Rising Demand for Sustainable Packaging

The Global Extrusion Coatings Market Industry experiences a notable increase in demand for sustainable packaging solutions. As consumers become more environmentally conscious, manufacturers are compelled to adopt eco-friendly materials. Extrusion coatings, which enhance the recyclability of packaging, align with this trend. In 2024, the market is valued at 3.28 USD Billion, reflecting a shift towards sustainable practices. Companies are increasingly utilizing extrusion coatings to improve the performance of biodegradable materials, thereby reducing their carbon footprint. This transition not only meets consumer expectations but also complies with stringent regulations aimed at minimizing environmental impact.

Growth in Automotive and Construction Sectors

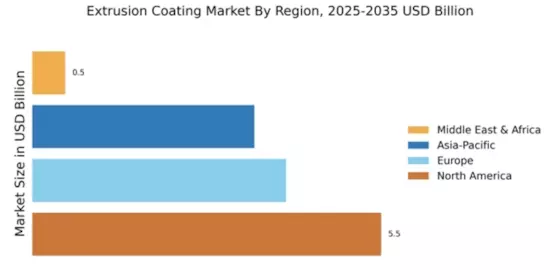

The Global Extrusion Coatings Market Industry benefits from the expansion of the automotive and construction sectors. These industries increasingly utilize extrusion coatings for their protective and aesthetic properties. In automotive applications, coatings are employed to enhance the durability of components and improve surface finishes. Similarly, in construction, extrusion coatings are used to protect materials from corrosion and weathering. The robust growth in these sectors is expected to contribute significantly to market expansion, with a projected compound annual growth rate of 8.94% from 2025 to 2035. This growth underscores the versatility and importance of extrusion coatings in various applications.

Technological Advancements in Coating Processes

Technological innovations play a pivotal role in shaping the Global Extrusion Coatings Market Industry. Advanced extrusion techniques enhance the efficiency and quality of coatings, leading to improved product performance. Innovations such as multi-layer extrusion and the development of high-performance polymers are becoming increasingly prevalent. These advancements allow for better adhesion, durability, and resistance to various environmental factors. As a result, manufacturers can produce coatings that meet diverse application requirements across industries. The ongoing evolution of technology is expected to drive market growth, with projections indicating a market value of 8.41 USD Billion by 2035.

Expanding Applications Across Diverse Industries

The Global Extrusion Coatings Market Industry is witnessing an expansion of applications across various sectors, including food packaging, electronics, and textiles. The versatility of extrusion coatings allows them to be tailored for specific uses, enhancing their appeal to manufacturers. In food packaging, for instance, extrusion coatings provide moisture barriers that extend shelf life. In electronics, they offer protection against environmental factors. This broad applicability is driving market growth as industries seek efficient solutions to meet their unique needs. The increasing adoption of extrusion coatings in diverse applications is expected to sustain market momentum in the coming years.

Increasing Regulatory Support for Coating Standards

Regulatory frameworks are becoming more supportive of high-quality coating standards, positively impacting the Global Extrusion Coatings Market Industry. Governments worldwide are implementing stringent regulations to ensure product safety and environmental compliance. These regulations encourage manufacturers to adopt advanced extrusion coating technologies that meet or exceed established standards. As a result, companies are investing in research and development to create innovative coatings that comply with these regulations. This trend not only enhances product quality but also fosters consumer trust, ultimately driving market growth. The emphasis on compliance is likely to shape the industry's future landscape.