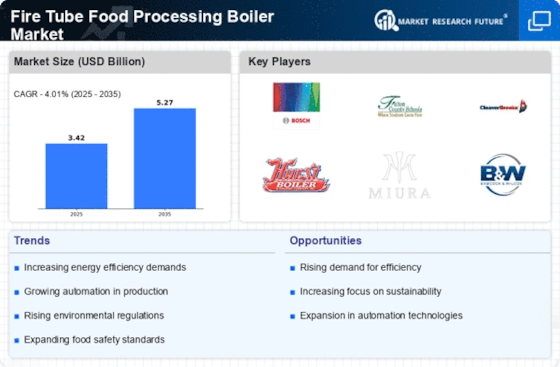

Rising Demand for Processed Foods

The increasing demand for processed foods is a primary driver of the Fire Tube Food Processing Boiler Market. As consumer preferences shift towards convenience and ready-to-eat meals, food manufacturers are compelled to enhance production efficiency. This trend is reflected in the projected growth of the processed food sector, which is expected to reach a valuation of over 3 trillion USD by 2025. Consequently, food processing companies are investing in advanced boiler systems to meet production demands while ensuring quality and safety. Fire tube boilers, known for their efficiency and reliability, are particularly favored in this context, as they provide the necessary steam and heat for various food processing applications. This growing market demand is likely to propel the Fire Tube Food Processing Boiler Market forward.

Energy Efficiency and Cost Savings

Energy efficiency is becoming increasingly critical in the food processing sector, driving the Fire Tube Food Processing Boiler Market. With rising energy costs, food manufacturers are seeking solutions that not only reduce operational expenses but also minimize environmental impact. Fire tube boilers are recognized for their high thermal efficiency, often exceeding 80%, which translates into significant cost savings over time. The ability to utilize various fuel types, including natural gas and biomass, further enhances their appeal. As energy regulations tighten, the adoption of energy-efficient technologies is expected to accelerate, positioning fire tube boilers as a preferred choice among food processors. This trend indicates a robust growth trajectory for the Fire Tube Food Processing Boiler Market.

Growing Focus on Food Safety Standards

The growing focus on food safety standards is a significant driver of the Fire Tube Food Processing Boiler Market. Regulatory bodies worldwide are implementing stricter guidelines to ensure the safety and quality of food products. Fire tube boilers play a crucial role in maintaining hygiene and safety during food processing, as they provide consistent and reliable steam for sterilization and cooking processes. Compliance with food safety regulations necessitates the use of high-quality boiler systems that can withstand rigorous operational demands. As food manufacturers invest in upgrading their facilities to meet these standards, the demand for fire tube boilers is likely to increase, thereby enhancing the growth prospects of the Fire Tube Food Processing Boiler Market.

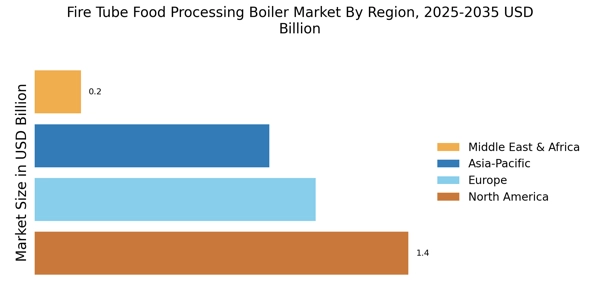

Expansion of the Food Processing Sector

The expansion of the food processing sector is a key driver of the Fire Tube Food Processing Boiler Market. As economies develop and urbanization accelerates, there is a notable increase in food processing activities to cater to the growing population. This expansion is evident in various regions, where investments in food processing infrastructure are on the rise. For instance, the food processing industry is projected to grow at a compound annual growth rate of over 5% in the coming years. Fire tube boilers are essential in this context, providing the necessary heat and steam for diverse applications, from cooking to drying. As the food processing sector continues to evolve, the demand for efficient and reliable fire tube boilers is expected to surge, driving the Fire Tube Food Processing Boiler Market.

Technological Innovations in Boiler Design

Technological innovations are reshaping the Fire Tube Food Processing Boiler Market, as manufacturers strive to enhance performance and reliability. Recent advancements in boiler design, such as improved heat exchange systems and automated controls, are enabling food processors to achieve higher efficiency and lower emissions. The integration of smart technologies, including IoT and predictive maintenance, is also gaining traction, allowing for real-time monitoring and optimization of boiler operations. These innovations not only improve operational efficiency but also ensure compliance with stringent environmental regulations. As food processing companies increasingly prioritize modernization, the demand for advanced fire tube boilers is expected to rise, further propelling the Fire Tube Food Processing Boiler Market.

.png)