Regulatory Compliance

Regulatory compliance is a critical driver in the Industrial Belt Scale Market, as industries face stringent regulations regarding weight measurement accuracy. Governments and regulatory bodies are enforcing standards that require precise weight measurements to ensure safety and quality in various sectors, including food and pharmaceuticals. The demand for compliant weighing solutions is expected to grow, with an estimated increase of 15% in the market for certified industrial scales. This trend underscores the importance of investing in advanced belt scales that meet regulatory requirements, thereby ensuring that companies avoid penalties and maintain their market reputation.

Sustainability Initiatives

Sustainability initiatives are increasingly influencing the Industrial Belt Scale Market, as companies seek to reduce their environmental footprint. The push for eco-friendly practices is driving the adoption of energy-efficient weighing solutions that minimize waste and optimize resource use. Recent studies indicate that the market for sustainable industrial scales is expected to grow by 18% over the next five years. This growth is attributed to the rising awareness of environmental issues and the need for companies to comply with sustainability regulations. As a result, manufacturers are focusing on developing belt scales that not only meet performance standards but also align with sustainability goals.

Technological Advancements

The Industrial Belt Scale Market is experiencing a surge in technological advancements that enhance measurement accuracy and efficiency. Innovations such as digital load cells and advanced software integration are becoming increasingly prevalent. These technologies not only improve the precision of weight measurements but also facilitate real-time data analysis, which is crucial for operational efficiency. According to recent data, the adoption of smart scales is projected to increase by 25% over the next five years, driven by the need for automation in manufacturing processes. This trend indicates a shift towards more sophisticated systems that can seamlessly integrate with existing industrial operations, thereby optimizing productivity and reducing operational costs.

Rising Demand for Automation

The Industrial Belt Scale Market is witnessing a rising demand for automation across various sectors, including manufacturing, logistics, and mining. As industries strive to enhance operational efficiency and reduce labor costs, automated belt scales are becoming essential. The market for automated weighing solutions is projected to grow by 20% in the next few years, driven by the need for faster and more accurate measurements. This shift towards automation not only streamlines processes but also minimizes human error, thereby improving overall productivity. Companies are increasingly investing in integrated systems that combine weighing and data management, reflecting a broader trend towards smart manufacturing.

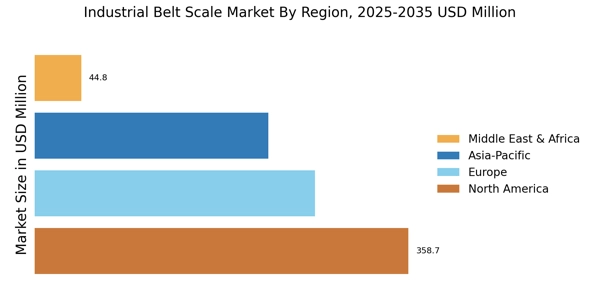

Market Expansion in Emerging Economies

The Industrial Belt Scale Market is poised for expansion in emerging economies, where industrialization is rapidly increasing. Countries in Asia and Africa are investing heavily in infrastructure development, leading to a heightened demand for industrial equipment, including belt scales. Market analysts project a growth rate of 22% in these regions over the next few years, driven by the need for efficient material handling and processing solutions. This trend presents significant opportunities for manufacturers to penetrate new markets and establish a presence in regions that are experiencing economic growth. As industries in these areas modernize, the demand for reliable and accurate weighing solutions will likely continue to rise.

Leave a Comment