Growth in Renewable Energy Sector

The Plate Tube Heat Exchanger Market is poised to benefit from the rapid growth in the renewable energy sector. As countries and companies invest heavily in renewable energy sources such as solar, wind, and bioenergy, the need for efficient heat exchange systems becomes increasingly critical. Plate tube heat exchangers play a vital role in various renewable energy applications, including biomass energy production and geothermal systems. The ability of these exchangers to operate efficiently under varying conditions makes them suitable for the dynamic nature of renewable energy processes. As the shift towards sustainable energy solutions continues, the Plate Tube Heat Exchanger Market is likely to see a surge in demand, driven by the need for effective thermal management in renewable energy systems.

Regulatory Compliance and Standards

The Plate Tube Heat Exchanger Market is significantly influenced by stringent regulatory compliance and standards aimed at enhancing safety and environmental sustainability. Governments and regulatory bodies are increasingly mandating the use of efficient heat exchange systems to minimize energy consumption and reduce greenhouse gas emissions. Compliance with these regulations often necessitates the adoption of advanced technologies, such as plate tube heat exchangers, which offer improved performance and lower environmental impact. As industries strive to meet these regulatory requirements, the demand for plate tube heat exchangers is expected to rise. This trend not only supports the growth of the Plate Tube Heat Exchanger Market but also encourages manufacturers to innovate and develop more efficient products.

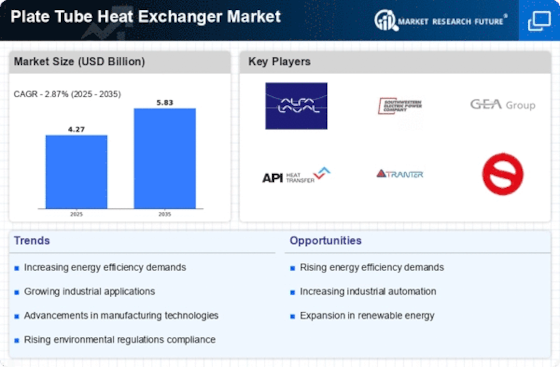

Rising Demand for Energy Efficiency

The Plate Tube Heat Exchanger Market is experiencing a notable increase in demand for energy-efficient solutions. Industries are increasingly focusing on reducing energy consumption and operational costs, which has led to a surge in the adoption of plate tube heat exchangers. These systems are known for their superior heat transfer capabilities, which can enhance energy efficiency by up to 30% compared to traditional heat exchangers. As energy prices continue to rise, the need for efficient thermal management solutions becomes more pressing. This trend is particularly evident in sectors such as chemical processing, oil and gas, and HVAC, where energy efficiency is paramount. The Plate Tube Heat Exchanger Market is thus positioned to benefit from this growing emphasis on sustainability and cost-effectiveness.

Expansion of Industrial Applications

The Plate Tube Heat Exchanger Market is witnessing an expansion in its applications across various industrial sectors. Industries such as food and beverage, pharmaceuticals, and power generation are increasingly utilizing plate tube heat exchangers for their versatility and efficiency. For instance, in the food and beverage sector, these heat exchangers are employed for pasteurization and cooling processes, ensuring product safety and quality. The pharmaceutical industry also relies on these systems for precise temperature control during production. According to recent data, the food and beverage sector alone accounts for a significant share of the market, indicating a robust growth trajectory. This diversification of applications is likely to drive further innovation and investment within the Plate Tube Heat Exchanger Market.

Technological Innovations in Heat Exchange Solutions

The Plate Tube Heat Exchanger Market is benefiting from ongoing technological innovations that enhance the performance and efficiency of heat exchange solutions. Recent advancements in materials and design have led to the development of more compact and efficient plate tube heat exchangers. These innovations allow for better heat transfer rates and reduced pressure drops, which can significantly improve overall system efficiency. Furthermore, the integration of smart technologies, such as IoT and automation, is transforming how these systems operate, enabling real-time monitoring and optimization. As industries seek to modernize their operations, the demand for technologically advanced heat exchangers is likely to grow, positioning the Plate Tube Heat Exchanger Market for sustained expansion.