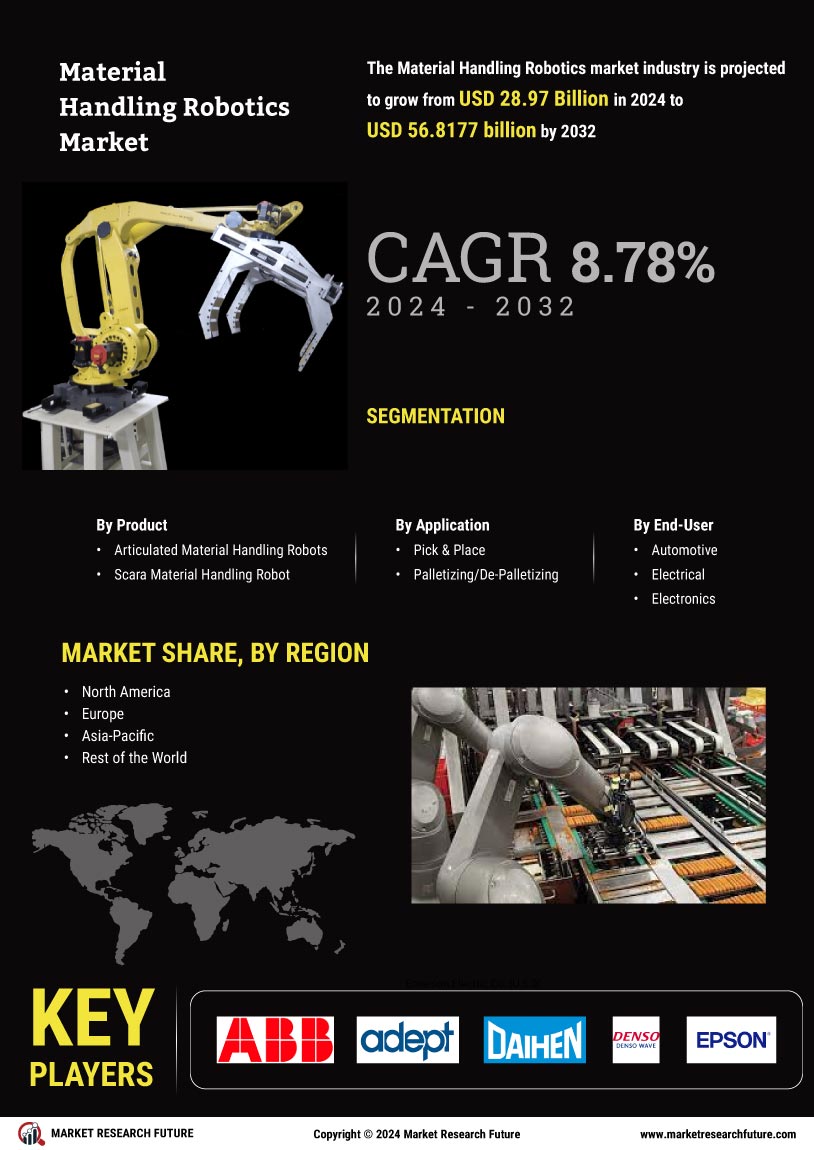

Material Handling Robotics Market Summary

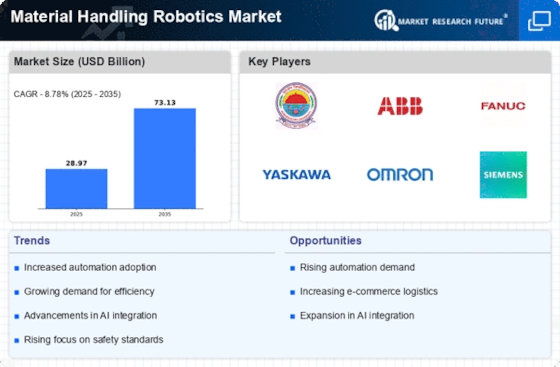

As per MRFR analysis, the Material Handling Robotics Market Size was estimated at 28.97 USD Billion in 2024. The Material Handling Robotics industry is projected to grow from 31.51 USD Billion in 2025 to 73.13 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 8.78 during the forecast period 2025 - 2035.

Key Market Trends & Highlights

The Material Handling Robotics Market is experiencing robust growth driven by automation and technological advancements.

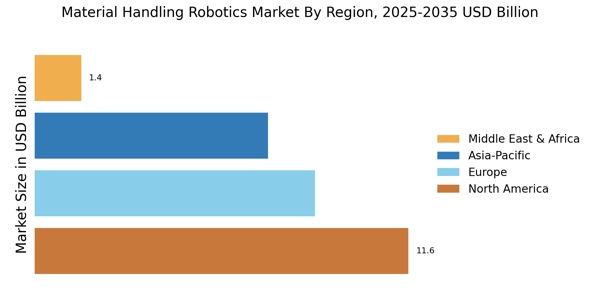

- North America remains the largest market for material handling robotics, reflecting a strong demand for automation across various industries.

- Asia-Pacific is identified as the fastest-growing region, propelled by rapid industrialization and increasing investments in robotics technology.

- Articulated material handling robots dominate the market, while Scara robots are emerging as the fastest-growing segment due to their versatility and efficiency.

- Key market drivers include the rising demand for efficiency and the challenges posed by labor shortages, which are pushing companies to adopt advanced robotic solutions.

Market Size & Forecast

| 2024 Market Size | 28.97 (USD Billion) |

| 2035 Market Size | 73.13 (USD Billion) |

| CAGR (2025 - 2035) | 8.78% |

Major Players

KUKA (DE), ABB (CH), FANUC (JP), Yaskawa (JP), Omron (JP), Siemens (DE), JBT Corporation (US), Daifuku (JP), Honeywell (US), Cognex (US)

Leave a Comment