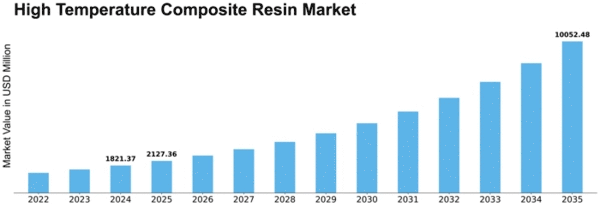

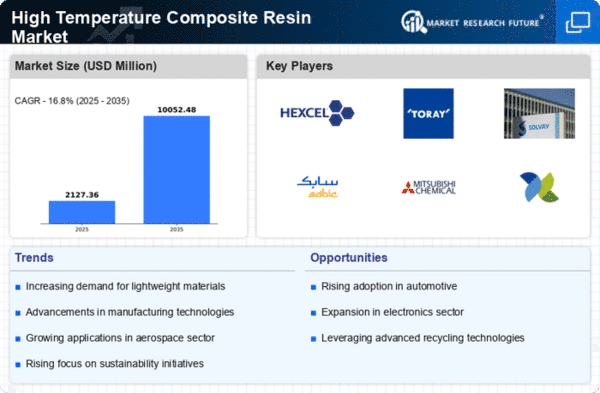

High Temperature Composite Resin Size

High Temperature Composite Resin Market Growth Projections and Opportunities

High-temperature composite resin market size was valued at USD 1.2 Billion in 2021 and is projected to reach USD 2.1 Billion by 2030, growing at a CAGR of 10.4% from 2021 to 2030.

The high-temperature composite resin market is influenced by various factors that shape its dynamics and growth. Market factors encompass a wide range of elements that impact the demand, supply, and overall landscape of these resins.

One crucial factor is the growing demand across industries for lightweight, durable, and heat-resistant materials. High-temperature composite resins fulfill these requirements, making them highly sought-after in aerospace, automotive, electronics, and oil & gas sectors. The need for materials that can withstand extreme temperatures while maintaining structural integrity drives the market forward.

Technological advancements play a pivotal role in shaping the high-temperature composite resin market. Ongoing research and development efforts lead to the innovation of new resin formulations with improved properties. Enhanced heat resistance, mechanical strength, and cost-effectiveness are key areas of focus, driving market expansion as these advanced resins become available.

Another significant market factor is the regulatory landscape and environmental concerns. Stringent regulations regarding emissions and the push for sustainable materials propel the demand for eco-friendly high-temperature composite resins. Manufacturers are increasingly investing in developing bio-based or recyclable resins, aligning with global sustainability goals.

Moreover, the market is greatly influenced by the economic landscape and global trade dynamics. Fluctuations in raw material prices, geopolitical tensions impacting trade, and currency exchange rates directly impact production costs and market competitiveness. Additionally, shifts in consumer preferences towards quality, performance, and cost-effectiveness influence purchasing decisions, shaping market trends.

The competitive landscape and industry collaborations also contribute significantly to the market factors. Companies engage in mergers, acquisitions, and strategic partnerships to enhance their product portfolios, expand their market presence, and gain a competitive edge. Such collaborations often lead to the development of innovative high-temperature composite resin solutions.

Furthermore, the market is sensitive to end-user industries' cyclical nature. For instance, the aerospace industry's demand for high-temperature composite resins might fluctuate based on aircraft production cycles or global economic conditions. Understanding these fluctuations is vital for resin manufacturers to adapt and strategize effectively.

Consumer awareness and education regarding the benefits of high-temperature composite resins also impact market growth. As industries and consumers become more informed about the advantages these resins offer, there is a gradual shift towards their adoption, further driving market expansion.

Leave a Comment