. As manufacturers seek to improve their production capabilities, the integration of digital servo presses becomes essential, thereby propelling the Digital Servo Press Market forward.

Increased Investment in Smart Manufacturing

The Digital Servo Press Market is benefiting from increased investment in smart manufacturing initiatives. As industries strive to enhance productivity and reduce costs, the integration of smart technologies into manufacturing processes is becoming more prevalent. Digital servo presses, equipped with advanced sensors and connectivity features, are at the forefront of this transformation. The smart manufacturing market is anticipated to grow at a rate of approximately 10% annually, indicating a robust interest in innovative manufacturing solutions. This trend is likely to bolster the Digital Servo Press Market as manufacturers seek to leverage smart technologies for improved operational efficiency.

Customization and Adaptability in Production

Customization and adaptability are becoming critical factors in the Digital Servo Press Market. As consumer preferences shift towards personalized products, manufacturers are compelled to adopt flexible production methods. Digital servo presses offer the ability to easily adjust settings for different production runs, enabling manufacturers to respond swiftly to market demands. This adaptability is particularly valuable in industries such as consumer electronics and fashion, where trends can change rapidly. The market for customizable manufacturing solutions is projected to grow, further driving the adoption of digital servo presses in various sectors.