Advancements in Imaging Technologies

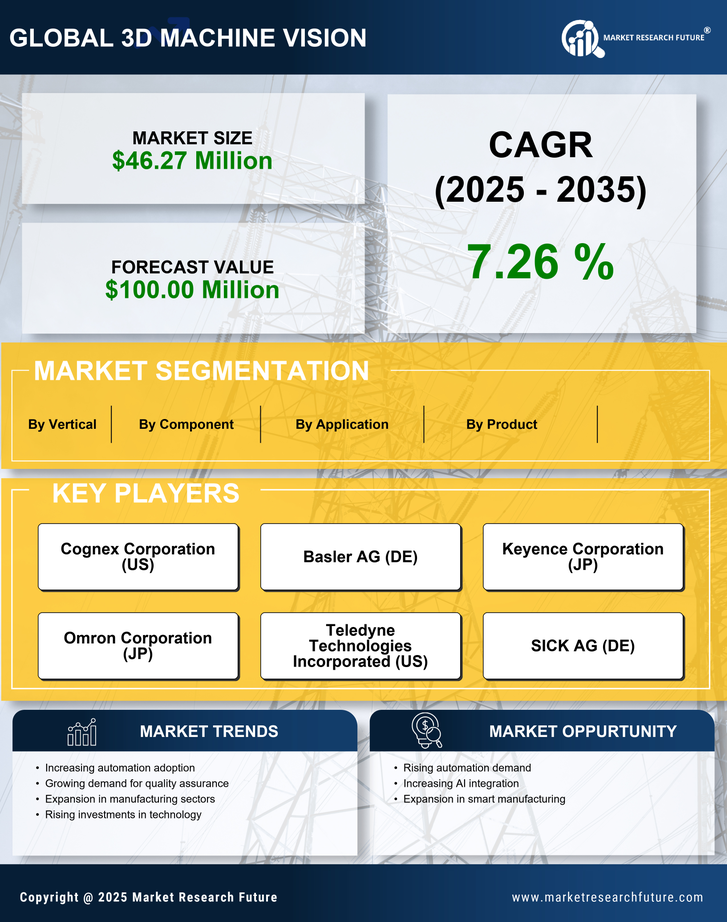

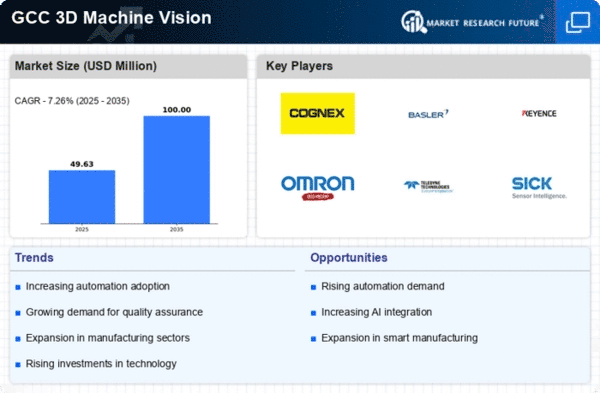

Technological advancements in imaging technologies are driving innovation within the 3d machine-vision market. The development of high-resolution cameras and sophisticated algorithms has enhanced the capabilities of machine-vision systems, allowing for more accurate and efficient inspections. In the GCC, industries are increasingly adopting these advanced imaging solutions to improve quality control processes. The market for imaging technologies is anticipated to grow at a CAGR of 11% from 2025 to 2030, reflecting the increasing reliance on high-quality imaging in various applications. As companies seek to leverage these advancements, the integration of cutting-edge imaging technologies into 3d machine-vision systems is likely to become more prevalent.

Growing Focus on Safety and Compliance

The emphasis on safety and compliance within industrial environments is increasingly shaping the 3d machine-vision market. Companies in the GCC are prioritizing the implementation of technologies that ensure adherence to safety regulations and quality standards. 3d machine-vision systems play a pivotal role in monitoring processes and identifying potential hazards, thereby enhancing workplace safety. The market for safety compliance technologies is projected to expand significantly, with estimates suggesting a growth rate of around 10% annually. As organizations strive to mitigate risks and enhance operational safety, the demand for 3d machine-vision solutions is expected to rise correspondingly.

Rising Demand for Precision Engineering

The 3d machine-vision market is experiencing a notable surge in demand for precision engineering across various sectors, particularly in manufacturing and construction. This demand is driven by the need for enhanced accuracy in production processes, which is essential for maintaining competitive advantage. In the GCC region, industries are increasingly adopting advanced technologies to ensure that their products meet stringent quality standards. The market for precision engineering is projected to grow at a CAGR of approximately 12% from 2025 to 2030, indicating a robust expansion. As companies strive to minimize errors and improve efficiency, the integration of 3d machine-vision systems becomes crucial, thereby propelling the market forward.

Increased Investment in Smart Manufacturing

Investment in smart manufacturing technologies is a key driver for the 3d machine-vision market. The GCC region is witnessing a shift towards Industry 4.0, characterized by the integration of IoT, AI, and advanced analytics into manufacturing processes. This transition is fostering a demand for 3d machine-vision systems that can provide real-time data and insights, thereby optimizing production efficiency. Reports indicate that the smart manufacturing market in the GCC is expected to grow at a CAGR of 15% over the next five years. As manufacturers seek to enhance productivity and reduce operational costs, the adoption of 3d machine-vision technology is likely to accelerate, further propelling market growth.

Expansion of Robotics in Industrial Applications

The integration of robotics within industrial applications is significantly influencing the 3d machine-vision market. As automation becomes more prevalent, the need for sophisticated vision systems that can guide robotic operations is paramount. In the GCC, sectors such as oil and gas, manufacturing, and logistics are increasingly utilizing robotic systems equipped with 3d machine-vision capabilities. This trend is expected to drive market growth, with estimates suggesting that the robotics market in the region could reach $5 billion by 2027. The synergy between robotics and 3d machine-vision technology enhances operational efficiency and accuracy, making it a vital component of modern industrial processes.