Increased Focus on Water Supply Systems

The Helical Submerged Arc Welded Pipe Market is significantly influenced by the growing emphasis on water supply systems. As urbanization accelerates, the demand for efficient water distribution networks is becoming increasingly critical. Recent statistics suggest that investments in water infrastructure are projected to reach billions of dollars over the next decade. This surge in investment is likely to drive the demand for helical submerged arc welded pipes, which are favored for their durability and resistance to corrosion. Additionally, the need for sustainable water management practices is prompting municipalities to upgrade their existing pipelines, further enhancing the market's growth potential. The Helical Submerged Arc Welded Pipe Market stands to gain from these trends as cities strive to ensure reliable water supply and quality.

Rising Demand for Energy Infrastructure

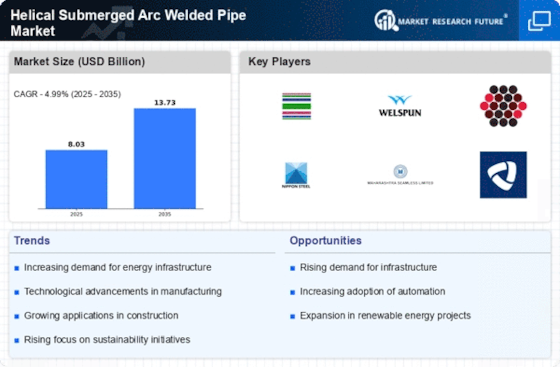

The Helical Submerged Arc Welded Pipe Market is experiencing a notable increase in demand driven by the expansion of energy infrastructure. As countries strive to enhance their energy security, investments in pipelines for oil and gas transportation are surging. According to recent data, the energy sector accounts for a substantial portion of the overall demand for helical submerged arc welded pipes, with projections indicating a growth rate of approximately 5% annually. This trend is likely to continue as nations prioritize energy independence and seek to modernize their existing infrastructure. Furthermore, the shift towards renewable energy sources necessitates the development of new pipelines, further propelling the market. The Helical Submerged Arc Welded Pipe Market is thus positioned to benefit from these ongoing developments in energy infrastructure.

Technological Innovations in Manufacturing

Technological advancements in manufacturing processes are playing a pivotal role in shaping the Helical Submerged Arc Welded Pipe Market. Innovations such as automated welding techniques and improved quality control measures are enhancing production efficiency and product reliability. Recent developments indicate that manufacturers are increasingly adopting advanced technologies to reduce production costs and improve the mechanical properties of pipes. This shift not only meets the rising quality standards but also caters to the diverse needs of various industries, including oil and gas, water supply, and construction. As a result, the Helical Submerged Arc Welded Pipe Market is likely to witness a surge in demand for high-performance pipes that can withstand extreme conditions, thereby driving market growth.

Growing Demand for Oil and Gas Transportation

The Helical Submerged Arc Welded Pipe Market is significantly driven by the escalating demand for oil and gas transportation. As global energy consumption continues to rise, the need for efficient and reliable pipeline systems becomes paramount. Recent data indicates that the oil and gas sector remains one of the largest consumers of helical submerged arc welded pipes, with a projected growth rate of around 4% annually. This trend is further fueled by the exploration of new oil and gas reserves, necessitating the construction of extensive pipeline networks. Additionally, the increasing focus on safety and environmental standards is prompting companies to invest in high-quality piping solutions. Consequently, the Helical Submerged Arc Welded Pipe Market is poised for substantial growth as it caters to the evolving needs of the energy sector.

Regulatory Support for Infrastructure Development

The Helical Submerged Arc Welded Pipe Market is benefiting from favorable regulatory frameworks that support infrastructure development. Governments are increasingly recognizing the importance of modernizing infrastructure to stimulate economic growth and improve public services. Recent policy initiatives have led to increased funding for infrastructure projects, particularly in transportation and utilities. This regulatory support is expected to create a conducive environment for the expansion of the helical submerged arc welded pipe market, as these pipes are essential for various applications, including pipelines and structural components. The anticipated rise in public and private sector investments in infrastructure is likely to bolster the Helical Submerged Arc Welded Pipe Market, providing a solid foundation for future growth.