Supportive Regulatory Environment

A supportive regulatory environment is emerging as a key driver for the viral vectors-and-plasmid-dna-manufacturing market. Regulatory agencies in the GCC are increasingly recognizing the importance of gene therapies and are working to establish clear guidelines that facilitate the development and commercialization of these products. This proactive approach not only encourages investment in research and development but also fosters collaboration between industry stakeholders. As regulatory frameworks become more streamlined, companies are likely to experience reduced time-to-market for their products, which is essential in a rapidly evolving field. Furthermore, the establishment of regulatory incentives for biomanufacturing in the GCC could potentially enhance the attractiveness of the region for international players. Thus, the viral vectors-and-plasmid-dna-manufacturing market stands to gain from this evolving landscape, as it promotes innovation and growth.

Rising Demand for Advanced Therapeutics

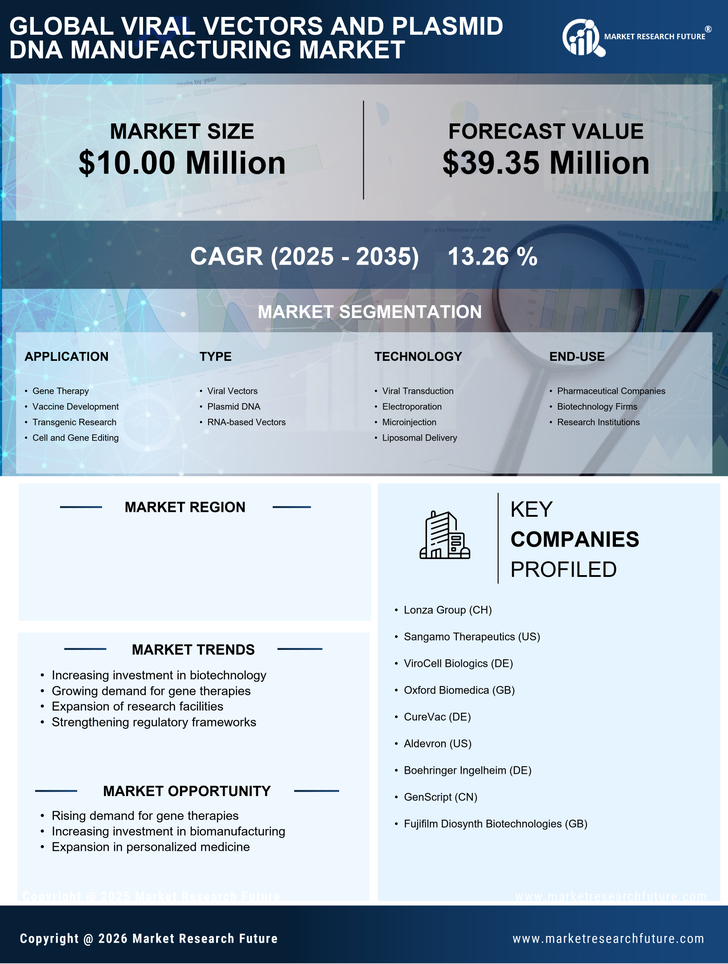

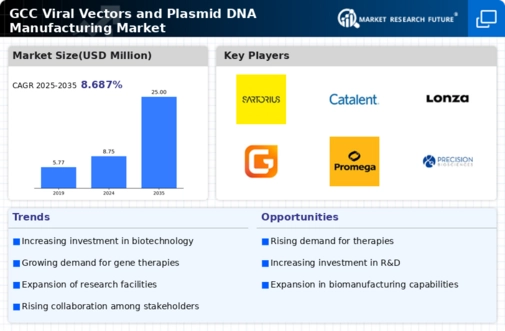

The viral vectors-and-plasmid-dna-manufacturing market is experiencing a notable surge in demand for advanced therapeutics, particularly in the GCC region. This demand is largely driven by the increasing prevalence of genetic disorders and chronic diseases, which necessitate innovative treatment solutions. As healthcare providers and pharmaceutical companies seek to develop more effective therapies, the reliance on viral vectors and plasmid DNA for gene delivery systems becomes paramount. Market data indicates that the GCC biopharmaceutical sector is projected to grow at a CAGR of approximately 8% over the next five years, further emphasizing the need for robust manufacturing capabilities in this domain. Consequently, the viral vectors-and-plasmid-dna-manufacturing market is positioned to benefit significantly from this trend, as it aligns with the broader shift towards personalized medicine and targeted therapies.

Increased Focus on Research and Development

An increased focus on research and development (R&D) is significantly influencing the viral vectors-and-plasmid-dna-manufacturing market. In the GCC, both public and private sectors are investing heavily in R&D initiatives aimed at advancing gene therapy technologies. This emphasis on innovation is driven by the need to address unmet medical needs and improve patient outcomes. As research institutions collaborate with industry players, the development of novel viral vectors and plasmid DNA constructs is expected to accelerate. Market data suggests that R&D spending in the GCC biopharmaceutical sector is projected to reach approximately $1 billion by 2026, highlighting the commitment to fostering innovation. Consequently, the viral vectors-and-plasmid-dna-manufacturing market is likely to benefit from the influx of new technologies and methodologies that emerge from these R&D efforts.

Growing Investment in Biotechnology Startups

The viral vectors-and-plasmid-dna-manufacturing market is witnessing a surge in investment directed towards biotechnology startups within the GCC. This influx of capital is primarily fueled by the increasing recognition of the potential of gene therapies and the need for innovative solutions in healthcare. Venture capital firms and government initiatives are actively supporting startups that focus on developing novel viral vectors and plasmid DNA technologies. This trend is indicative of a broader shift towards fostering a vibrant biotechnology ecosystem in the region. As these startups emerge and grow, they are likely to contribute to advancements in manufacturing processes and product offerings, thereby enhancing the overall competitiveness of the viral vectors-and-plasmid-dna-manufacturing market. The potential for collaboration between established companies and startups further amplifies this growth trajectory.

Technological Advancements in Manufacturing Processes

Technological advancements are playing a crucial role in shaping the viral vectors-and-plasmid-dna-manufacturing market. Innovations in bioprocessing technologies, such as improved cell culture systems and purification methods, are enhancing the efficiency and yield of viral vector production. These advancements not only reduce production costs but also increase the scalability of manufacturing processes, making it easier for companies to meet the growing demand for gene therapies. In the GCC region, investments in state-of-the-art manufacturing facilities are on the rise, with several companies adopting automated systems to streamline operations. This shift towards more sophisticated manufacturing techniques is expected to drive market growth, as it allows for the production of higher-quality products that meet regulatory standards. As a result, the viral vectors-and-plasmid-dna-manufacturing market is likely to see increased competitiveness and innovation.