Regulatory Standards and Compliance

Regulatory standards and compliance requirements are becoming increasingly stringent, thereby driving the Electromagnetic and Radio Frequency Interference Coating for Electric Vehicles Market. Governments and regulatory bodies are implementing guidelines to ensure that electric vehicles meet specific electromagnetic compatibility (EMC) standards. These regulations are designed to minimize electromagnetic interference that could affect vehicle performance and safety. As of 2025, it is anticipated that compliance with these regulations will be mandatory for all new electric vehicle models, compelling manufacturers to invest in high-quality EMI and RFI coatings. This regulatory landscape not only enhances consumer safety but also fosters innovation within the industry, as companies strive to develop coatings that meet or exceed these evolving standards. The emphasis on compliance is likely to create a competitive advantage for manufacturers who can deliver superior coating solutions.

Increasing Electric Vehicle Adoption

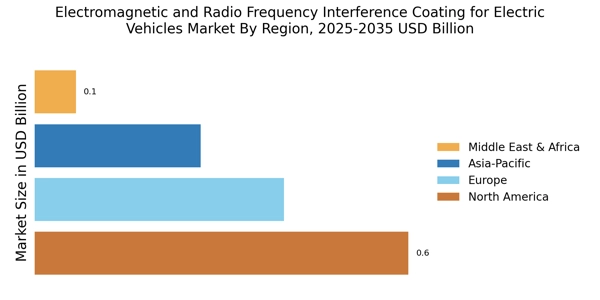

The rising adoption of electric vehicles (EVs) is a primary driver for the Electromagnetic and Radio Frequency Interference Coating for Electric Vehicles Market. As consumers and manufacturers shift towards EVs, the need for effective EMI and RFI coatings becomes more pronounced. In 2025, the number of electric vehicles on the road is projected to surpass 30 million units, indicating a robust growth trajectory. This surge necessitates advanced coatings to protect sensitive electronic components from interference, ensuring optimal performance and safety. The integration of sophisticated electronic systems in EVs, such as advanced driver-assistance systems (ADAS) and infotainment systems, further amplifies the demand for reliable coatings. Consequently, manufacturers are increasingly investing in innovative EMI and RFI solutions to meet the evolving needs of the electric vehicle sector.

Growing Focus on Vehicle Safety and Performance

The growing focus on vehicle safety and performance is a crucial driver for the Electromagnetic and Radio Frequency Interference Coating for Electric Vehicles Market. As electric vehicles become more prevalent, consumers are increasingly concerned about the reliability of electronic systems that govern critical functions such as braking, steering, and navigation. Effective EMI and RFI coatings play a vital role in ensuring that these systems operate without interference, thereby enhancing overall vehicle safety. In 2025, it is projected that the demand for high-performance coatings will rise as manufacturers seek to differentiate their products in a competitive market. This focus on safety and performance is likely to lead to increased investments in research and development, resulting in the introduction of innovative coating solutions that address the specific needs of electric vehicles.

Sustainability and Environmental Considerations

Sustainability and environmental considerations are increasingly influencing the Electromagnetic and Radio Frequency Interference Coating for Electric Vehicles Market. As the automotive sector shifts towards more sustainable practices, there is a growing demand for eco-friendly coating solutions that minimize environmental impact. Manufacturers are exploring bio-based and recyclable materials for EMI and RFI coatings, aligning with the broader trend of sustainability in electric vehicle production. By 2025, it is expected that a significant portion of the market will be driven by the need for coatings that not only provide effective electromagnetic shielding but also adhere to environmental regulations. This shift towards sustainable practices may encourage innovation in coating technologies, as companies strive to develop solutions that meet both performance and environmental standards.

Technological Advancements in Coating Solutions

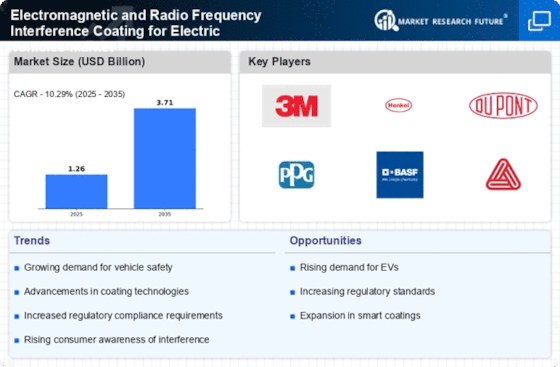

Technological advancements in coating solutions are significantly influencing the Electromagnetic and Radio Frequency Interference Coating for Electric Vehicles Market. Innovations in material science have led to the development of more effective and durable coatings that can withstand harsh environmental conditions while providing superior electromagnetic shielding. For instance, the introduction of nanotechnology in coating formulations has enhanced the performance characteristics of EMI and RFI coatings, making them lighter and more efficient. As of 2025, the market for advanced coating technologies is expected to grow at a compound annual growth rate (CAGR) of over 10%, driven by the increasing complexity of electronic systems in EVs. This trend suggests that manufacturers are likely to prioritize the adoption of cutting-edge coating technologies to ensure compliance with stringent industry standards and enhance vehicle reliability.