Growth in the Automotive Sector

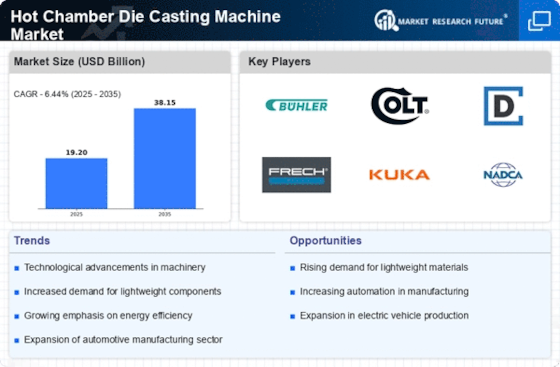

The growth in the automotive sector is a crucial driver for the Hot Chamber Die Casting Machine Market. With the automotive industry increasingly focusing on lightweight and high-performance components, the demand for die casting solutions is on the rise. Hot chamber die casting machines are particularly suited for producing complex geometries and intricate designs required in modern vehicles. The automotive sector's shift towards electric vehicles (EVs) is also contributing to this trend, as EVs often utilize die-cast components for battery housings and structural parts. Market analysts suggest that the automotive industry's expansion could lead to a demand increase for hot chamber die casting machines, potentially reaching a market size of several billion dollars by 2030.

Rising Demand for Lightweight Materials

The increasing demand for lightweight materials in various industries, particularly automotive and aerospace, appears to be a significant driver for the Hot Chamber Die Casting Machine Market. Manufacturers are increasingly adopting aluminum and magnesium alloys due to their favorable strength-to-weight ratios. This trend is likely to enhance the efficiency of vehicles and aircraft, leading to reduced fuel consumption and emissions. As a result, the market for hot chamber die casting machines, which are adept at processing these materials, is expected to witness substantial growth. According to industry estimates, the demand for lightweight components is projected to grow at a compound annual growth rate of over 5% in the coming years, further propelling the hot chamber die casting machine market.

Technological Innovations in Die Casting

Technological innovations in die casting processes are likely to play a pivotal role in shaping the Hot Chamber Die Casting Machine Market. Advancements such as improved automation, enhanced precision, and the integration of Industry 4.0 technologies are transforming traditional die casting methods. These innovations not only increase production efficiency but also improve the quality of the final products. For instance, the introduction of smart sensors and real-time monitoring systems allows manufacturers to optimize their operations, thereby reducing waste and costs. As these technologies become more prevalent, the market for hot chamber die casting machines is expected to expand, with a projected growth rate of approximately 6% annually over the next five years.

Focus on Energy Efficiency and Sustainability

The focus on energy efficiency and sustainability is emerging as a vital driver for the Hot Chamber Die Casting Machine Market. As industries strive to reduce their carbon footprints, there is a growing emphasis on adopting energy-efficient manufacturing processes. Hot chamber die casting machines, known for their lower energy consumption compared to other casting methods, are becoming increasingly attractive to manufacturers. Additionally, the recycling of aluminum and other materials used in die casting aligns with sustainability goals, further enhancing the appeal of these machines. Market Research Future predict that the shift towards sustainable manufacturing practices could lead to a market growth rate of around 5% annually, as companies seek to meet regulatory requirements and consumer expectations.

Increased Investment in Manufacturing Infrastructure

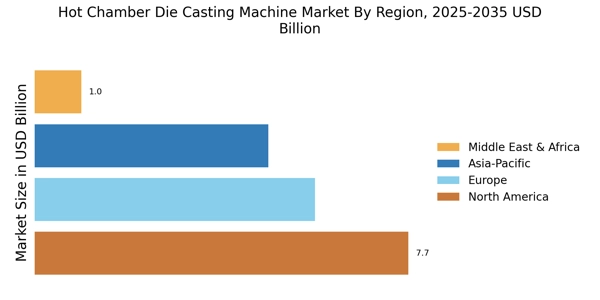

Increased investment in manufacturing infrastructure is likely to bolster the Hot Chamber Die Casting Machine Market. Governments and private entities are investing heavily in modernizing manufacturing facilities to enhance productivity and competitiveness. This trend is particularly evident in regions where industrialization is accelerating, leading to a higher demand for advanced manufacturing technologies, including hot chamber die casting machines. The establishment of new manufacturing plants and the upgrading of existing facilities are expected to create a favorable environment for the adoption of these machines. Reports indicate that investments in manufacturing infrastructure could exceed trillions of dollars over the next decade, thereby significantly impacting the hot chamber die casting machine market.