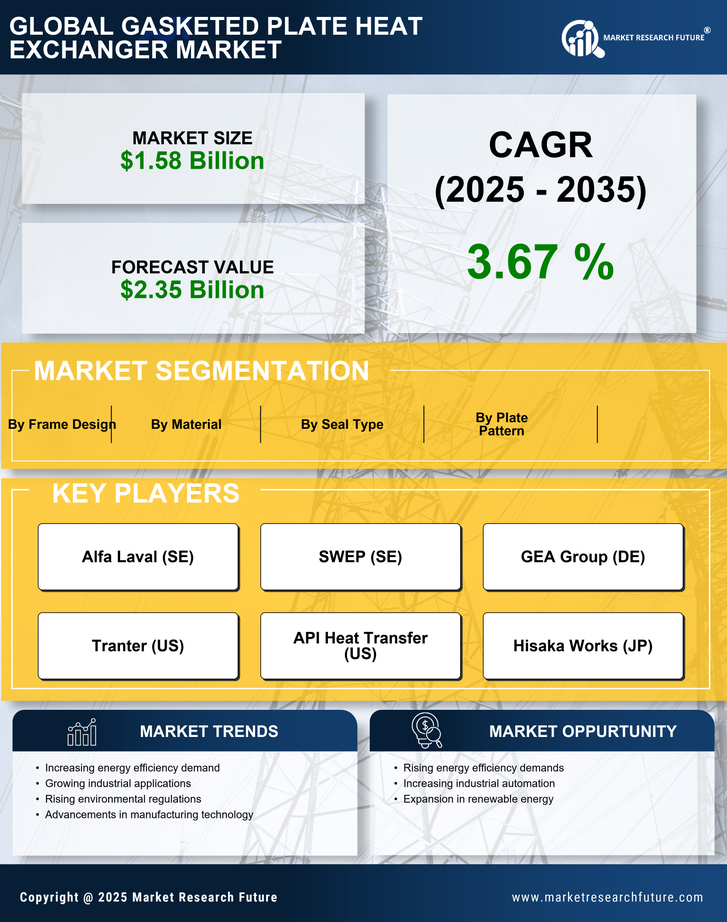

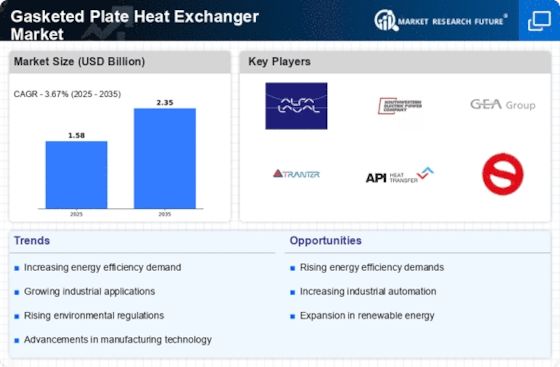

Increasing Demand for Energy Efficiency

The Gasketed Plate Heat Exchanger Market is experiencing a notable surge in demand for energy-efficient solutions. Industries are increasingly focusing on reducing energy consumption and operational costs, which has led to a heightened interest in heat exchangers that optimize thermal performance. According to recent data, energy-efficient heat exchangers can reduce energy costs by up to 30%, making them an attractive option for various sectors, including food and beverage, chemical processing, and HVAC. This trend is likely to continue as companies strive to meet regulatory requirements and sustainability goals, further propelling the growth of the Gasketed Plate Heat Exchanger Market.

Expansion of the Food and Beverage Sector

The Gasketed Plate Heat Exchanger Market is benefiting from the expansion of the food and beverage sector, which requires efficient thermal management solutions. As consumer demand for processed and packaged foods rises, manufacturers are increasingly investing in advanced heat exchange technologies to ensure product quality and safety. Gasketed plate heat exchangers are particularly suited for this industry due to their ability to handle varying temperatures and pressures while maintaining hygiene standards. Recent market data suggests that the food and beverage sector is expected to grow at a CAGR of 4.5% over the next few years, further enhancing the demand for gasketed plate heat exchangers.

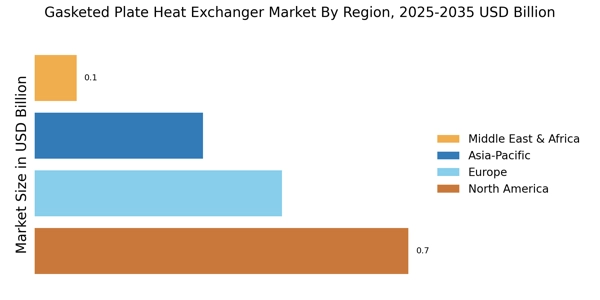

Rising Industrialization and Urbanization

The Gasketed Plate Heat Exchanger Market is poised for growth due to the rapid pace of industrialization and urbanization. As countries develop, there is an increasing need for efficient heating and cooling systems in various sectors, including manufacturing, construction, and energy production. The expansion of urban areas necessitates advanced infrastructure, which often incorporates heat exchangers for improved energy management. Market data indicates that the industrial sector is projected to grow at a CAGR of 5% over the next five years, driving demand for innovative heat exchange solutions. This trend underscores the critical role of gasketed plate heat exchangers in modern industrial applications.

Technological Innovations in Heat Exchange Solutions

Technological advancements are significantly influencing the Gasketed Plate Heat Exchanger Market. Innovations such as enhanced plate designs, improved gasket materials, and advanced manufacturing techniques are leading to more efficient and durable heat exchangers. These developments not only enhance thermal performance but also extend the lifespan of the equipment, reducing maintenance costs. Recent studies suggest that the introduction of new technologies could increase the efficiency of gasketed plate heat exchangers by up to 20%. As industries seek to leverage these advancements, the market is likely to witness a robust growth trajectory, driven by the demand for cutting-edge heat exchange solutions.

Growing Focus on Sustainability and Environmental Regulations

The Gasketed Plate Heat Exchanger Market is increasingly influenced by the global emphasis on sustainability and stringent environmental regulations. Industries are under pressure to adopt eco-friendly practices, which includes the implementation of energy-efficient systems that minimize waste and reduce carbon footprints. The adoption of gasketed plate heat exchangers aligns with these sustainability goals, as they are designed to maximize heat recovery and minimize energy loss. Market analysis indicates that companies investing in sustainable technologies are likely to see a return on investment through reduced energy costs and compliance with environmental standards, thereby driving the growth of the Gasketed Plate Heat Exchanger Market.