Focus on Energy Efficiency

Energy efficiency is becoming a pivotal concern within the Metal Processing Machine Market. Manufacturers are increasingly seeking machines that not only enhance productivity but also reduce energy consumption. The push for sustainable manufacturing practices is driving the development of energy-efficient metal processing machines. Recent studies indicate that energy-efficient machines can reduce operational costs by up to 25%, making them an attractive investment for manufacturers. This focus on energy efficiency aligns with broader sustainability initiatives, further propelling the growth of the Metal Processing Machine Market as companies strive to minimize their environmental impact.

Technological Advancements

The Metal Processing Machine Market is experiencing a surge in technological advancements, which are enhancing the efficiency and precision of metal processing operations. Innovations such as computer numerical control (CNC) technology and advanced robotics are becoming increasingly prevalent. These technologies allow for higher levels of automation, reducing human error and increasing production rates. According to recent data, the adoption of CNC machines has led to a 20% increase in productivity in various manufacturing sectors. Furthermore, the integration of artificial intelligence in metal processing machines is expected to optimize operational workflows, thereby driving growth in the Metal Processing Machine Market.

Growth in Construction Activities

The Metal Processing Machine Market is significantly influenced by the growth in construction activities across various regions. As infrastructure development accelerates, the demand for metal components used in construction is on the rise. Metal processing machines are essential for fabricating structural steel, reinforcing bars, and other critical materials. Recent statistics suggest that construction spending has increased by 15% in several regions, leading to a corresponding rise in the demand for metal processing equipment. This trend indicates a robust growth trajectory for the Metal Processing Machine Market, as manufacturers seek to meet the needs of the expanding construction sector.

Rising Demand from Automotive Sector

The automotive sector is a major driver for the Metal Processing Machine Market, as it requires high-quality metal components for vehicle manufacturing. The demand for lightweight and durable materials is pushing manufacturers to invest in advanced metal processing technologies. In recent years, the automotive industry has seen a shift towards electric vehicles, which necessitates the use of specialized metal components. This transition is likely to increase the demand for metal processing machines capable of handling new materials and designs. Market data indicates that the automotive sector accounts for approximately 30% of the total demand for metal processing machines, highlighting its critical role in the industry.

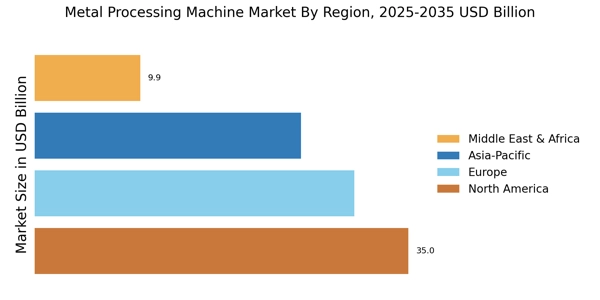

Emerging Markets and Economic Development

Emerging markets are playing a crucial role in the expansion of the Metal Processing Machine Market. As economies develop, there is a growing need for advanced manufacturing capabilities, which includes the adoption of modern metal processing technologies. Countries in Asia and South America are witnessing increased investments in manufacturing infrastructure, leading to a higher demand for metal processing machines. Market analysis shows that these regions are expected to contribute significantly to the overall growth of the industry, with projections indicating a compound annual growth rate of 8% over the next five years. This trend underscores the potential for the Metal Processing Machine Market to thrive in developing economies.