Diverse Application Range

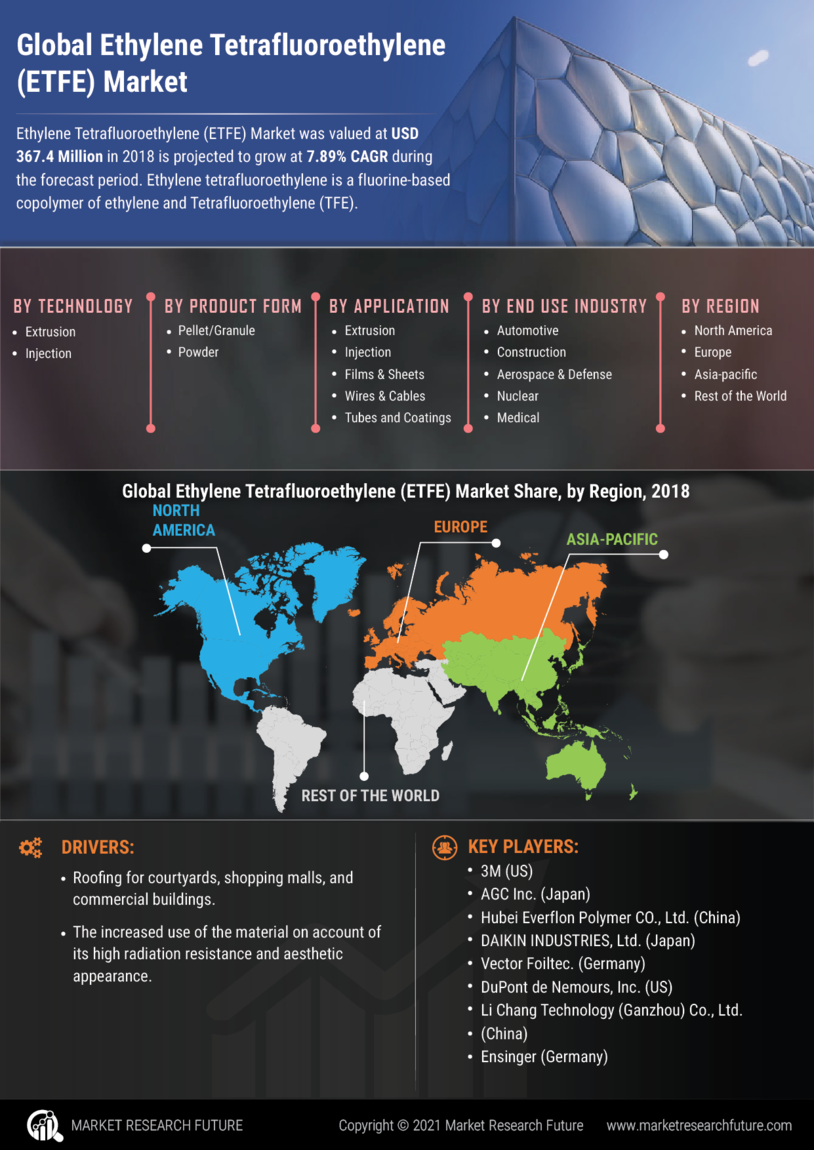

The versatility of Ethylene Tetrafluoroethylene is a crucial driver for the Global Ethylene Tetrafluoroethylene market Industry. ETFE is utilized across various sectors, including automotive, aerospace, and telecommunications, due to its unique properties such as high tensile strength and resistance to UV radiation. This wide application range allows ETFE to cater to diverse market needs, enhancing its appeal to manufacturers. As industries continue to seek high-performance materials, the demand for ETFE is expected to grow. The projected market value of 537.1 USD Million by 2035 reflects the increasing recognition of ETFE's capabilities across multiple sectors.

Market Growth Projections

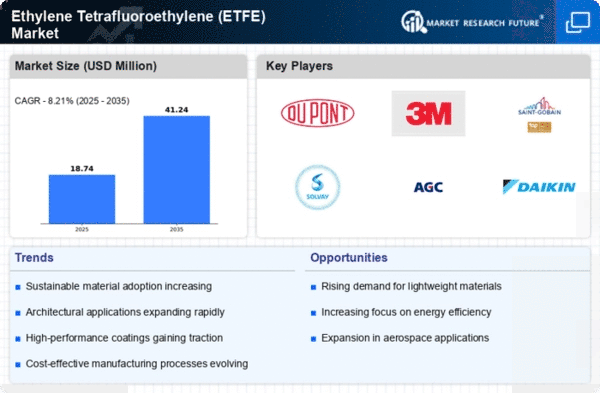

The Global Ethylene Tetrafluoroethylene market Industry is characterized by optimistic growth projections. With a market value expected to reach 180.6 USD Million in 2024 and a significant increase to 537.1 USD Million by 2035, the industry is on a positive trajectory. The anticipated CAGR of 10.42% from 2025 to 2035 highlights the robust demand for ETFE across various applications. This growth is driven by factors such as technological advancements, sustainability initiatives, and increasing construction activities. The market's expansion reflects the growing recognition of ETFE as a vital material in modern manufacturing and construction.

Sustainability Initiatives

Sustainability is becoming a pivotal driver in the Global Ethylene Tetrafluoroethylene market Industry. With increasing regulatory pressures and consumer preferences shifting towards eco-friendly products, manufacturers are focusing on sustainable practices. ETFE is known for its recyclability and lower environmental impact compared to traditional materials. This aligns with global efforts to reduce carbon footprints and promote sustainable manufacturing processes. As a result, the adoption of ETFE in various applications, including construction and automotive, is expected to rise. The market's projected growth to 537.1 USD Million by 2035 underscores the potential of sustainability as a key driver in the industry.

Growing Demand in Electronics

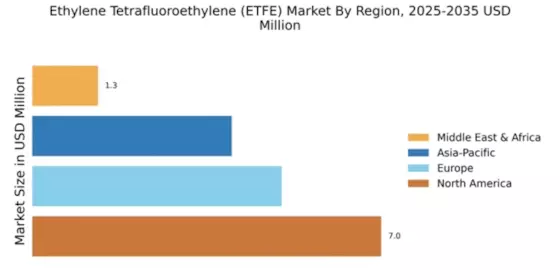

The Global Ethylene Tetrafluoroethylene market Industry is experiencing a surge in demand driven by the electronics sector. ETFE's excellent electrical insulation properties make it a preferred choice for various electronic components, including wires and connectors. As the global electronics market continues to expand, particularly in regions such as Asia-Pacific, the need for high-performance materials like ETFE is likely to increase. This trend is reflected in the projected market value of 180.6 USD Million in 2024, indicating a robust growth trajectory. The ongoing advancements in technology further bolster the demand for ETFE, as manufacturers seek materials that can withstand extreme conditions.

Advancements in Material Science

Innovations in material science are significantly influencing the Global Ethylene Tetrafluoroethylene market Industry. Researchers are continuously exploring new formulations and applications for ETFE, enhancing its properties such as chemical resistance and thermal stability. These advancements enable ETFE to be utilized in a broader range of industries, including aerospace and medical devices. The ongoing development of ETFE composites and blends is likely to open new avenues for market growth. As the industry evolves, the projected compound annual growth rate (CAGR) of 10.42% from 2025 to 2035 suggests a promising future for ETFE, driven by these scientific advancements.

Increasing Construction Activities

The Global Ethylene Tetrafluoroethylene market Industry is poised to benefit from the rising construction activities worldwide. ETFE's lightweight and durable nature makes it an ideal choice for architectural applications, such as roofing and facades. The trend towards modern and sustainable building designs is further propelling the demand for ETFE. Regions experiencing rapid urbanization, particularly in Asia and the Middle East, are likely to see increased adoption of ETFE in construction projects. This trend aligns with the market's anticipated growth, reaching 180.6 USD Million in 2024, as builders and architects seek innovative materials that offer both aesthetic and functional advantages.