Increased Adoption of Automation

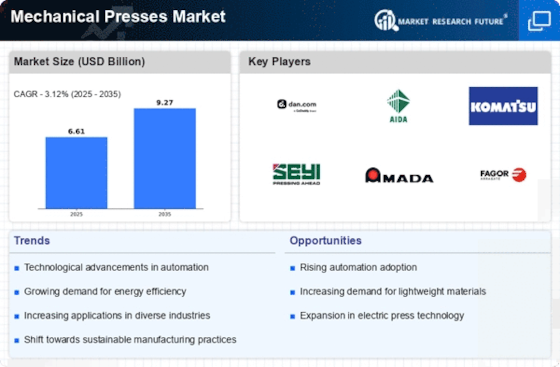

The Mechanical Presses Market is witnessing a significant transformation due to the increased adoption of automation technologies. Manufacturers are integrating automated systems with mechanical presses to enhance productivity and reduce labor costs. This trend is particularly evident in industries such as aerospace and electronics, where precision and efficiency are paramount. By 2025, it is anticipated that the integration of automation will lead to a 10% increase in the operational efficiency of mechanical presses. As companies seek to optimize their manufacturing processes, the demand for automated mechanical presses is likely to rise, thereby propelling the growth of the Mechanical Presses Market. This shift not only improves production rates but also minimizes human error, further solidifying the role of mechanical presses in modern manufacturing.

Growing Focus on Energy Efficiency

The Mechanical Presses Market is increasingly influenced by a growing focus on energy efficiency among manufacturers. As energy costs continue to rise, companies are seeking ways to reduce their operational expenses. Mechanical presses, particularly those designed with energy-efficient technologies, are becoming more attractive options. In 2025, it is estimated that energy-efficient mechanical presses could reduce energy consumption by up to 30%, making them a cost-effective solution for manufacturers. This trend aligns with broader sustainability goals, as companies aim to minimize their environmental impact. The Mechanical Presses Market is likely to see a shift towards presses that not only meet production needs but also adhere to energy efficiency standards, thereby appealing to environmentally conscious consumers and businesses alike.

Rising Demand in Automotive Sector

The Mechanical Presses Market is experiencing a notable surge in demand, particularly driven by the automotive sector. As manufacturers strive to enhance production efficiency and reduce costs, mechanical presses are increasingly favored for their ability to deliver high precision and speed in metal forming processes. In 2025, the automotive industry is projected to account for a substantial share of the mechanical presses market, with estimates suggesting a growth rate of approximately 5% annually. This trend is likely to be fueled by the ongoing shift towards electric vehicles, which require advanced manufacturing techniques. Consequently, the Mechanical Presses Market is poised to benefit from the automotive sector's evolution, as companies invest in modernizing their production lines to meet the demands of a changing market.

Expansion of the Electronics Industry

The Mechanical Presses Market is benefiting from the expansion of the electronics industry, which demands high-precision components and efficient manufacturing processes. As consumer electronics continue to evolve, the need for advanced manufacturing techniques becomes increasingly critical. Mechanical presses are essential in producing intricate parts for devices such as smartphones, tablets, and wearables. By 2025, the electronics sector is projected to contribute significantly to the mechanical presses market, with a growth rate of around 6% annually. This expansion is likely to drive innovation within the Mechanical Presses Market, as manufacturers develop specialized presses tailored to the unique requirements of electronic components, thereby enhancing their competitive edge.

Emerging Markets and Infrastructure Development

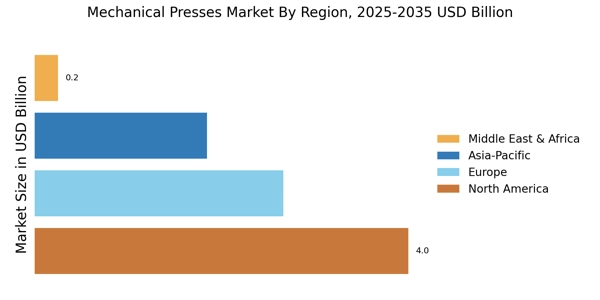

The Mechanical Presses Market is poised for growth due to emerging markets and ongoing infrastructure development. Countries in Asia and South America are investing heavily in industrialization and infrastructure projects, which in turn drives the demand for mechanical presses. As these regions develop their manufacturing capabilities, the need for efficient and reliable machinery becomes paramount. By 2025, it is expected that emerging markets will account for a significant portion of the mechanical presses market, with a projected growth rate of 7% annually. This trend indicates a robust opportunity for manufacturers within the Mechanical Presses Market to expand their reach and cater to the evolving needs of these developing economies.