Rising Focus on Automotive Electronics

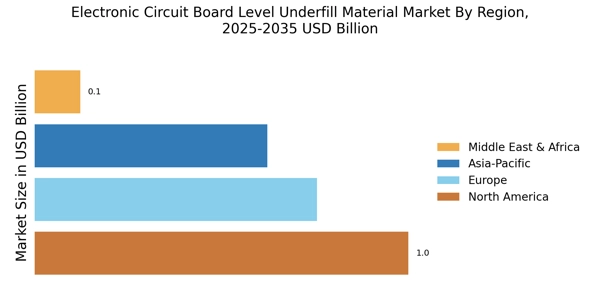

The Electronic Circuit Board Level Underfill Material Market is witnessing a notable increase in demand due to the rising focus on automotive electronics. As vehicles become more technologically advanced, incorporating features such as autonomous driving and advanced driver-assistance systems, the need for reliable underfill materials becomes critical. The automotive electronics market is projected to reach approximately 400 billion dollars by 2025, indicating a substantial growth opportunity for underfill materials. These materials are essential for ensuring the durability and reliability of electronic components in harsh automotive environments. Additionally, the shift towards electric vehicles further emphasizes the need for high-performance underfill materials that can withstand thermal and mechanical stresses. Therefore, the rising focus on automotive electronics is a key driver for the Electronic Circuit Board Level Underfill Material Market.

Growth of the Telecommunications Sector

The Electronic Circuit Board Level Underfill Material Market is positively impacted by the growth of the telecommunications sector. With the ongoing expansion of telecommunications infrastructure, particularly in the context of 5G technology, there is an increasing demand for high-performance circuit boards that require effective underfill materials. The telecommunications market is anticipated to grow significantly, with investments in 5G infrastructure expected to exceed 300 billion dollars by 2025. This growth necessitates the use of advanced underfill materials that can enhance the reliability and performance of circuit boards used in telecommunications equipment. As the industry evolves, the need for materials that can withstand the rigors of high-frequency applications becomes increasingly important. Thus, the growth of the telecommunications sector serves as a vital driver for the Electronic Circuit Board Level Underfill Material Market.

Advancements in Semiconductor Technology

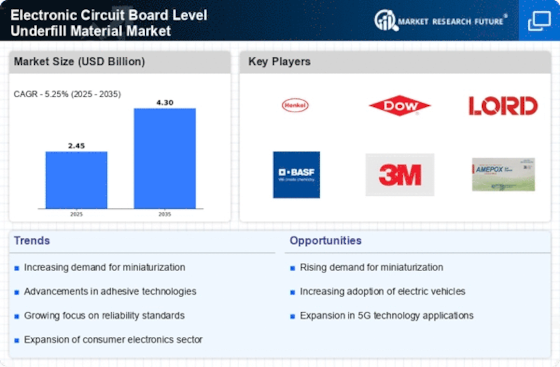

The Electronic Circuit Board Level Underfill Material Market is significantly influenced by advancements in semiconductor technology. As semiconductor devices evolve, they require more sophisticated underfill materials to meet the performance and reliability standards. The semiconductor market is expected to grow at a compound annual growth rate of around 8% through 2025, which suggests a corresponding increase in the demand for underfill materials. These materials play a crucial role in protecting sensitive components from environmental factors and mechanical stress, thereby enhancing the overall performance of semiconductor devices. Furthermore, the trend towards higher integration levels in semiconductor packaging necessitates the use of advanced underfill materials that can accommodate the unique challenges posed by these technologies. Consequently, advancements in semiconductor technology are likely to drive growth in the Electronic Circuit Board Level Underfill Material Market.

Increasing Demand for Consumer Electronics

The Electronic Circuit Board Level Underfill Material Market experiences a surge in demand driven by the growing consumer electronics sector. As devices become more compact and feature-rich, the need for reliable underfill materials to enhance durability and performance becomes paramount. In 2025, the consumer electronics market is projected to reach a valuation of approximately 1 trillion dollars, indicating a robust growth trajectory. This growth is likely to propel the demand for underfill materials, as manufacturers seek to ensure the longevity and reliability of their products. The integration of advanced technologies, such as 5G and IoT, further amplifies this demand, as these technologies necessitate high-performance circuit boards that can withstand thermal and mechanical stresses. Thus, the increasing consumer electronics demand significantly influences the Electronic Circuit Board Level Underfill Material Market.

Emerging Applications in Industrial Automation

The Electronic Circuit Board Level Underfill Material Market is experiencing growth due to emerging applications in industrial automation. As industries increasingly adopt automation technologies, the demand for reliable electronic components rises, necessitating the use of effective underfill materials. The industrial automation market is projected to grow at a compound annual growth rate of around 10% through 2025, indicating a robust demand for underfill materials. These materials are crucial for ensuring the durability and performance of electronic components used in automation systems, which often operate in challenging environments. Furthermore, the integration of smart technologies and IoT in industrial applications further drives the need for high-performance underfill materials. Consequently, the emergence of applications in industrial automation is a significant driver for the Electronic Circuit Board Level Underfill Material Market.