Rising Demand for Automation

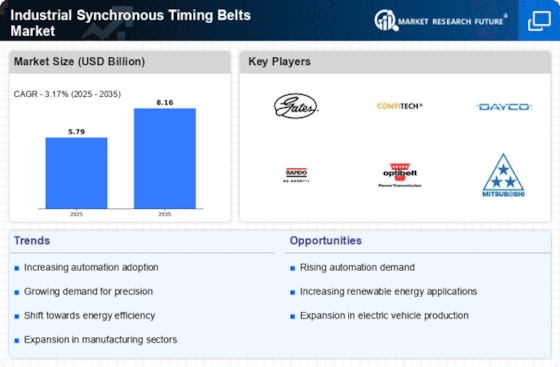

The Industrial Synchronous Timing Belts Market experiences a notable surge in demand due to the increasing adoption of automation across various sectors. Industries such as manufacturing, automotive, and food processing are integrating automated systems to enhance efficiency and reduce operational costs. This trend is reflected in the projected growth of the automation market, which is expected to reach USD 300 billion by 2026. As companies seek to optimize their production processes, the reliance on synchronous timing belts, which provide precise timing and synchronization, becomes paramount. Consequently, this growing demand for automation is likely to drive the Industrial Synchronous Timing Belts Market forward, as manufacturers strive to meet the needs of automated machinery.

Expansion of Manufacturing Sector

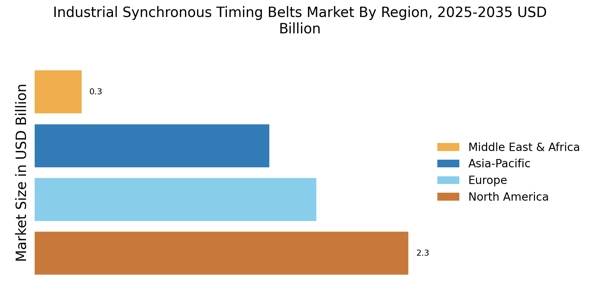

The Industrial Synchronous Timing Belts Market is poised for growth, largely driven by the expansion of the manufacturing sector. As countries invest in infrastructure and industrial development, the demand for machinery and equipment rises, subsequently increasing the need for reliable timing belts. For instance, the manufacturing sector in regions such as Asia-Pacific is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2028. This expansion necessitates the use of synchronous timing belts, which are essential for ensuring the smooth operation of various machinery. Thus, the growth of the manufacturing sector directly correlates with the demand for products within the Industrial Synchronous Timing Belts Market.

Growing Focus on Energy Efficiency

The Industrial Synchronous Timing Belts Market is increasingly influenced by the growing focus on energy efficiency. As industries strive to reduce their carbon footprint and operational costs, the demand for energy-efficient solutions is on the rise. Synchronous timing belts, known for their ability to transmit power with minimal energy loss, are becoming a preferred choice for many applications. According to recent studies, energy-efficient machinery can reduce energy consumption by up to 30%. This shift towards energy efficiency not only aligns with global sustainability goals but also enhances the competitiveness of businesses. Consequently, the emphasis on energy-efficient solutions is expected to propel the Industrial Synchronous Timing Belts Market forward.

Increased Investment in Renewable Energy

The Industrial Synchronous Timing Belts Market is likely to benefit from increased investment in renewable energy sources. As countries transition towards sustainable energy solutions, the demand for equipment and machinery that supports renewable energy generation is growing. Synchronous timing belts are integral components in various renewable energy applications, including wind turbines and solar tracking systems. The renewable energy sector is projected to witness substantial growth, with investments expected to exceed USD 1 trillion by 2025. This influx of investment not only stimulates the demand for synchronous timing belts but also encourages manufacturers to innovate and develop products tailored for the renewable energy market. Thus, the Industrial Synchronous Timing Belts Market stands to gain from this trend.

Technological Innovations in Belt Design

Technological innovations play a crucial role in shaping the Industrial Synchronous Timing Belts Market. Recent advancements in materials and design have led to the development of belts that offer enhanced durability, efficiency, and performance. For example, the introduction of high-performance polyurethane belts has improved resistance to wear and tear, making them suitable for demanding applications. Furthermore, the integration of smart technologies, such as sensors and IoT capabilities, into timing belts is gaining traction. These innovations not only improve operational efficiency but also provide real-time monitoring capabilities. As manufacturers continue to innovate, the Industrial Synchronous Timing Belts Market is likely to benefit from increased adoption of these advanced products.