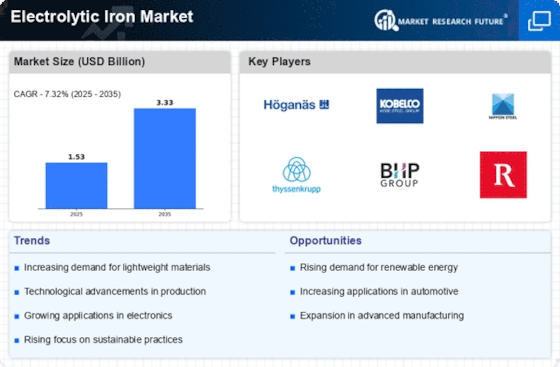

Growth in Renewable Energy Sector

The Electrolytic Iron Market is poised to benefit from the rapid expansion of the renewable energy sector. As the world shifts towards cleaner energy sources, the demand for materials used in renewable energy technologies, such as wind turbines and solar panels, is on the rise. Electrolytic iron, known for its excellent magnetic properties, is increasingly being utilized in the production of components for these technologies. The renewable energy market is projected to grow at a compound annual growth rate of approximately 8% over the next decade, which could significantly drive the demand for electrolytic iron. This growth presents a substantial opportunity for manufacturers to diversify their product offerings and cater to the evolving needs of the renewable energy industry.

Rising Demand in Steel Production

The Electrolytic Iron Market is experiencing a notable surge in demand due to the increasing production of steel. Electrolytic iron serves as a critical raw material in the manufacturing of high-quality steel, which is essential for various applications, including construction and automotive industries. As steel production is projected to grow at a compound annual growth rate of approximately 3.5% over the next few years, the demand for electrolytic iron is likely to follow suit. This trend indicates a robust market for electrolytic iron, as manufacturers seek to enhance the quality and performance of their steel products. Furthermore, the shift towards high-strength steel grades necessitates the use of electrolytic iron, thereby reinforcing its importance in the steel production process.

Increasing Applications in Electronics

The Electrolytic Iron Market is benefiting from the expanding applications of electrolytic iron in the electronics sector. As the demand for electronic components continues to rise, electrolytic iron is increasingly utilized in the production of magnetic materials and other electronic devices. The market for electronic components is projected to grow significantly, with estimates suggesting a compound annual growth rate of around 5% over the next five years. This growth is likely to drive the demand for electrolytic iron, as manufacturers seek materials that offer superior magnetic properties and conductivity. Consequently, the integration of electrolytic iron in electronic applications is expected to create new opportunities for market players, further diversifying the applications of this versatile material.

Advancements in Manufacturing Technologies

Technological innovations within the Electrolytic Iron Market are playing a pivotal role in enhancing production efficiency and product quality. Recent advancements in electrolytic processes have led to improved purity levels and reduced production costs. For instance, the implementation of automated systems and real-time monitoring technologies has streamlined operations, allowing manufacturers to optimize their output. As a result, the market is witnessing a shift towards more sustainable and cost-effective production methods. The introduction of new electrolytic cell designs and materials is also contributing to higher yields and lower energy consumption. These technological advancements not only bolster the competitiveness of electrolytic iron producers but also align with the growing emphasis on sustainability within the industry.

Regulatory Support for Sustainable Practices

The Electrolytic Iron Market is witnessing a favorable regulatory environment that promotes sustainable practices. Governments across various regions are implementing policies aimed at reducing carbon emissions and encouraging the use of environmentally friendly materials. This regulatory support is likely to enhance the adoption of electrolytic iron, as it is often produced through processes that have a lower environmental impact compared to traditional iron production methods. Additionally, initiatives aimed at promoting recycling and the circular economy are expected to further bolster the market for electrolytic iron. As manufacturers align their operations with these regulations, the demand for electrolytic iron is anticipated to increase, positioning it as a preferred choice for sustainable production.