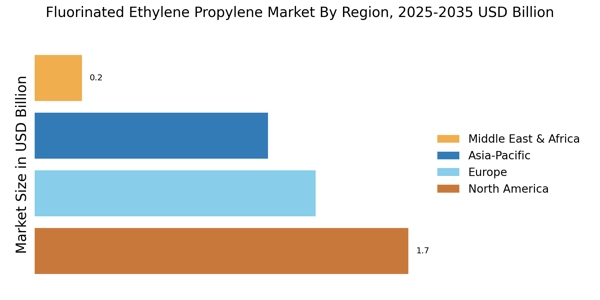

Growth in Renewable Energy Sector

The Fluorinated Ethylene Propylene Market is poised to benefit from the rapid growth in the renewable energy sector. As the world shifts towards sustainable energy solutions, the demand for high-performance materials in solar panels and wind turbines is increasing. FEP is particularly valued for its excellent electrical insulation properties and resistance to UV radiation, making it suitable for various renewable energy applications. The renewable energy market is expected to expand significantly, with investments projected to reach trillions of dollars in the coming years. This trend suggests that the Fluorinated Ethylene Propylene Market will likely see increased demand as manufacturers seek reliable materials that enhance the efficiency and longevity of renewable energy systems.

Advancements in Medical Technology

The Fluorinated Ethylene Propylene Market is benefiting from advancements in medical technology, where FEP is increasingly utilized in various applications. Its biocompatibility and resistance to sterilization processes make it suitable for medical devices, including catheters and surgical instruments. The medical device market is anticipated to grow significantly, driven by an aging population and increasing healthcare needs. This growth could lead to a heightened demand for high-quality materials like FEP that ensure safety and reliability in medical applications. As the medical technology sector evolves, the Fluorinated Ethylene Propylene Market is likely to see increased opportunities for growth and innovation.

Rising Demand in Chemical Processing

The Fluorinated Ethylene Propylene Market is witnessing a rise in demand driven by the chemical processing sector. FEP's exceptional chemical resistance and thermal stability make it an ideal choice for various applications, including piping, valves, and seals in chemical plants. As the global chemical industry continues to expand, with a projected growth rate of around 3% annually, the need for high-performance materials like FEP is likely to increase. This growth is attributed to the ongoing development of new chemical processes and the need for materials that can withstand aggressive chemicals. Therefore, the Fluorinated Ethylene Propylene Market is expected to thrive as it caters to the evolving needs of the chemical processing sector.

Expansion of Telecommunications Infrastructure

The Fluorinated Ethylene Propylene Market is experiencing growth due to the expansion of telecommunications infrastructure. With the increasing demand for high-speed internet and advanced communication technologies, FEP is becoming a preferred material for insulation in cables and connectors. The telecommunications sector is projected to grow at a robust pace, driven by the proliferation of 5G technology and the Internet of Things (IoT). This expansion necessitates materials that can withstand environmental stressors while maintaining performance. Consequently, the Fluorinated Ethylene Propylene Market is likely to benefit from this trend, as manufacturers seek reliable materials to support the evolving telecommunications landscape.

Increasing Applications in Automotive Industry

The Fluorinated Ethylene Propylene Market is experiencing a notable surge in demand due to its increasing applications in the automotive sector. As manufacturers seek materials that can withstand extreme temperatures and harsh environments, FEP emerges as a preferred choice for insulation and protective coatings. The automotive industry is projected to grow at a compound annual growth rate of approximately 4% over the next few years, which could further drive the demand for FEP. This material's unique properties, such as chemical resistance and low friction, make it ideal for various automotive components, including wiring and fuel systems. Consequently, the expansion of the automotive sector is likely to bolster the Fluorinated Ethylene Propylene Market, as manufacturers prioritize performance and durability in their products.