Rising Demand for Automation

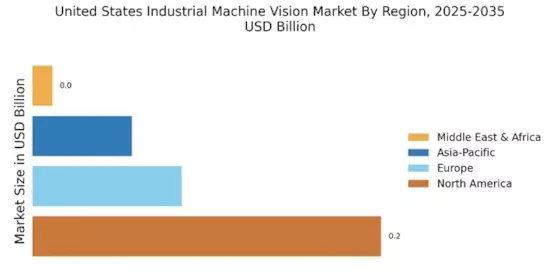

The US Industrial Machine Vision Market is experiencing a notable surge in demand for automation across various sectors. Industries such as manufacturing, automotive, and electronics are increasingly adopting machine vision systems to enhance operational efficiency and reduce labor costs. According to recent data, the market for industrial automation in the US is projected to reach approximately 200 billion USD by 2026. This trend is driven by the need for precision and speed in production processes, where machine vision plays a critical role in quality control and inspection. As companies strive to maintain competitiveness, the integration of machine vision technology becomes essential, thereby propelling the growth of the US Industrial Machine Vision Market.

Government Initiatives and Funding

Government initiatives aimed at promoting advanced manufacturing technologies are positively impacting the US Industrial Machine Vision Market. Various federal and state programs are providing funding and support for the adoption of automation and machine vision systems. These initiatives are designed to enhance the competitiveness of US manufacturers in the global market. For instance, the Manufacturing USA program focuses on fostering innovation and collaboration among industry stakeholders. As these government efforts continue to evolve, they are likely to stimulate investment in machine vision technologies, thereby accelerating growth within the US Industrial Machine Vision Market.

Increased Focus on Quality Control

Quality control remains a paramount concern for manufacturers in the US Industrial Machine Vision Market. The need to meet stringent quality standards and reduce defects is pushing companies to invest in machine vision systems. These systems provide real-time monitoring and inspection capabilities, ensuring that products meet required specifications. The market for quality control solutions is projected to grow significantly, with machine vision systems playing a pivotal role in this transformation. As industries face increasing pressure to deliver high-quality products, the adoption of machine vision technology is expected to rise, thereby bolstering the US Industrial Machine Vision Market.

Advancements in Imaging Technologies

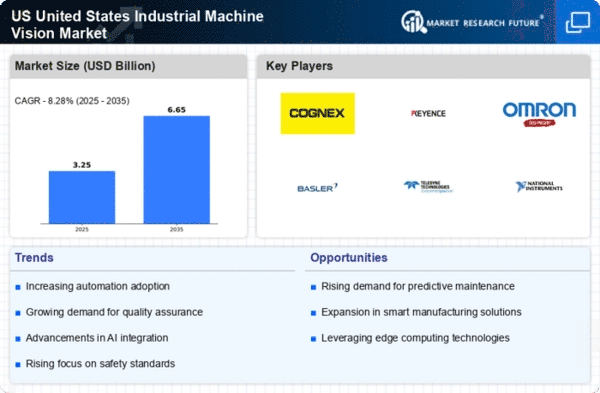

Technological advancements in imaging technologies are significantly influencing the US Industrial Machine Vision Market. Innovations such as 3D imaging, hyperspectral imaging, and high-resolution cameras are enhancing the capabilities of machine vision systems. These advancements allow for more accurate and detailed inspections, which are crucial in industries like pharmaceuticals and food processing. The market for imaging technologies is expected to grow at a compound annual growth rate (CAGR) of around 10% over the next few years. As these technologies become more accessible and affordable, their adoption in the US Industrial Machine Vision Market is likely to increase, further driving market growth.

Growth of E-commerce and Retail Automation

The rapid growth of e-commerce is reshaping the landscape of the US Industrial Machine Vision Market. Retailers are increasingly automating their operations to enhance efficiency and improve customer experience. Machine vision systems are being utilized for inventory management, order fulfillment, and quality assurance in warehouses. The e-commerce sector is projected to reach over 1 trillion USD in sales by 2026, driving the demand for automation solutions. This trend indicates a robust opportunity for machine vision technology to streamline processes and reduce operational costs, thereby contributing to the expansion of the US Industrial Machine Vision Market.