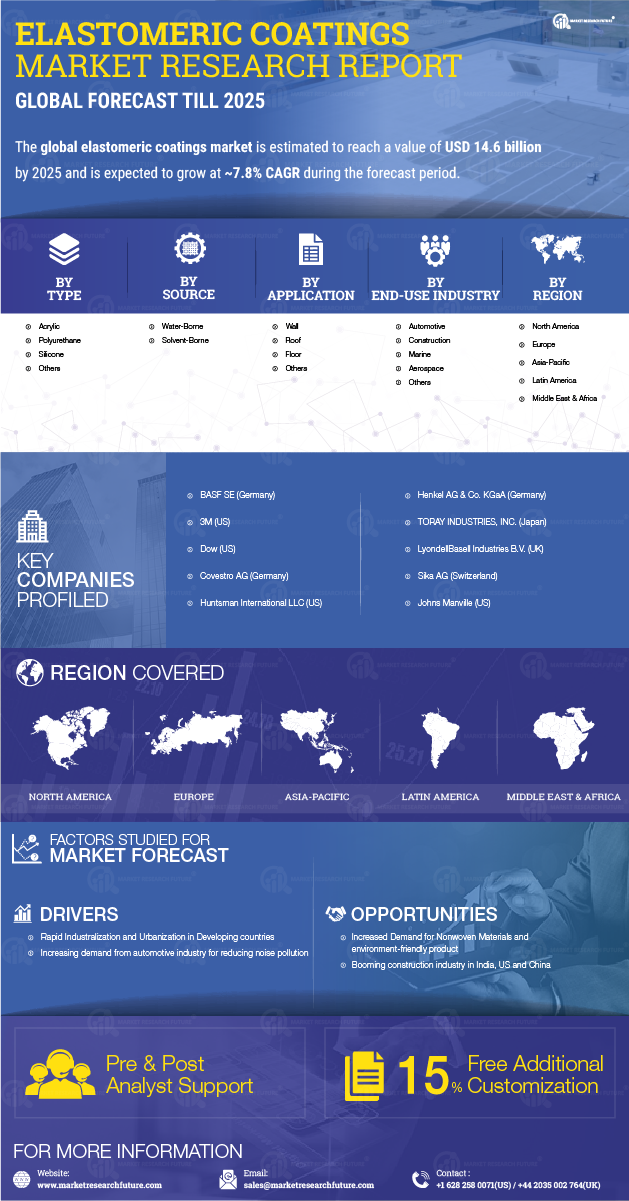

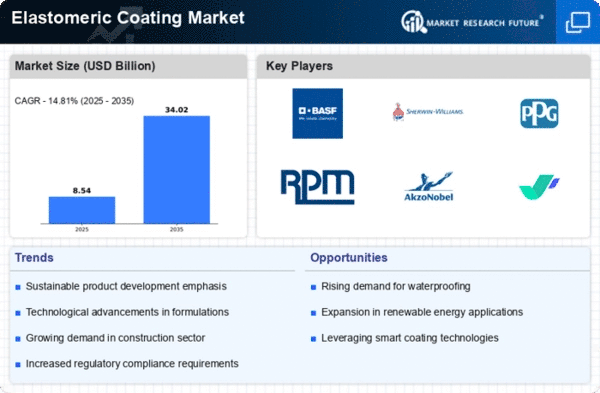

Market Growth Projections

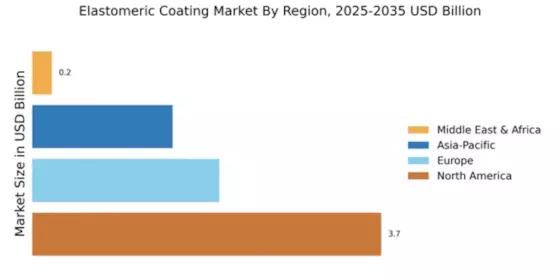

The Global Elastomeric Coatings Market Industry is projected to experience robust growth over the next decade. With a market value expected to reach 10.3 USD Billion in 2024 and further expand to 24.7 USD Billion by 2035, the industry is on a promising trajectory. The anticipated compound annual growth rate of 8.28% from 2025 to 2035 indicates a strong demand for elastomeric coatings across various sectors. This growth is driven by factors such as increasing infrastructure projects, technological advancements, and a rising emphasis on sustainability. The market's expansion reflects the evolving needs of industries seeking durable and efficient coating solutions.

Infrastructure Development Initiatives

Infrastructure development initiatives worldwide significantly bolster the Global Elastomeric Coatings Market Industry. Governments are investing heavily in infrastructure projects, including roads, bridges, and buildings, which require protective coatings to enhance durability and longevity. Elastomeric coatings are particularly favored for their ability to withstand harsh weather conditions and provide waterproofing solutions. For example, in urban areas, the application of these coatings on structures helps mitigate water damage and prolong asset life. This trend is expected to contribute to the market's expansion, with projections indicating a growth to 24.7 USD Billion by 2035.

Rising Demand for Sustainable Solutions

The Global Elastomeric Coatings Market Industry experiences a notable surge in demand for sustainable and eco-friendly coatings. As industries increasingly prioritize environmental responsibility, elastomeric coatings, which are often water-based and low in volatile organic compounds, gain traction. This shift aligns with global sustainability initiatives, prompting manufacturers to innovate and develop greener products. For instance, the construction sector is adopting these coatings for their energy efficiency and durability, contributing to the projected market growth. The market is anticipated to reach 10.3 USD Billion in 2024, reflecting a growing preference for sustainable solutions.

Growing Awareness of Protective Coatings

Growing awareness of the benefits of protective coatings significantly influences the Global Elastomeric Coatings Market Industry. End-users across various sectors, including construction and automotive, are increasingly recognizing the importance of protective coatings in extending the lifespan of assets and reducing maintenance costs. Elastomeric coatings provide superior protection against moisture, chemicals, and physical wear, making them an attractive option for many applications. This heightened awareness is driving demand, as industries seek to invest in long-lasting solutions. Consequently, the market is poised for substantial growth as more stakeholders prioritize protective coatings in their projects.

Regulatory Support for Coating Standards

Regulatory support for coating standards enhances the credibility and growth potential of the Global Elastomeric Coatings Market Industry. Governments and regulatory bodies are establishing stringent guidelines to ensure the quality and safety of coatings used in various applications. These regulations often favor the use of elastomeric coatings due to their favorable environmental profiles and performance characteristics. Compliance with these standards not only boosts consumer confidence but also encourages manufacturers to innovate and improve their product offerings. As a result, the market is likely to benefit from increased adoption and investment in elastomeric coatings.

Technological Advancements in Coating Formulations

Technological advancements in coating formulations play a pivotal role in shaping the Global Elastomeric Coatings Market Industry. Innovations in polymer chemistry and application techniques enhance the performance characteristics of elastomeric coatings, such as adhesion, flexibility, and resistance to UV degradation. These advancements enable manufacturers to create products that meet diverse industry needs, from construction to automotive applications. As a result, the market is likely to witness increased adoption of high-performance coatings, further driving growth. The anticipated compound annual growth rate of 8.28% from 2025 to 2035 underscores the potential of these technological developments.