Growth in Construction Activities

The expansion of construction activities across various sectors, including residential, commercial, and industrial, is likely to propel the Extruded Polystyrene Insulation Material Market. As urbanization accelerates, the need for new buildings and infrastructure increases, leading to a higher demand for effective insulation solutions. In recent years, the construction sector has witnessed a resurgence, with investments in new projects reaching unprecedented levels. This growth is expected to continue, with estimates suggesting that the construction industry could see a growth rate of around 4% annually. Consequently, the demand for extruded polystyrene insulation, which offers durability and moisture resistance, is anticipated to rise, further solidifying its position in the market.

Rising Demand for Energy Efficiency

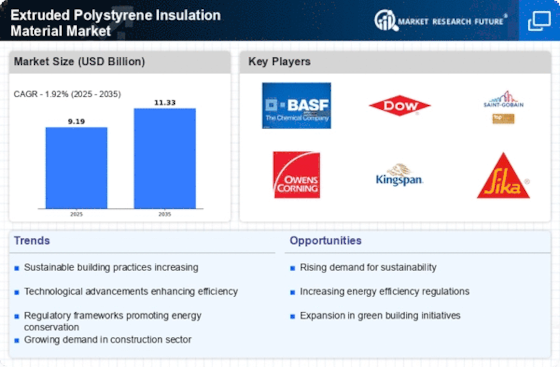

The increasing emphasis on energy efficiency in construction and renovation projects appears to be a primary driver for the Extruded Polystyrene Insulation Material Market. As energy costs continue to rise, builders and homeowners are seeking materials that provide superior insulation properties. Extruded polystyrene, known for its high thermal resistance, is often preferred for its ability to reduce energy consumption. According to recent data, the insulation market is projected to grow at a compound annual growth rate of approximately 5% over the next few years, indicating a robust demand for energy-efficient materials. This trend is likely to bolster the market for extruded polystyrene insulation, as it aligns with the broader goals of reducing carbon footprints and enhancing building performance.

Technological Innovations in Insulation

Technological advancements in insulation materials are playing a crucial role in shaping the Extruded Polystyrene Insulation Material Market. Innovations such as improved manufacturing processes and enhanced product formulations are leading to the development of more efficient and effective insulation solutions. For instance, the introduction of new additives and composite materials has enhanced the performance characteristics of extruded polystyrene, making it more appealing to consumers. Market data indicates that the insulation materials segment is evolving rapidly, with a projected increase in the adoption of advanced insulation technologies. This trend suggests that manufacturers who invest in research and development may gain a competitive edge, thereby driving the growth of the extruded polystyrene insulation market.

Regulatory Support for Energy-Efficient Materials

The implementation of stringent building codes and regulations aimed at promoting energy efficiency is likely to influence the Extruded Polystyrene Insulation Material Market positively. Governments are increasingly mandating the use of high-performance insulation materials in new constructions and renovations to meet energy efficiency standards. This regulatory environment encourages builders and architects to select materials that comply with these standards, thereby boosting the demand for extruded polystyrene insulation. Recent legislative measures have been introduced in various regions, promoting the use of sustainable building practices. As a result, the extruded polystyrene insulation market is expected to benefit from these regulatory frameworks, which are designed to enhance energy conservation and reduce environmental impact.

Increased Awareness of Sustainable Building Practices

The growing awareness of sustainable building practices among consumers and industry professionals is emerging as a significant driver for the Extruded Polystyrene Insulation Material Market. As stakeholders become more conscious of environmental issues, there is a marked shift towards materials that not only provide insulation but also contribute to sustainability goals. Extruded polystyrene insulation, with its recyclable properties and low environmental impact during production, aligns well with these values. Market Research Future indicates that the demand for sustainable building materials is on the rise, with projections suggesting a growth rate of approximately 6% in the coming years. This trend is likely to encourage manufacturers to focus on eco-friendly practices, further enhancing the appeal of extruded polystyrene insulation in the market.