Growth of the Textile Industry

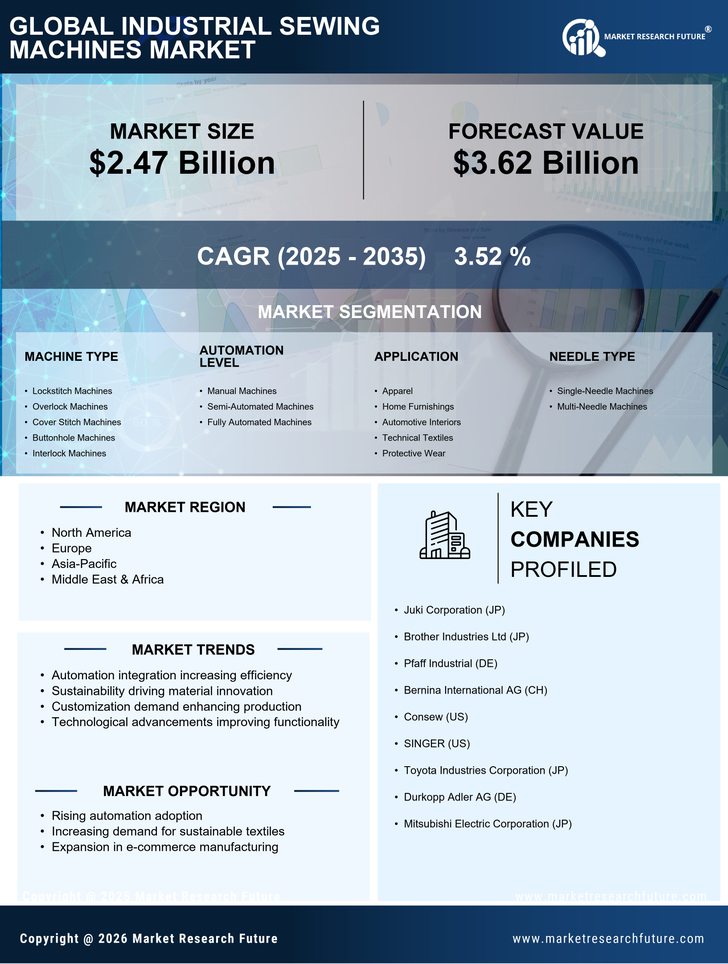

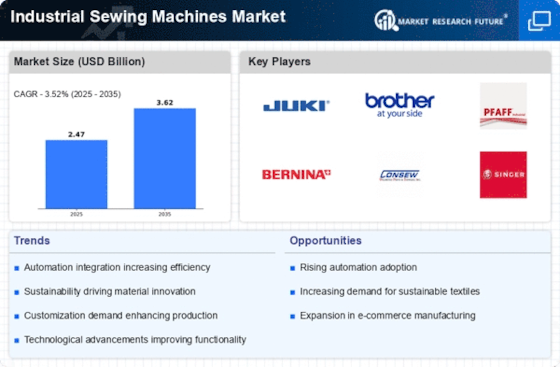

The Industrial Sewing Machines Market is significantly influenced by the growth of the textile industry. As the demand for textiles increases, manufacturers are compelled to invest in advanced sewing machines to keep pace with production requirements. The textile industry is projected to reach a market value of approximately 1 trillion USD by 2025, indicating a strong upward trend. This growth is driven by various factors, including rising consumer preferences for diverse textile products and the expansion of e-commerce platforms. Consequently, the Industrial Sewing Machines Market benefits from this expansion, as manufacturers seek to enhance their production capabilities. The need for high-quality, durable, and efficient sewing machines becomes paramount, suggesting that the market will continue to thrive in response to the textile industry's growth.

Rising Demand for Apparel Manufacturing

The Industrial Sewing Machines Market experiences a notable surge in demand driven by the growing apparel manufacturing sector. As fashion trends evolve, manufacturers are increasingly seeking efficient and high-performance sewing machines to meet production needs. In 2025, the apparel industry is projected to reach a market value of approximately 1.5 trillion USD, indicating a robust growth trajectory. This demand for apparel manufacturing directly influences the Industrial Sewing Machines Market, as companies invest in advanced machinery to enhance productivity and reduce lead times. Furthermore, the shift towards fast fashion necessitates the adoption of innovative sewing technologies, thereby propelling the market forward. The need for speed and efficiency in production processes is likely to continue driving investments in industrial sewing machines, suggesting a sustained growth outlook for the industry.

Customization and Personalization Trends

The trend towards customization and personalization is reshaping the Industrial Sewing Machines Market. As consumers seek unique and tailored products, manufacturers are compelled to adapt their production processes to meet these demands. This shift is particularly evident in sectors such as fashion and home textiles, where personalized items are gaining popularity. In 2025, the market for customized textile products is projected to grow by over 10%, indicating a strong consumer preference for individualized offerings. To capitalize on this trend, manufacturers are investing in versatile sewing machines that can accommodate a range of customization options. This adaptability not only enhances customer satisfaction but also drives sales, suggesting that the Industrial Sewing Machines Market will continue to evolve in response to these changing consumer preferences.

Focus on Sustainable Manufacturing Practices

Sustainability has emerged as a critical focus within the Industrial Sewing Machines Market. Manufacturers are increasingly adopting eco-friendly practices, which include the use of sustainable materials and energy-efficient machinery. This shift is driven by consumer demand for environmentally responsible products and the need to comply with stringent regulations. In 2025, it is anticipated that the market for sustainable sewing machines will grow by approximately 15%, reflecting the industry's commitment to reducing its environmental footprint. Companies that prioritize sustainability are likely to gain a competitive edge, as consumers increasingly favor brands that align with their values. This focus on sustainable manufacturing practices is expected to be a significant driver for the Industrial Sewing Machines Market, as it encourages innovation and the development of greener technologies.

Technological Advancements in Sewing Machines

Technological advancements play a pivotal role in shaping the Industrial Sewing Machines Market. Innovations such as automation, computerization, and smart sewing technologies are transforming traditional sewing processes. The integration of artificial intelligence and machine learning into sewing machines enhances precision and efficiency, allowing manufacturers to produce high-quality products at a faster pace. In 2025, it is estimated that the market for automated sewing machines will grow by over 20%, reflecting the industry's shift towards more sophisticated machinery. These advancements not only improve operational efficiency but also reduce labor costs, making them attractive to manufacturers. As the industry continues to evolve, the adoption of cutting-edge technologies is expected to remain a key driver for growth in the Industrial Sewing Machines Market.