Increasing Demand for Energy Efficiency

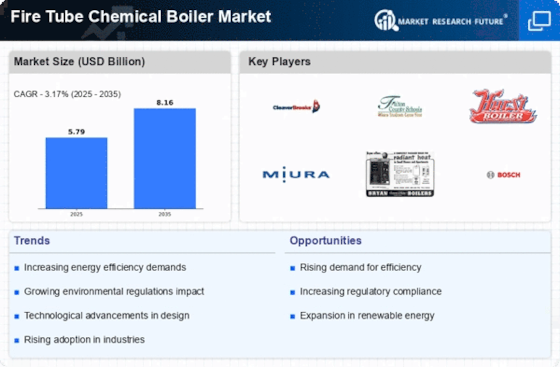

The Fire Tube Chemical Boiler Market is experiencing a notable surge in demand for energy-efficient solutions. As industries strive to reduce operational costs and enhance productivity, the adoption of fire tube boilers, known for their efficiency, is on the rise. These boilers typically exhibit higher thermal efficiency compared to their water tube counterparts, which can lead to significant energy savings. According to recent data, the energy efficiency of fire tube boilers can reach up to 90%, making them an attractive option for various sectors. This trend is likely to continue as companies increasingly prioritize sustainability and cost-effectiveness in their operations.

Technological Innovations in Boiler Design

The Fire Tube Chemical Boiler Market is benefiting from ongoing technological innovations in boiler design. Manufacturers are increasingly integrating advanced technologies such as automation and smart controls into fire tube boilers, enhancing their operational efficiency and user-friendliness. These innovations not only improve performance but also facilitate predictive maintenance, reducing downtime and operational costs. The market is witnessing a shift towards more sophisticated boiler systems that can adapt to varying operational demands. As these technologies continue to evolve, they are expected to attract more users to fire tube boilers, thereby expanding the market.

Expansion of Chemical Processing Industries

The Fire Tube Chemical Boiler Market is poised for growth due to the expansion of chemical processing industries. As these industries continue to evolve, the demand for reliable and efficient heating solutions becomes paramount. Fire tube boilers are particularly well-suited for chemical processing applications, where consistent temperature control is critical. Recent statistics indicate that the chemical manufacturing sector is projected to grow at a compound annual growth rate of approximately 4% over the next few years. This growth is likely to drive the demand for fire tube boilers, as they provide the necessary thermal efficiency and reliability required in chemical processes.

Regulatory Compliance and Environmental Standards

The Fire Tube Chemical Boiler Market is significantly influenced by stringent regulatory compliance and environmental standards. Governments worldwide are implementing regulations aimed at reducing emissions and promoting cleaner technologies. Fire tube boilers, which can be designed to meet these standards, are becoming essential for industries that require compliance with environmental regulations. The market is projected to grow as manufacturers innovate to produce boilers that not only meet but exceed these standards. This shift towards compliance is expected to drive investments in fire tube boiler technology, thereby enhancing market growth and sustainability.

Rising Industrialization and Infrastructure Development

The Fire Tube Chemical Boiler Market is experiencing growth driven by rising industrialization and infrastructure development. As countries invest in infrastructure projects, the demand for energy and heating solutions increases correspondingly. Fire tube boilers are favored in various industrial applications due to their robust design and efficiency. The construction and manufacturing sectors are particularly reliant on these boilers for their heating needs. Recent projections suggest that infrastructure spending will continue to rise, potentially boosting the fire tube boiler market as industries seek reliable and efficient heating solutions to support their operations.