Expansion of End-Use Industries

The Metallurgical Additive Market is benefiting from the expansion of various end-use industries, including automotive, aerospace, and construction. As these sectors continue to grow, the demand for advanced materials and metallurgical additives is expected to increase correspondingly. For instance, the automotive industry is projected to witness a growth rate of 5% annually, driven by the need for innovative materials that enhance vehicle performance and safety. This expansion creates opportunities for metallurgical additives that improve material properties and processing efficiency. Furthermore, as construction projects become more complex, the need for specialized additives that meet specific performance criteria is likely to rise. This broadening of end-use applications serves as a catalyst for growth within the Metallurgical Additive Market.

Rising Demand for Lightweight Materials

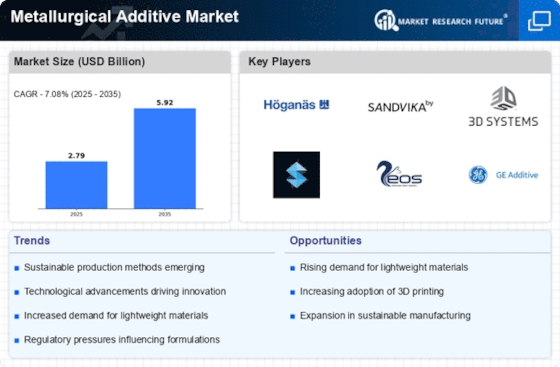

The Metallurgical Additive Market is experiencing a notable surge in demand for lightweight materials, particularly in sectors such as aerospace and automotive. As manufacturers strive to enhance fuel efficiency and reduce emissions, the adoption of lightweight alloys and composites becomes increasingly critical. This trend is supported by data indicating that the aerospace sector alone is projected to grow at a compound annual growth rate of approximately 4.5% through 2027. Consequently, metallurgical additives that facilitate the production of these materials are likely to see heightened demand, as they play a pivotal role in achieving the desired mechanical properties while minimizing weight. This shift towards lightweight solutions not only aligns with regulatory pressures but also reflects a broader industry movement towards innovation and efficiency, thereby propelling the Metallurgical Additive Market forward.

Advancements in 3D Printing Technologies

The Metallurgical Additive Market is significantly influenced by advancements in 3D printing technologies, which have revolutionized the manufacturing landscape. The integration of metallurgical additives in additive manufacturing processes allows for the creation of complex geometries and customized components that were previously unattainable. Recent data suggests that the additive manufacturing market is expected to reach USD 35 billion by 2027, with metallurgical additives playing a crucial role in this growth. These innovations not only enhance production efficiency but also reduce material waste, aligning with sustainability goals. As industries increasingly adopt 3D printing for prototyping and production, the demand for specialized metallurgical additives is likely to escalate, further driving the Metallurgical Additive Market.

Increased Investment in Research and Development

Investment in research and development within the Metallurgical Additive Market is on the rise, as companies seek to innovate and improve product offerings. This trend is particularly evident in sectors such as aerospace, automotive, and medical devices, where the need for advanced materials is paramount. Data indicates that R&D spending in the materials sector is projected to grow by 6% annually, reflecting a commitment to developing new metallurgical additives that enhance performance and sustainability. This focus on innovation not only fosters competitive advantage but also addresses the evolving needs of end-users, thereby propelling the Metallurgical Additive Market forward. As companies strive to meet stringent regulatory requirements and consumer expectations, the emphasis on R&D is likely to remain a key driver of market growth.

Growing Focus on Sustainability and Eco-Friendly Solutions

The Metallurgical Additive Market is increasingly shaped by a growing focus on sustainability and eco-friendly solutions. As industries face mounting pressure to reduce their environmental footprint, the demand for metallurgical additives that support sustainable practices is likely to rise. This includes the development of recyclable materials and processes that minimize waste. Recent studies indicate that the market for sustainable materials is expected to grow at a CAGR of 8% through 2026, highlighting the potential for metallurgical additives that align with these trends. Companies that prioritize sustainability in their product offerings may gain a competitive edge, as consumers and regulatory bodies alike favor environmentally responsible solutions. This shift towards sustainability is poised to be a significant driver in the Metallurgical Additive Market.